Tony Bird

Senior Member

Hi,

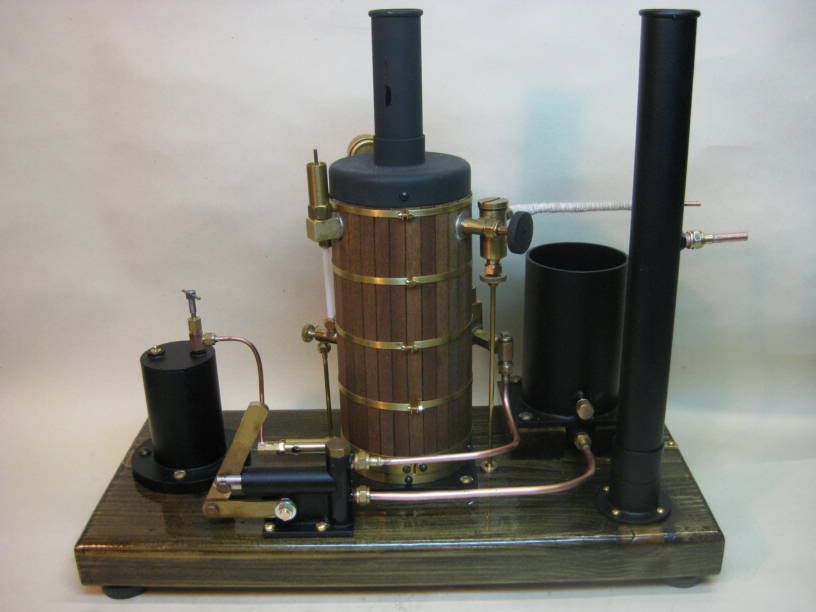

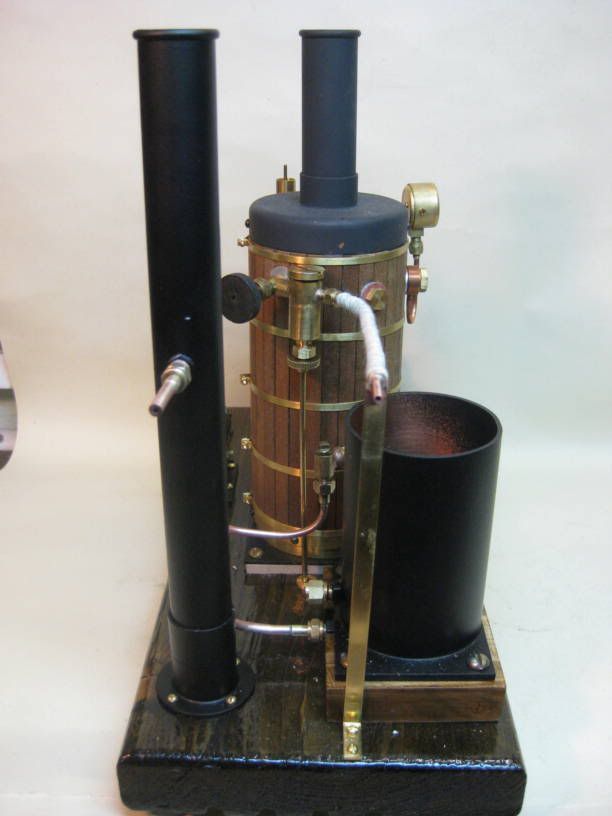

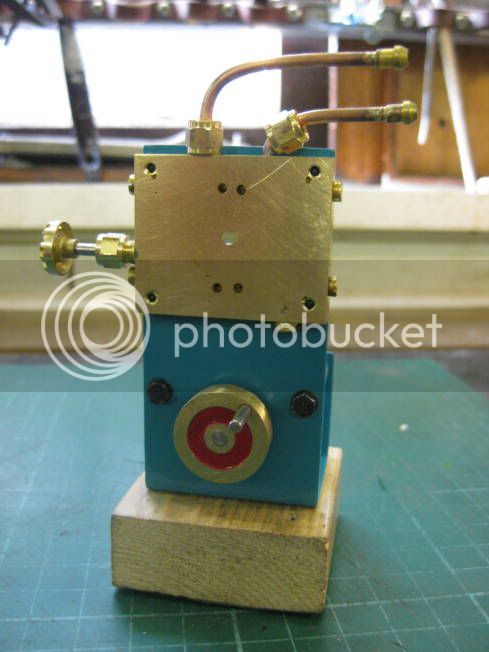

It doesn't matter how many steam engines you have built or how simple they are its is always a thrill the first time you see them run by steam. Compressed air is OK for timing and tweeking them but they are steam engines and I think they look better being run as they are designed for by steam. Today I finished a very simple single cylinder oscillating steam engine with a 8mm bore and 16mm stroke (5/16" x 5/8" in old money). It was built to try something out, which I will now find that someone else has already done.

