You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Something old, Something older---

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

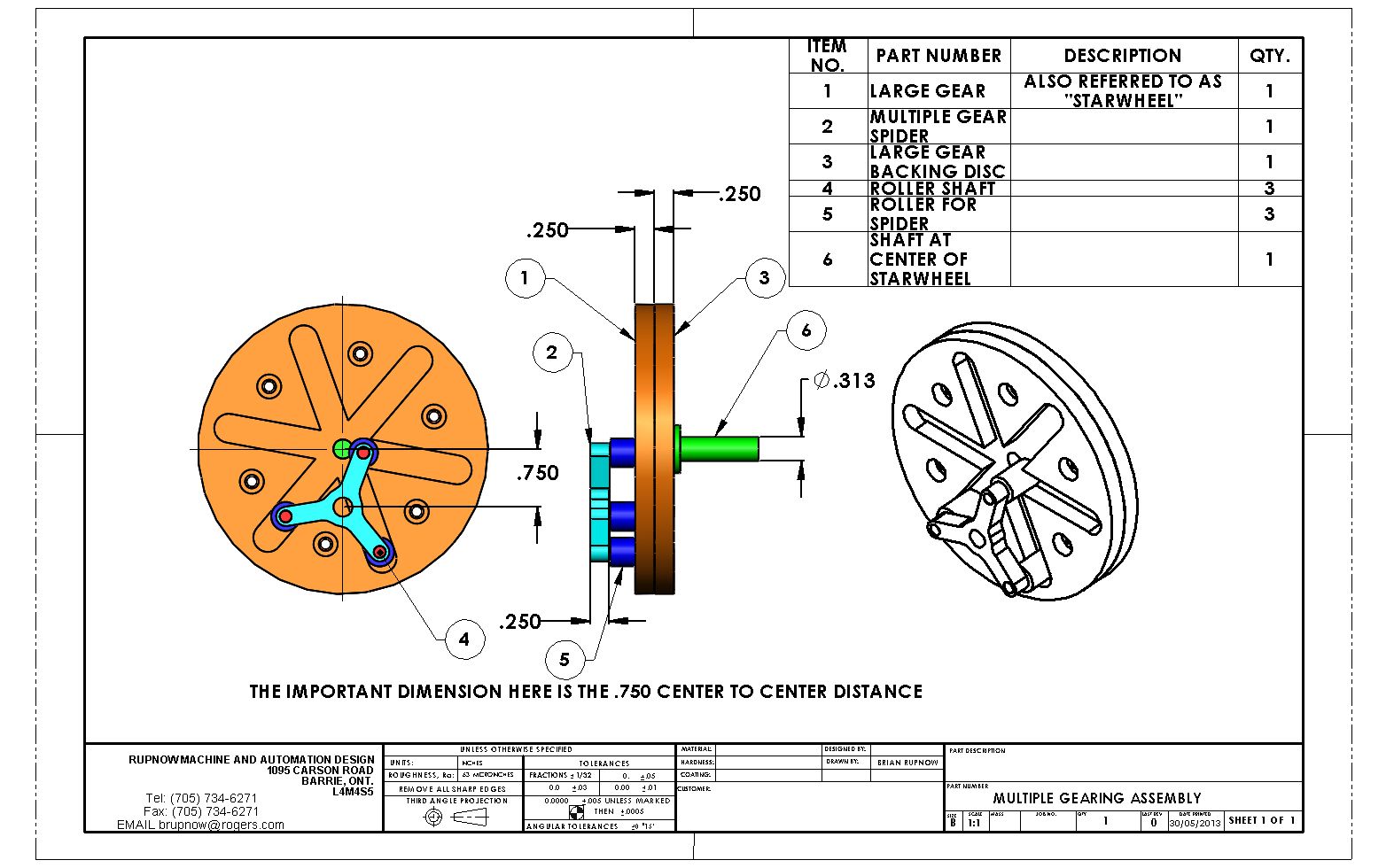

Damn Man!!! Go back and read the whole post. I've given you a verbal description. I've posted pictures. I've posted solid models!!! If you are too lazy or unwilling to read the whole post, then don't bother looking at it.---BrianI gotta say, I'm liking this alot. I'm looking forward to seeing a working model of this!

