- Joined

- May 30, 2011

- Messages

- 135

- Reaction score

- 4

A little random, but it's the break room, wont clog up the important forums.

This might be one of those things that you just have to pay up for, but i might as well try.

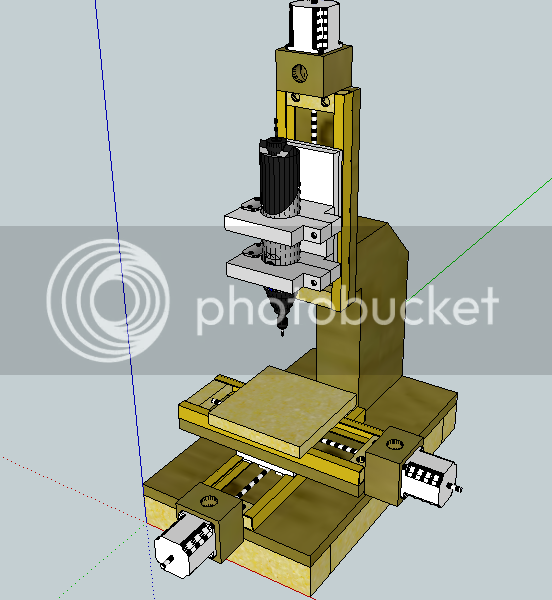

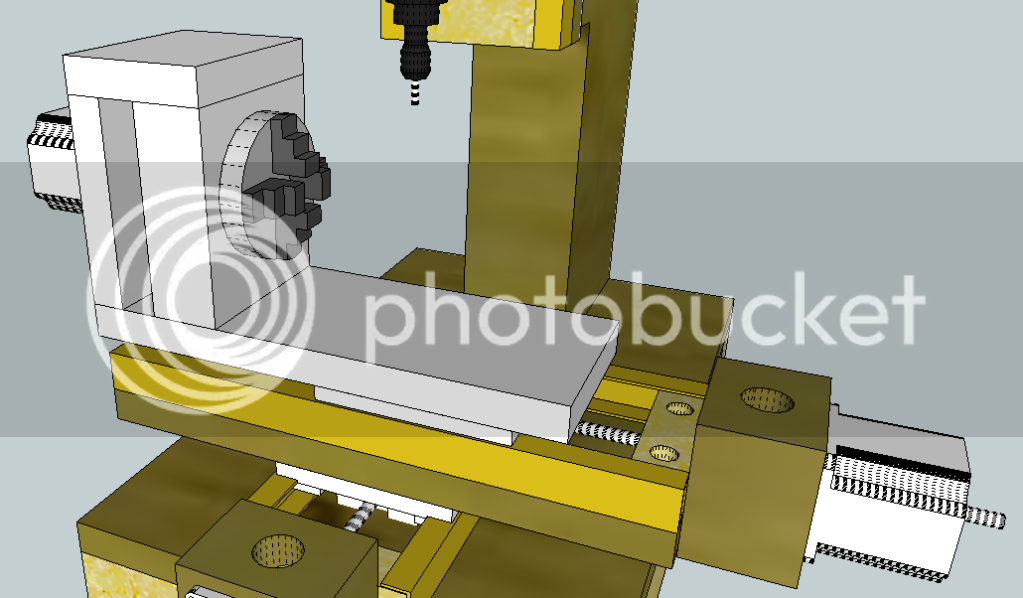

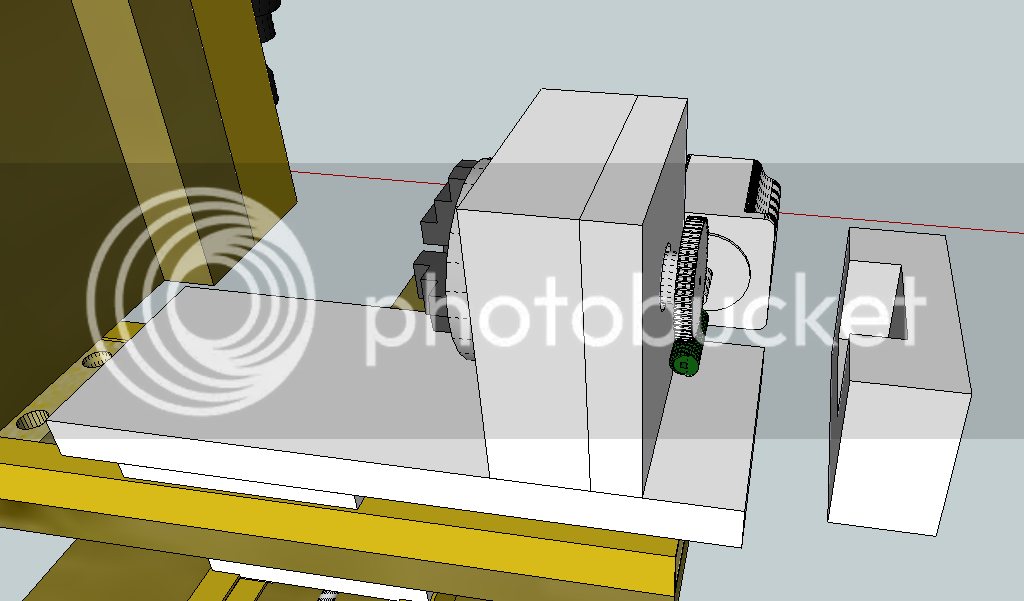

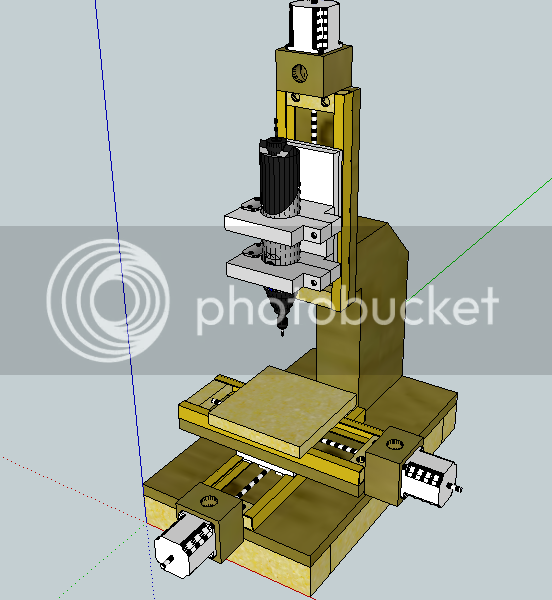

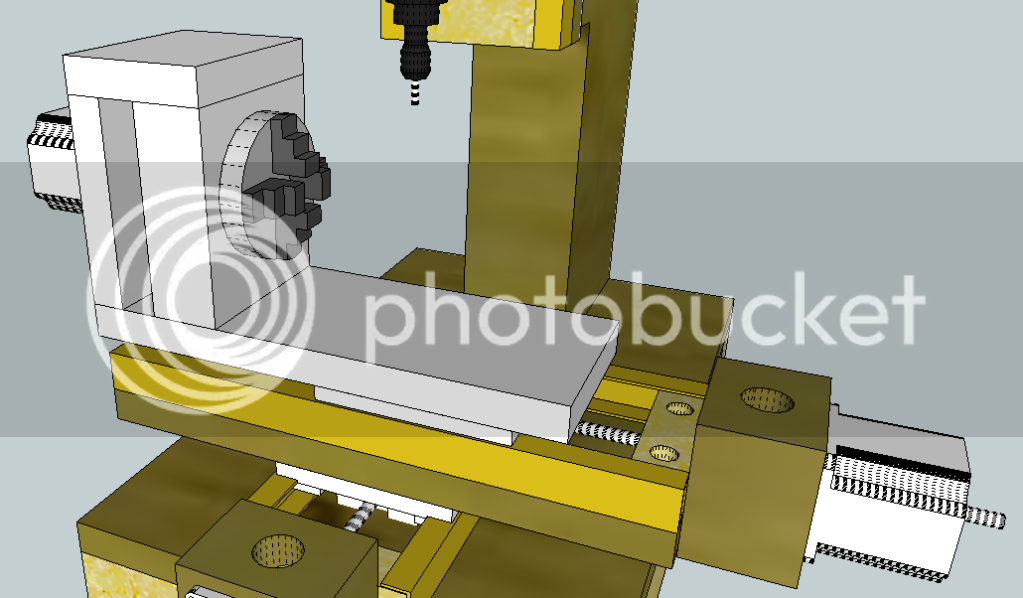

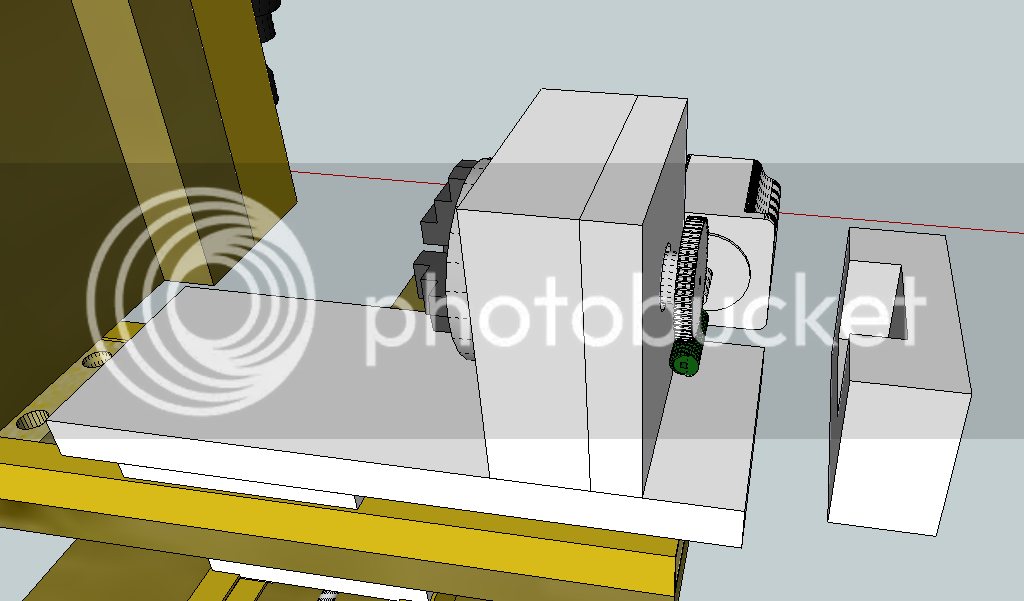

I want to buy a 1" 8TPI DIE so that i can thread some 1" rod. This is to make a new shank for the Grizzly 3" 4-Jaw mini wood lathe chuck. I'm finishing up my home made desktop cnc milling machine, and i have designs for a 4th axis arrangement.

The mill table's cutting area is 6" x 6", so it's a small prototyping 3D wood cutting desktop milling machine. This 3" chuck is perfect to use since it is so tiny and doesn't weight too much.

I have a design set up to use LoveJoy couplers to attach the stepper motor to the chuck, but since arbors are tapered, a regular shaft coupler wont work.

The thread of the arbor going into the back for the chuck is 1"-8. I picked up a length of 6061 Aluminum to use as a new, straight shank (i would say arbor, but since it isn't tapered, i don't think it would be correct to say so).

My stepper motors have 1/4" shanks with NO flats. for the other axis' i have couplers that clamp down onto the shafts by way of compressing the bore of the coupler around onto the shaft. (the side of the bore is cut, like a split washer. and a set screw tightens the bore onto the shaft. The way I'm mounting everything, i wont have access to these set screws, so i need to use lovejoy...

Getting off topic a bit....

