Hi All,

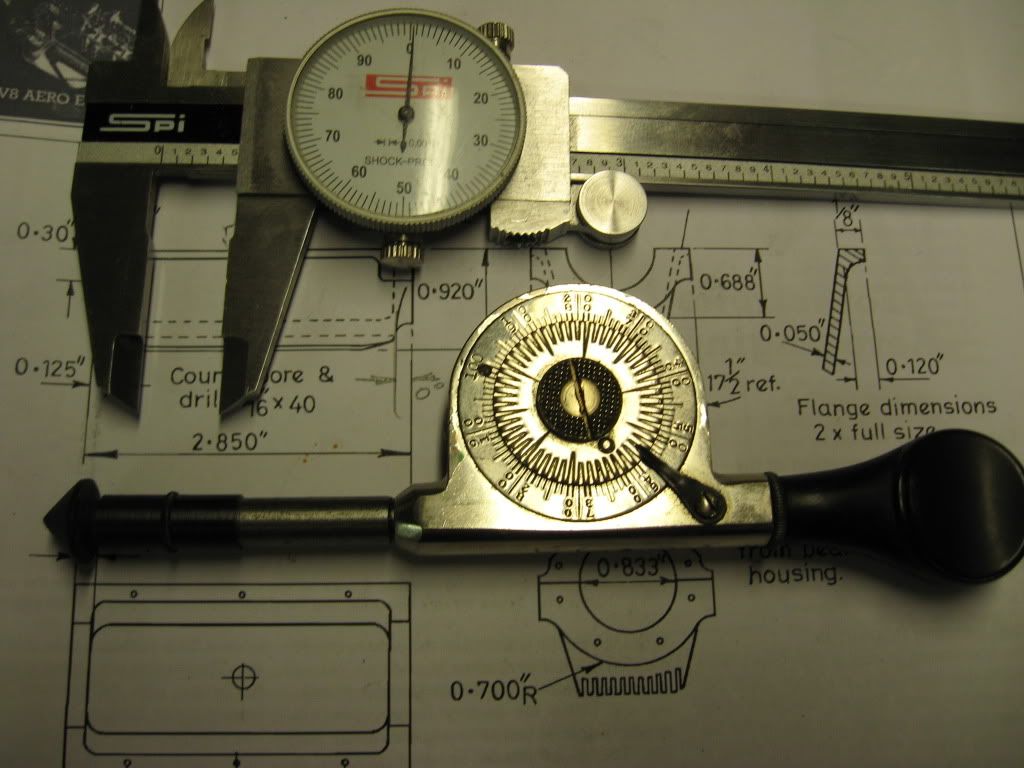

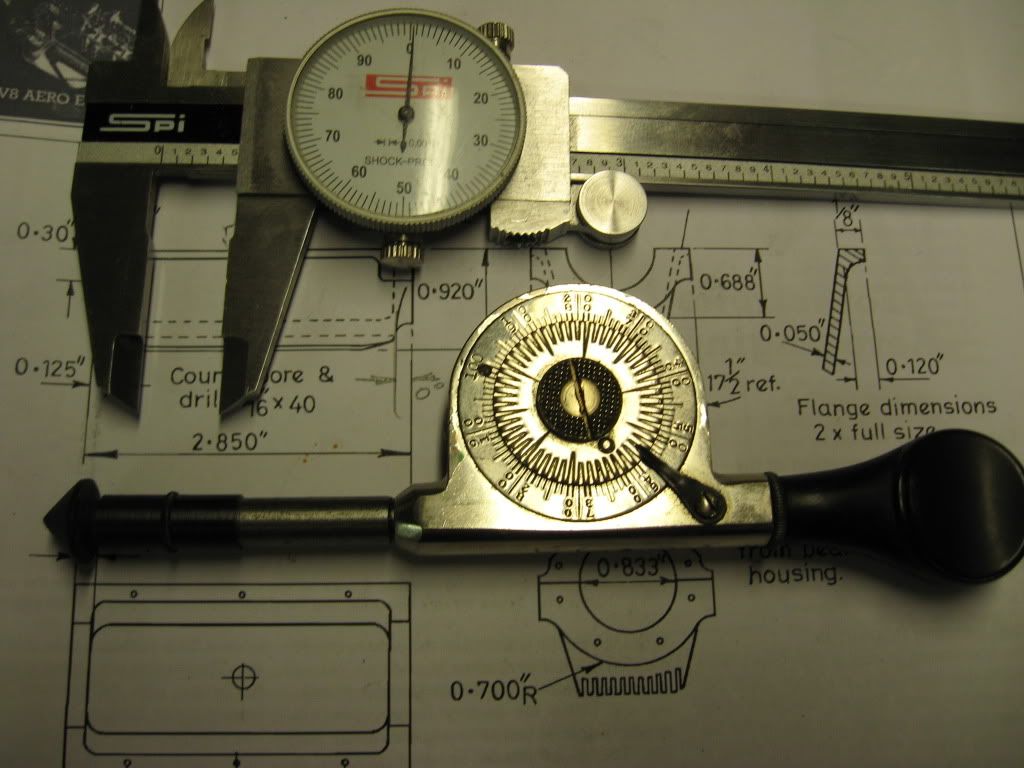

My dad was a machinist/ die maker in the 1930's/40's and I have his old tool box. In there I found this Tach. I can't figure how na heck how to use it. The needle just keeps going and going and going. Can anybody explain how it works.

Thanks

Tony

My dad was a machinist/ die maker in the 1930's/40's and I have his old tool box. In there I found this Tach. I can't figure how na heck how to use it. The needle just keeps going and going and going. Can anybody explain how it works.

Thanks

Tony