BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

After considerable experimentation, fabrication of a backplate for a collet chuck and fabrication of a compound DRO for my lathe, here is the assembly process for the flywheels with details for newcomers. Old hands will find this a trivial part and a boring exposition. :big:

Start out slicing the rough stock. I'm using my DeWalt Multicutter carbide saw to do this. Each slug is about 1" long. I deburr one end of each slug with a Roloc wheel that has some 80 grit and an air die grinder. You just want to knock the rough edge off so it doesn't interfere with the collet...

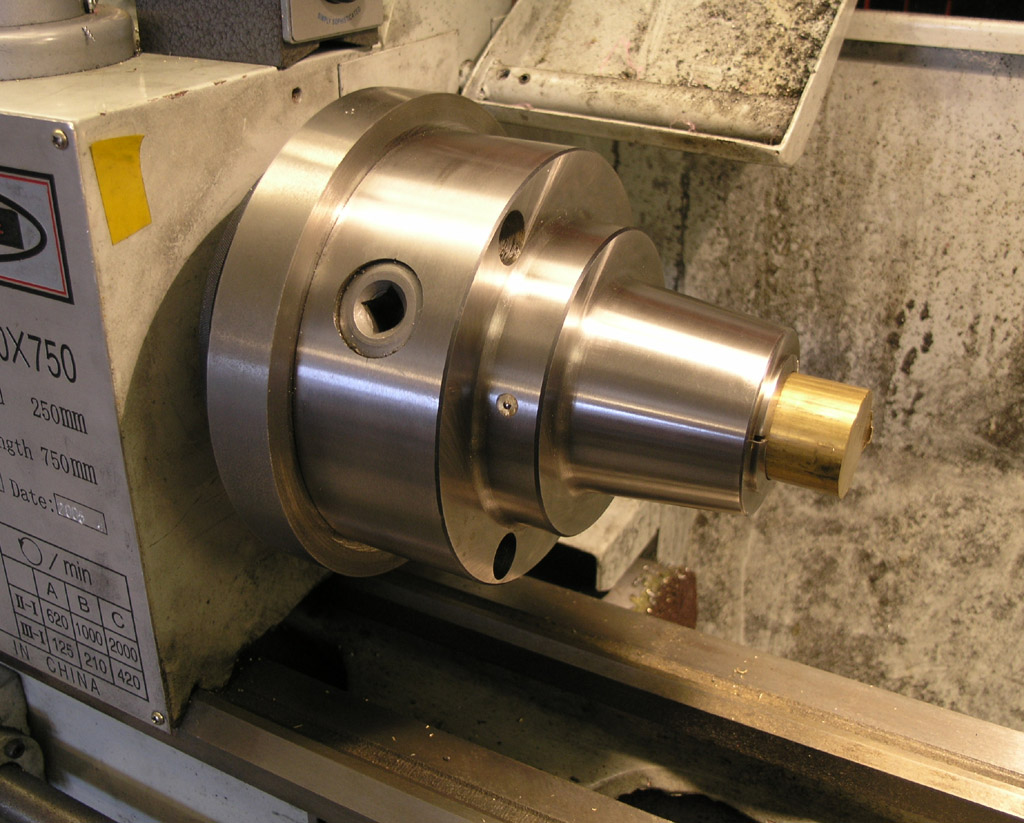

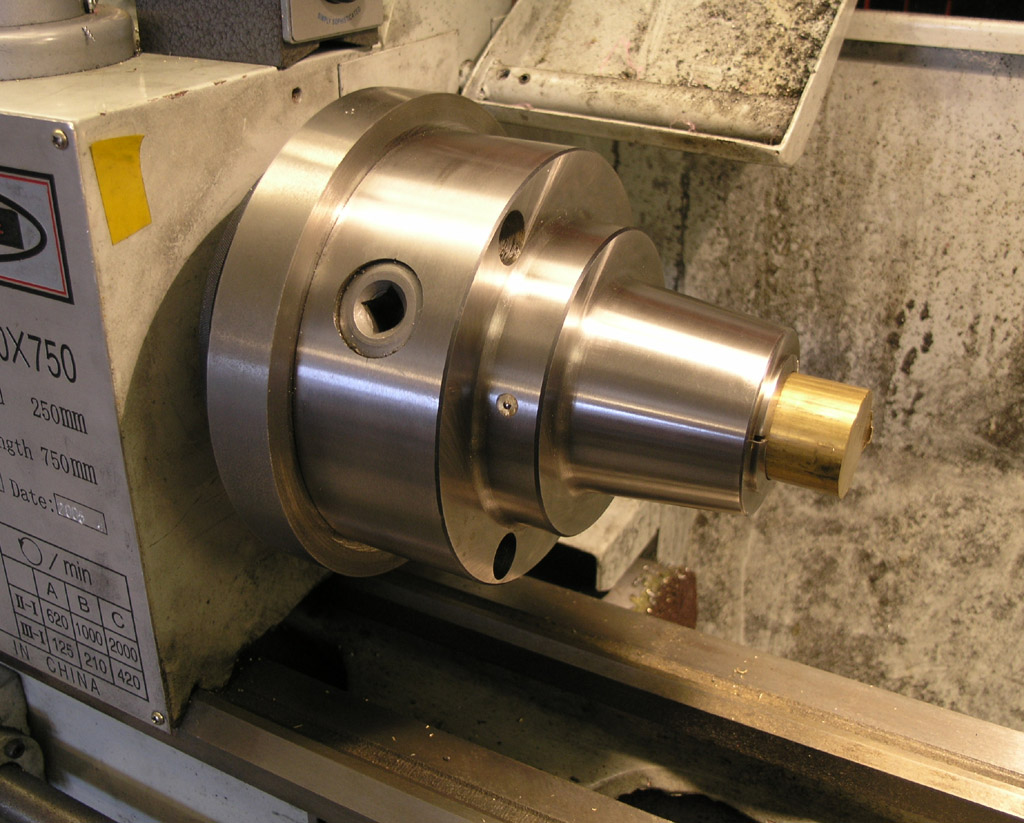

Inset the deburred edge into the collet and tighten in the chuck...