So, using the die, i can thread the shank to fit the chuck, and then turn down the other end to any dimension. Seems that the bigger the bore in LoveJoy couplers, the different the Spiders are and the coupling pins; so I guess i could turn it down to 1/4", that, or maybe 3/8".... still figuring that part out...not really a big problem.

The main problem is the Die. they have some on McMaster Carr, but they are $50+... a little too much that i want to pay for.

Enco has HSS Circular for $22 http://www.use-enco.com/CGI/INSRIT?PARTPG=INSRAR2&PMAKA=314-2164&PMPXNO=946625

And a High Carbon Hex for $14 http://www.use-enco.com/CGI/INSRIT?PMAKA=314-5036&PMPXNO=945250&PARTPG=INLMK32

What are your thoughts? Should i go through the hassle of tapping a new shank, or should i pick up an extra arbor and turn it down to not be tapered anymore?

I want to keep the original arbor in good condition so that i can use the chuck on my mini lathe if i need to in the future.

Ian.

ps. i know it might be a little run-on and stuff.

4axis type 1:

4 Axis type 2:

Chuck:

This might be one of those things that you just have to pay up for, but i might as well try.

I want to buy a 1" 8TPI DIE so that i can thread some 1" rod. This is to make a new shank for the Grizzly 3" 4-Jaw mini wood lathe chuck. I'm finishing up my home made desktop cnc milling machine, and i have designs for a 4th axis arrangement.

The mill table's cutting area is 6" x 6", so it's a small prototyping 3D wood cutting desktop milling machine. This 3" chuck is perfect to use since it is so tiny and doesn't weight too much.

I have a design set up to use LoveJoy couplers to attach the stepper motor to the chuck, but since arbors are tapered, a regular shaft coupler wont work.

