Looks great. Your in up to your a$$ now!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SX3 Conversion

- Thread starter 1hand

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

mnewsholme

Member

- Joined

- Jul 24, 2008

- Messages

- 20

- Reaction score

- 0

Im working from basically the same set of plans but for an x3. just wait till you see the hunk of aluminium you need for the x axis motor mount ;D

matt

matt

Matt;mnewsholme said:Im working from basically the same set of plans but for an x3. just wait till you see the hunk of aluminium you need for the x axis motor mount ;D

matt

What are you going to use for X and Y axis steppers? 23's or 34's?

Matt

Steve I've been looking at Mcmaster Carr for the ball screws. Could you give me the part numbers I need? Is it a 5/8 screw? Do I need the round nuts or the square? Doesn't look like the round ones come in 5/8". I thought that beings I'll have everything apart I would put them in right away. By going the way you said, I would be able to afford them right away. Verses the $400 kit version I would have to wait.

Thanks Matt

Thanks Matt

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

you may want to look here

http://www.roton.com/Mating_Components.aspx?family=7059321

the McMaster Car # for the ball screw is 5966k26 for the ball screw and 5966K16 for the ball nut.

Tin

http://www.roton.com/Mating_Components.aspx?family=7059321

the McMaster Car # for the ball screw is 5966k26 for the ball screw and 5966K16 for the ball nut.

Tin

Thanks Tin;

I need a bit of explanation here. Do I then make a mounting block with the 15/16-16 thread in one end, and then screw that square style ball nut into the mounting block? If so, what holds the ball nut from unthreading when the ball screw is going in that direction? Set screws in from the side?

Thanks Matt

I need a bit of explanation here. Do I then make a mounting block with the 15/16-16 thread in one end, and then screw that square style ball nut into the mounting block? If so, what holds the ball nut from unthreading when the ball screw is going in that direction? Set screws in from the side?

Thanks Matt

1 other question I have if someone would like to chime in. I only have a lap top, and was wondering what sort of computer I need for the CNC to run Mach, CAM, and a Gecko drive? I thought I read some where that a laptop won't work. I know little to none about computers also, so I'll like to get a plug and play unit as much as possible. So where do I go and What do I get?

Matt

Matt

1hand said:Thanks Tin;

I need a bit of explanation here. Do I then make a mounting block with the 15/16-16 thread in one end, and then screw that square style ball nut into the mounting block? If so, what holds the ball nut from unthreading when the ball screw is going in that direction? Set screws in from the side?

Thanks Matt

I just tightened the nut well and having the recirc tube on top is best. There wont be much twisting force on the nut. Most of the force will be along the axis as thrust.

There will be some form of block to screw the nut into. Design so the block wont flex when the screw pulls and pushes on it. I also tried to tuck the nut in so travel would be maximized.

1hand said:I only have a lap top, and was wondering what sort of computer I need for the CNC to run Mach, CAM, and a Gecko drive? I thought I read some where that a laptop won't work. I know little to none about computers also

I have an old 1.8 gig CPU and XP.

This is right off the mach site.

Mach3 Minimum Requirements:

◦32-bit version of Windows 2000, Windows XP, Windows Vista, or Windows 7 Operating System

◦1Ghz CPU

◦512MB RAM

◦Non-integrated Video Card with 32MB RAM

◦Basic Computer Skills (ability to copy/rename files, browse directories, etc)

◦Desktop PC (if using the Mach3 Parallel Port Driver - laptops are not supported because the power saving features of the chipsets disrupt the pulse stream, PCMCIA and USB parallel adaptors will *not* work.)

mnewsholme

Member

- Joined

- Jul 24, 2008

- Messages

- 20

- Reaction score

- 0

1hand said:Matt;

What are you going to use for X and Y axis steppers? 23's or 34's?

Matt

im going to stick with nema 34's. 400oz for x and y and probably 8-900 oz for z. doing x and y first so I'll try temporarily fitting one of 400oz motors to z when i build it and seeing how much more power it needs to give a reasonable speed. not a massive price difference between 23's and 34's and I'd prefer to have some power in reserve

Matt

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

You can buy flanges for the ball nut but they are more than the ball nut. I made my own single point threading. some builders recommend buying the tap. there is a flat side on the ball nut for a set screw I used it.

I made mounting nuts for my x and y but still have not purchased the ball screws for the mill. . I was going to buy enough for the mill and lathe but now I am doing the litte lathe I can save money I am not going to stuff balll screw into it.