Most engines that I have built are for use in either steam locomotives or steam boats. This engines was designed as a simple high speed engine for use in a boat. I had noticed that these simple single acting engines start to loose out when the steam pressure is increased due to the cylinder being lifted off the port face. This is not suprising as there is bound to be a point when the steam pressure does this, however double acting engines seem to run better when in this condition than those with single acting cylinders. I think it could be due to the fact that the double acting cylinder is being pushed off the port face at both of its ends so it is being lifted parallel to the port face. Where as the single acting cylinder is being lifted at an angle using the trunnion pin as a fulcrum. If this is so, then it might effect the running of the engine when it isn't receiving too much steam.

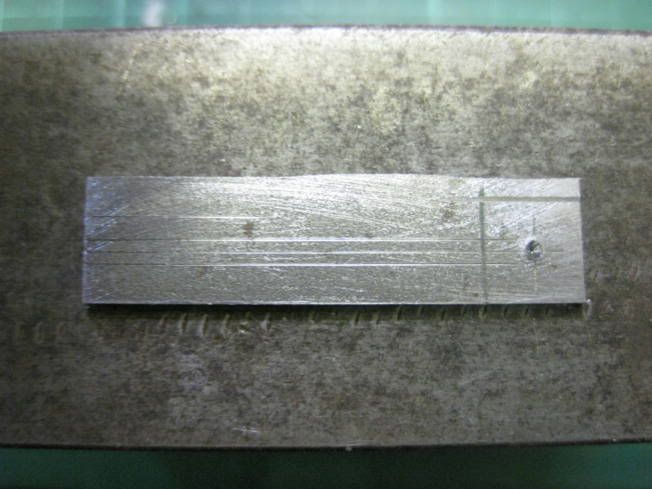

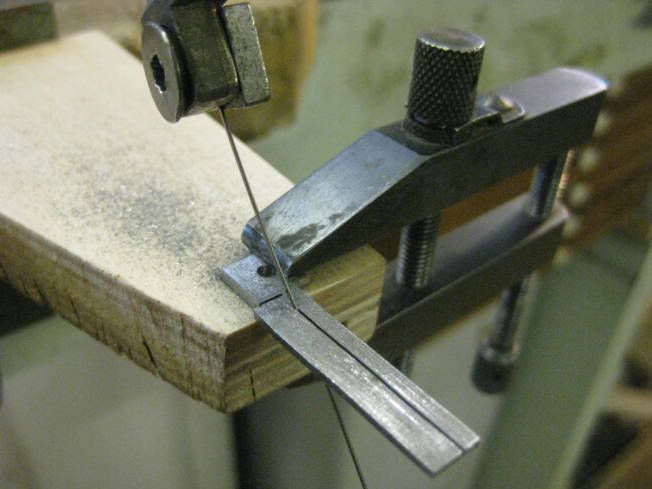

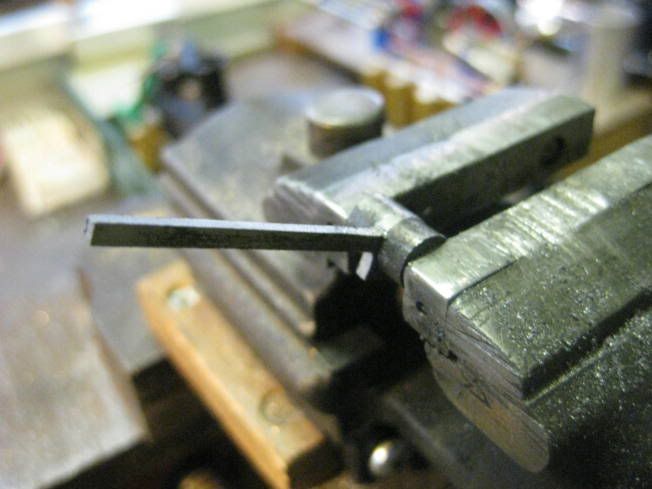

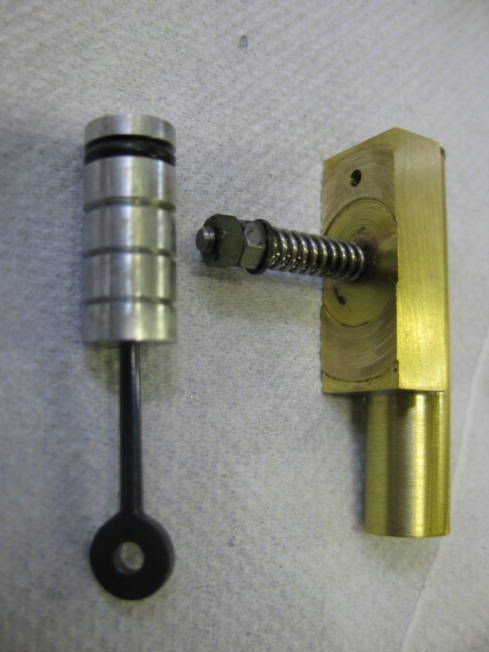

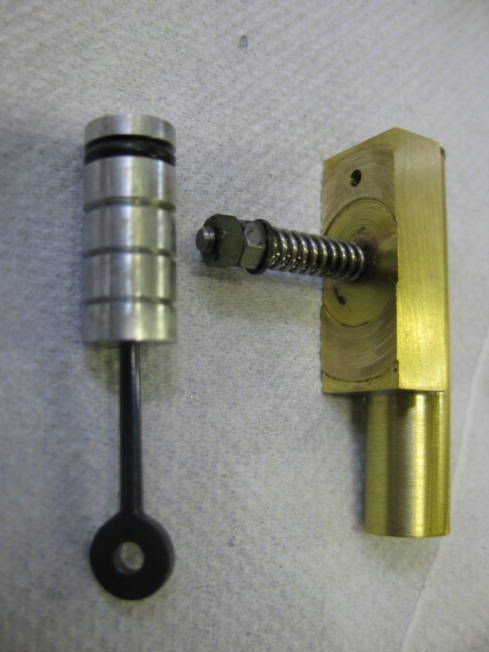

So I have built this engine with a 4 port face of a double acting engine but fitted a single acting cylinder to see if there is an improvement over the standard arrangement of just 2 ports. If nothing else it will lubricate the other end of the cylinder. Later I intend to try try the same arrangement with 2 port block fitted to the same engine. The cylinder and piston are light weight, the cylinder uses a piece of K&S brass tube and the long piston to give a large wearing area, aluminium with an '0' ring and oil grooves.

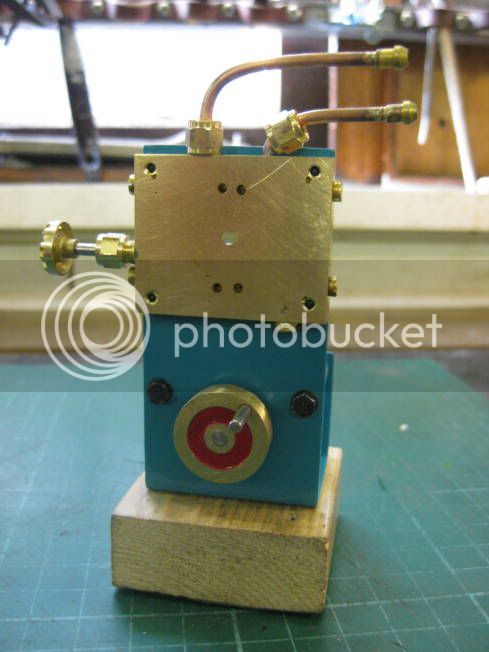

Port face.

Video.

I will have to see after I have made another port face if it was worth the effort with this engine.

Regards Tony.