The thread of the arbor going into the back for the chuck is 1"-8. I picked up a length of 6061 Aluminum to use as a new, straight shank (i would say arbor, but since it isn't tapered, i don't think it would be correct to say so).

My stepper motors have 1/4" shanks with NO flats. for the other axis' i have couplers that clamp down onto the shafts by way of compressing the bore of the coupler around onto the shaft. (the side of the bore is cut, like a split washer. and a set screw tightens the bore onto the shaft. The way I'm mounting everything, i wont have access to these set screws, so i need to use lovejoy...

Getting off topic a bit....

So, using the die, i can thread the shank to fit the chuck, and then turn down the other end to any dimension. Seems that the bigger the bore in LoveJoy couplers, the different the Spiders are and the coupling pins; so I guess i could turn it down to 1/4", that, or maybe 3/8".... still figuring that part out...not really a big problem.

The main problem is the Die. they have some on McMaster Carr, but they are $50+... a little too much that i want to pay for.

Enco has HSS Circular for $22 http://www.use-enco.com/CGI/INSRIT?PARTPG=INSRAR2&PMAKA=314-2164&PMPXNO=946625

And a High Carbon Hex for $14 http://www.use-enco.com/CGI/INSRIT?PMAKA=314-5036&PMPXNO=945250&PARTPG=INLMK32

What are your thoughts? Should i go through the hassle of tapping a new shank, or should i pick up an extra arbor and turn it down to not be tapered anymore?

I want to keep the original arbor in good condition so that i can use the chuck on my mini lathe if i need to in the future.

Ian.

ps. i know it might be a little run-on and stuff.

4axis type 1:

4 Axis type 2:

Chuck: