Now the first of many wiring questions.

This is the nema 23 stepper.

http://www.kelinginc.net/KL23H2100-35-4B.pdf

This the G540 drive.

https://www.geckodrive.com/upload/G540 REV4 MANUAL.pdf

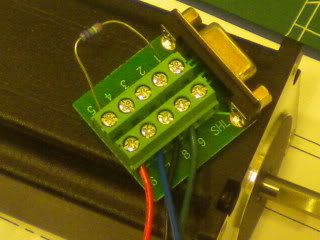

I want to wire up the little db-9 plug in on the motor.

What I gather is this:

I put the 3.48 resistor across from pin 1 and 5.

I hook the RED wire to pin 6

Blue wire to pin 7

Black wire to pin 8

Green wire to pin 9

Am I close?

Matt

This is the nema 23 stepper.

http://www.kelinginc.net/KL23H2100-35-4B.pdf

This the G540 drive.

https://www.geckodrive.com/upload/G540 REV4 MANUAL.pdf

I want to wire up the little db-9 plug in on the motor.

What I gather is this:

I put the 3.48 resistor across from pin 1 and 5.

I hook the RED wire to pin 6

Blue wire to pin 7

Black wire to pin 8

Green wire to pin 9

Am I close?

Matt