It doesn't matter how many steam engines you have built or how simple they are its is always a thrill the first time you see them run by steam. Compressed air is OK for timing and tweeking them but they are steam engines and I think they look better being run as they are designed for by steam. Today I finished a very simple single cylinder oscillating steam engine with a 8mm bore and 16mm stroke (5/16" x 5/8" in old money). It was built to try something out, which I will now find that someone else has already done.

Most engines that I have built are for use in either steam locomotives or steam boats. This engines was designed as a simple high speed engine for use in a boat. I had noticed that these simple single acting engines start to loose out when the steam pressure is increased due to the cylinder being lifted off the port face. This is not suprising as there is bound to be a point when the steam pressure does this, however double acting engines seem to run better when in this condition than those with single acting cylinders. I think it could be due to the fact that the double acting cylinder is being pushed off the port face at both of its ends so it is being lifted parallel to the port face. Where as the single acting cylinder is being lifted at an angle using the trunnion pin as a fulcrum. If this is so, then it might effect the running of the engine when it isn't receiving too much steam.

So I have built this engine with a 4 port face of a double acting engine but fitted a single acting cylinder to see if there is an improvement over the standard arrangement of just 2 ports. If nothing else it will lubricate the other end of the cylinder. Later I intend to try try the same arrangement with 2 port block fitted to the same engine. The cylinder and piston are light weight, the cylinder uses a piece of K&S brass tube and the long piston to give a large wearing area, aluminium with an '0' ring and oil grooves.

Port face.

Video.

I will have to see after I have made another port face if it was worth the effort with this engine.

Regards Tony.