As far as the laptop Go to the mach 3 site you should be able to find out if your laptop will work.

If it does go for it if yours will not work off the shelf you have a choice buy another computer or IMHO a better cheaper choice get a smooth stepper. it is an interface that plugs into a laptop USB port then plug the gecko into the smooth stepper.

Also keep in mind there is a amperage limit (3.5 amps/phase)on the gecko drive make sure your beefy z axis motor does not exceed that limit it may be better to use pulleys and a smaller motor.

Tin

I made mounting nuts for my x and y but still have not purchased the ball screws for the mill. . I was going to buy enough for the mill and lathe but now I am doing the litte lathe I can save money I am not going to stuff balll screw into it.

As far as the laptop Go to the mach 3 site you should be able to find out if your laptop will work.

If it does go for it if yours will not work off the shelf you have a choice buy another computer or IMHO a better cheaper choice get a smooth stepper. it is an interface that plugs into a laptop USB port then plug the gecko into the smooth stepper.

Also keep in mind there is a amperage limit (3.5 amps/phase)on the gecko drive make sure your beefy z axis motor does not exceed that limit it may be better to use pulleys and a smaller motor.

Tin

Tin Falcon said:Also keep in mind there is a amperage limit (3.5 amps/phase)on the gecko drive make sure your beefy z axis motor does not exceed that limit it may be better to use pulleys and a smaller motor.

Tin

Maybe it would just be easier to use a different drive or drivers and stick with the 34's all the way around. A parallel port is a printing port right? So your basic $200 desk top computer would run this right?

1hand said:I've been doing some searching on limit switches and Homing switches, and have opened a whole other can of worms. Are they needed or can you use the soft limits in Mach 3 and still be safe?

Matt

I don't use any type of limit. You are going to get 20 different trains of thought on this one but they can be more of a pain than anything.

1hand said:So what your saying is, I don't "have" to have them to run the machine with Mach 3, and If I'm careful, I shouldn't need them.

That is what i'm saying.

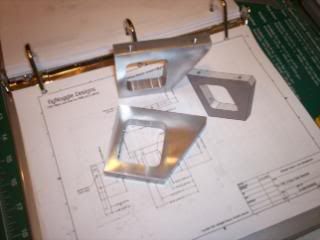

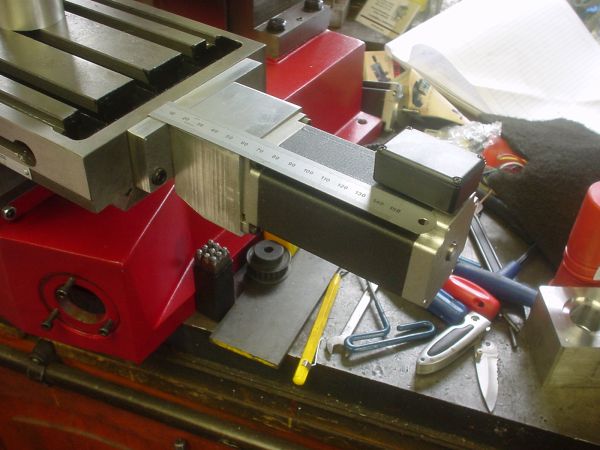

This is what we fit on the X3 and the SX3 on the X and Y, 312 oz in direct driving a 4mm pitch screw.

That square block contains two angular contact bearings and the oldham coupling.

This is the Z mount that bolts onto the existing bottom bearing block, which also has twin angular contacts fitted. the gas strut is thrown away as it's not needed.

Nothing sticks outside the rear cover when fitted.

John S.

That square block contains two angular contact bearings and the oldham coupling.

This is the Z mount that bolts onto the existing bottom bearing block, which also has twin angular contacts fitted. the gas strut is thrown away as it's not needed.

Nothing sticks outside the rear cover when fitted.

John S.

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

any now end new or decent used machine should do the job the requirements are fairly conservative by today's standards . Look at Mach 3 site for requirements.Maybe it would just be easier to use a different drive or drivers and stick with the 34's all the way around. A parallel port is a printing port right? So your basic $200 desk top computer would run this right?

IMHO the easy way to go is the 540. there are other options you can get a breakout board and get individual gecko drive of whatever size you need. I went with the 540 because of ease and value there are cheaper options .

Tin

Similar threads

- Replies

- 38

- Views

- 11K