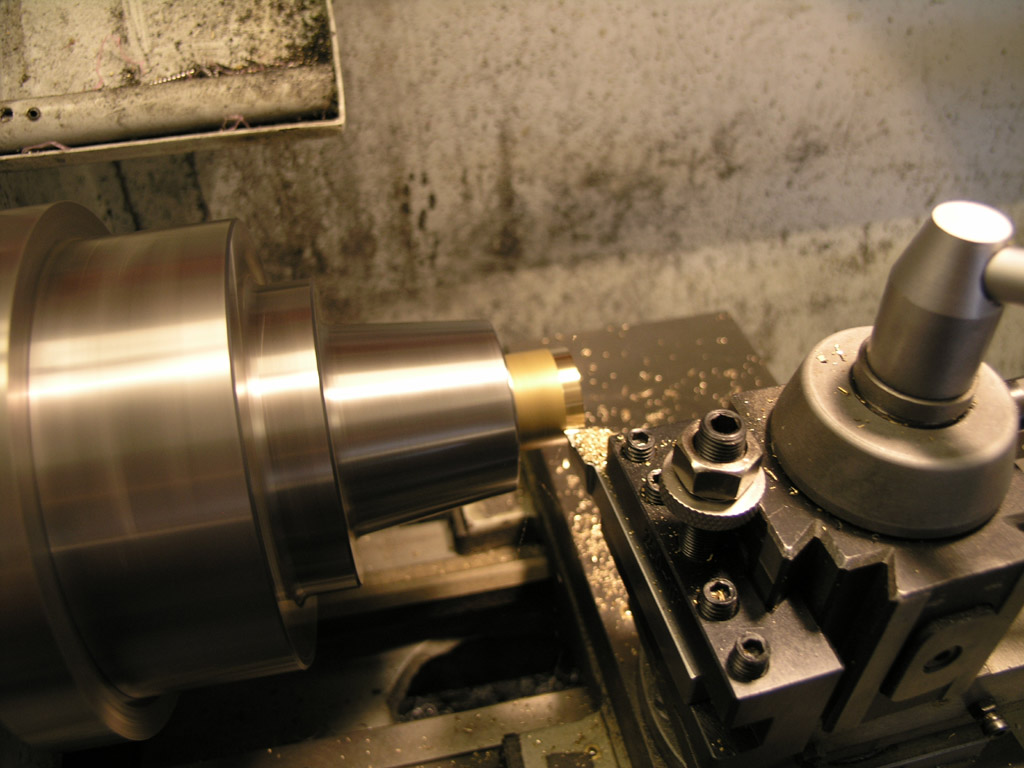

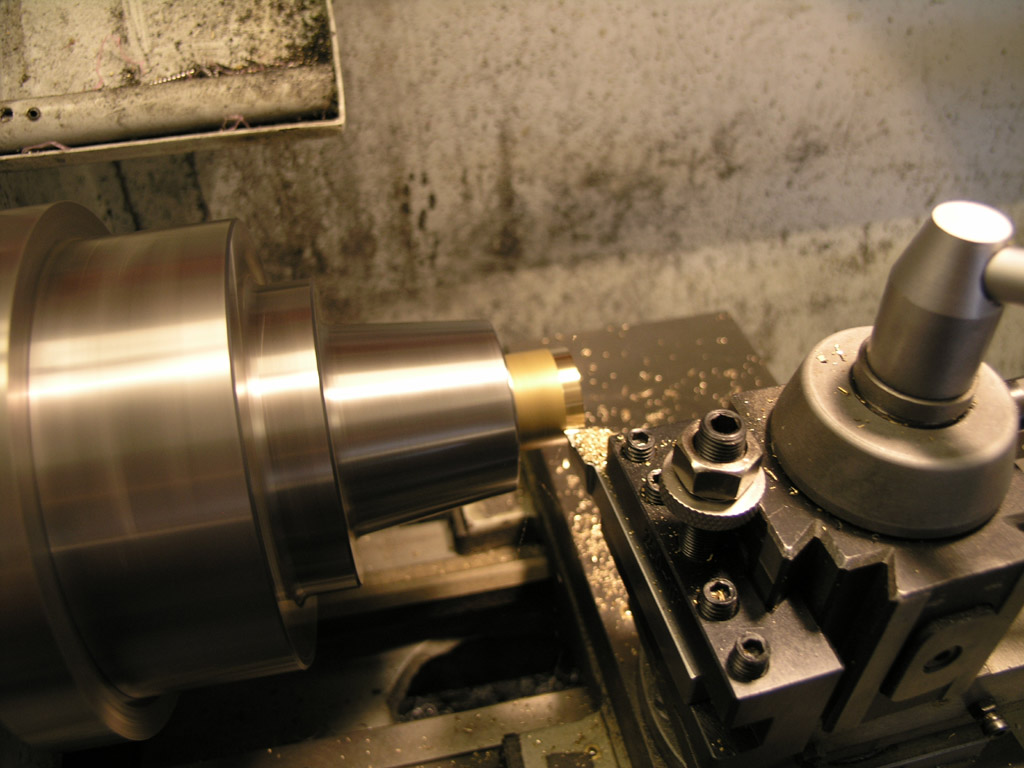

First operation is facing. Just take enough so the whole diameter is faced. This is a good time to fine tune the tool height to minimize the nub in the center...

Now turn the piece. Just take off enough so it is round and machined all over. Don't run into the collet!

<continued>

Start out slicing the rough stock. I'm using my DeWalt Multicutter carbide saw to do this. Each slug is about 1" long. I deburr one end of each slug with a Roloc wheel that has some 80 grit and an air die grinder. You just want to knock the rough edge off so it doesn't interfere with the collet...

Inset the deburred edge into the collet and tighten in the chuck...

First operation is facing. Just take enough so the whole diameter is faced. This is a good time to fine tune the tool height to minimize the nub in the center...

Now turn the piece. Just take off enough so it is round and machined all over. Don't run into the collet!

<continued>