What are you going to drive with it?

Brian, I haven't studied it a lot as yet but I guess with this type of mechanism, whatever the number of legs are on the spider (with slots to suit), the reduction will always be 2:1 or 1:2 (depending on which one is the input) ?

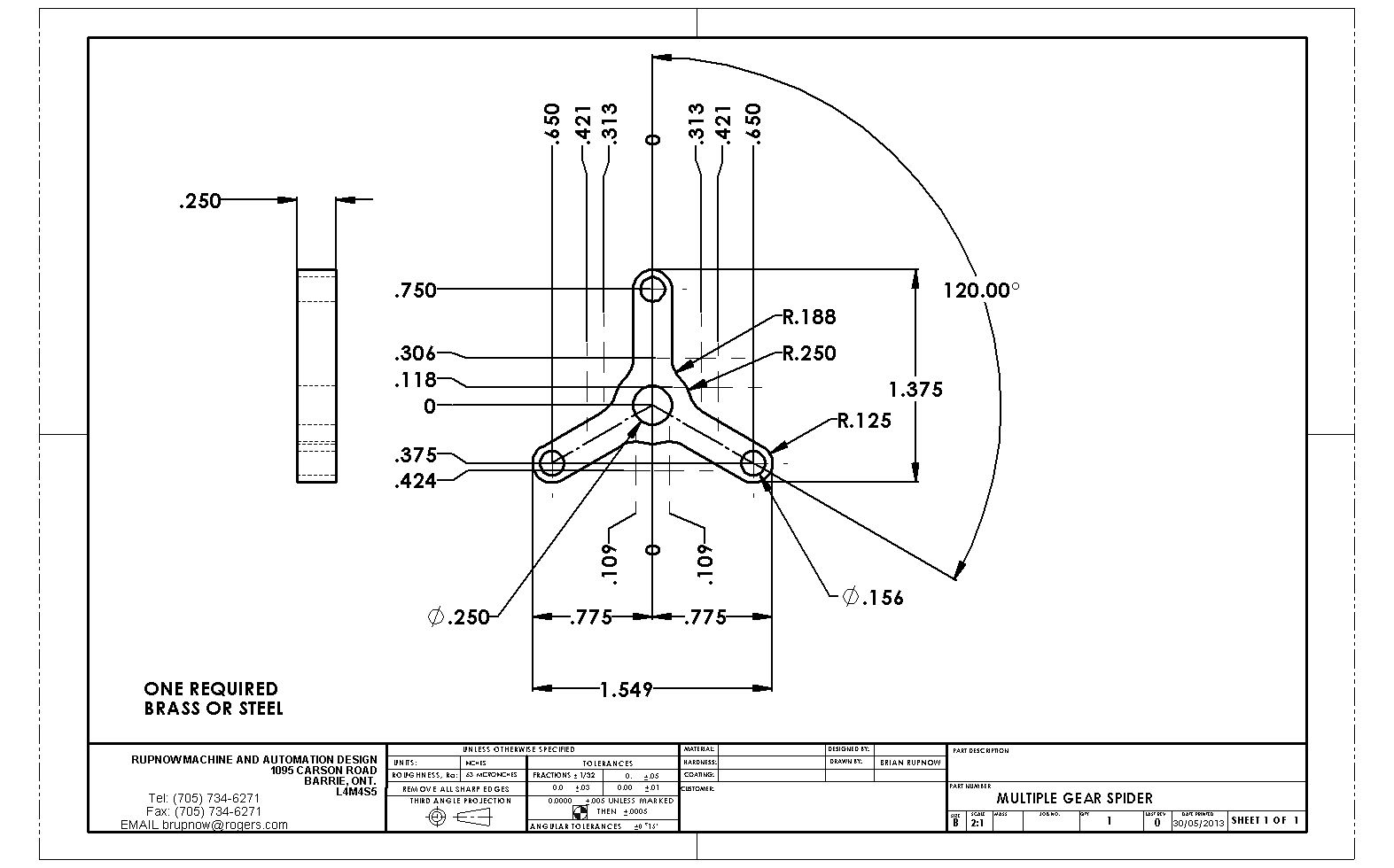

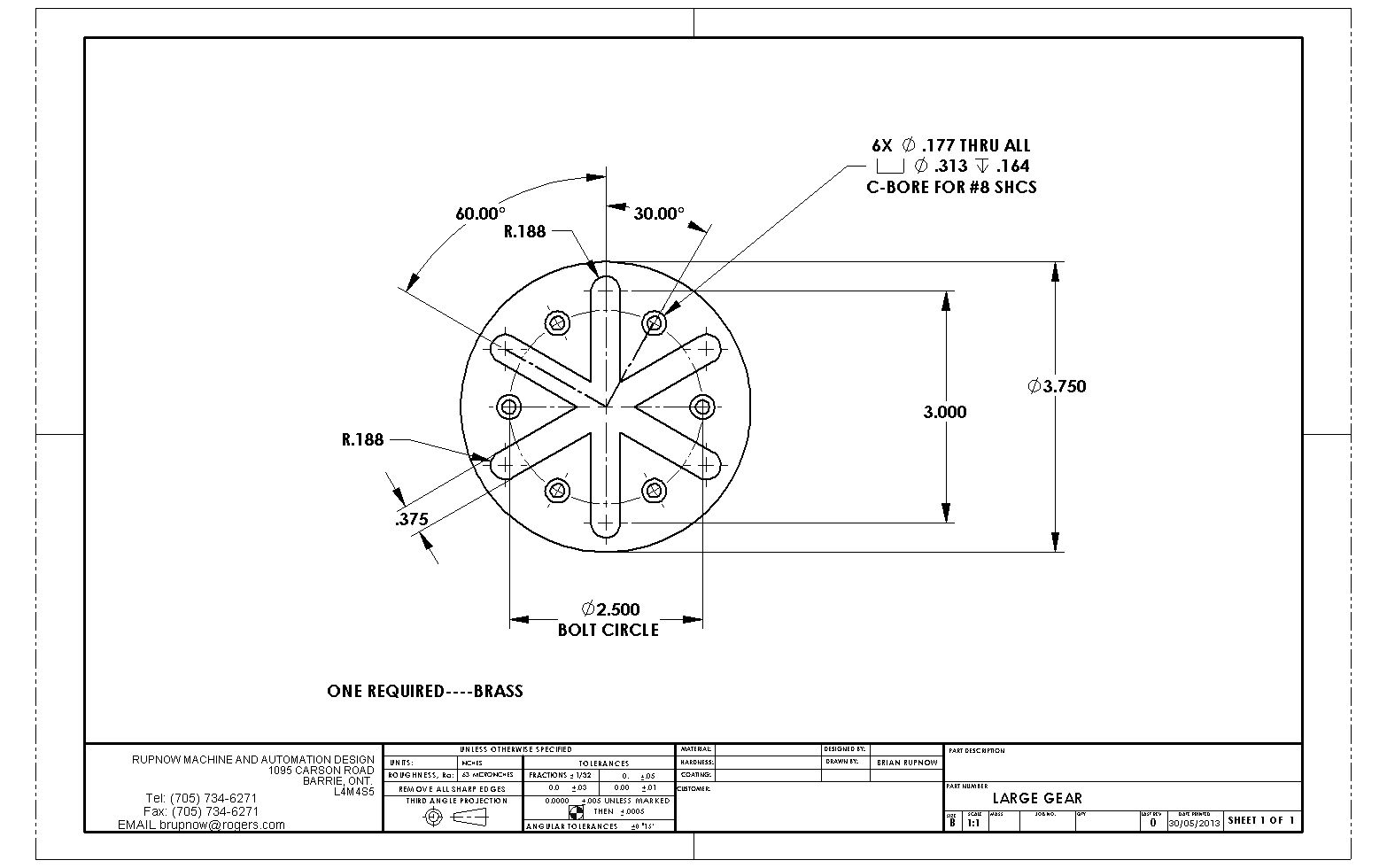

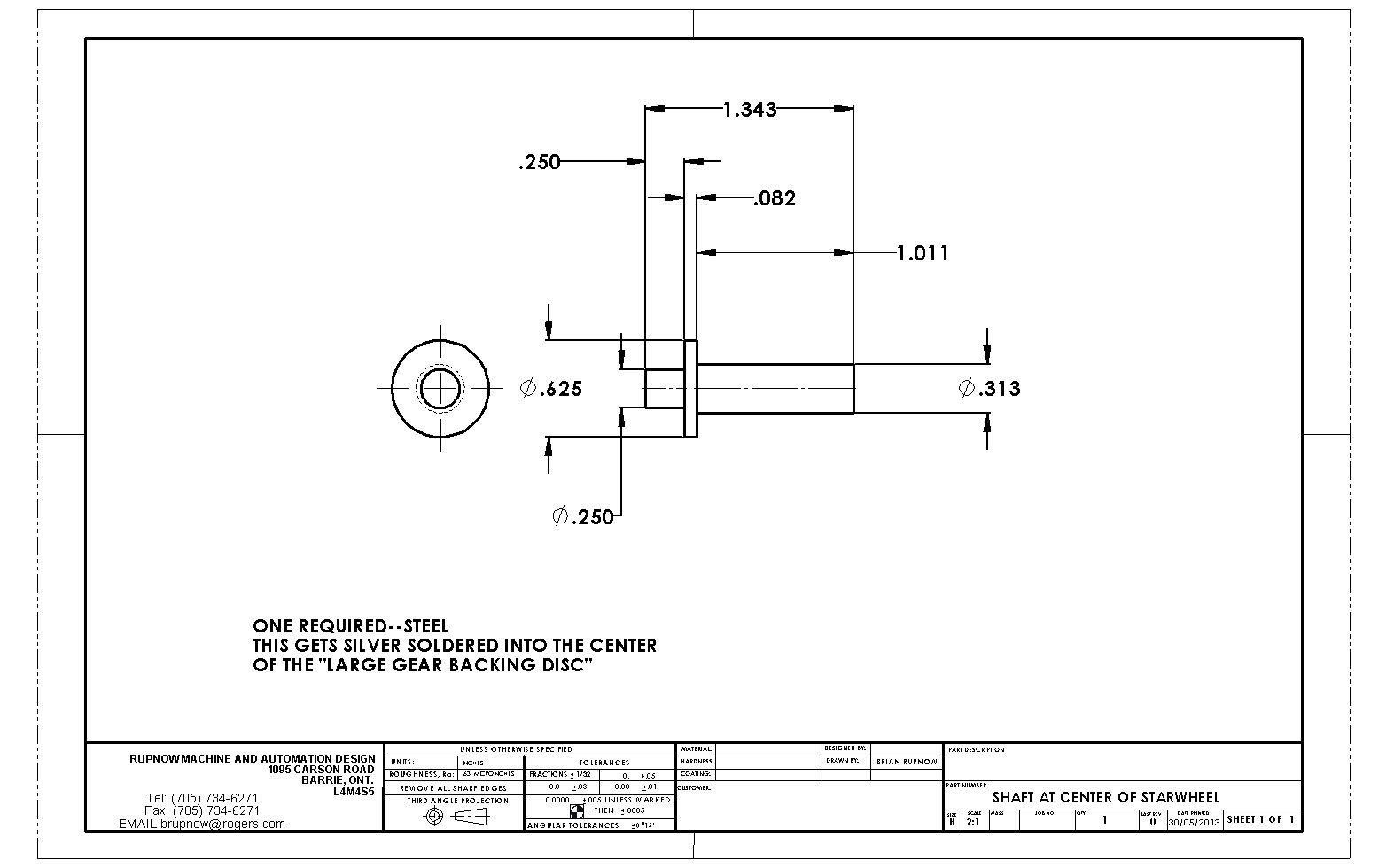

Wildun--I haven't studied on it al that much myself. I know that the radius on the spider is 0.75" and the slots in the starwheel are 3" long. If you look at it in terms of diameters, it is a 2:1 ratio. I don't know if other ratio combinations are possible or not.---Brian

jwcnc1911

-jwcnc191

- Joined

- Mar 19, 2013

- Messages

- 603

- Reaction score

- 86

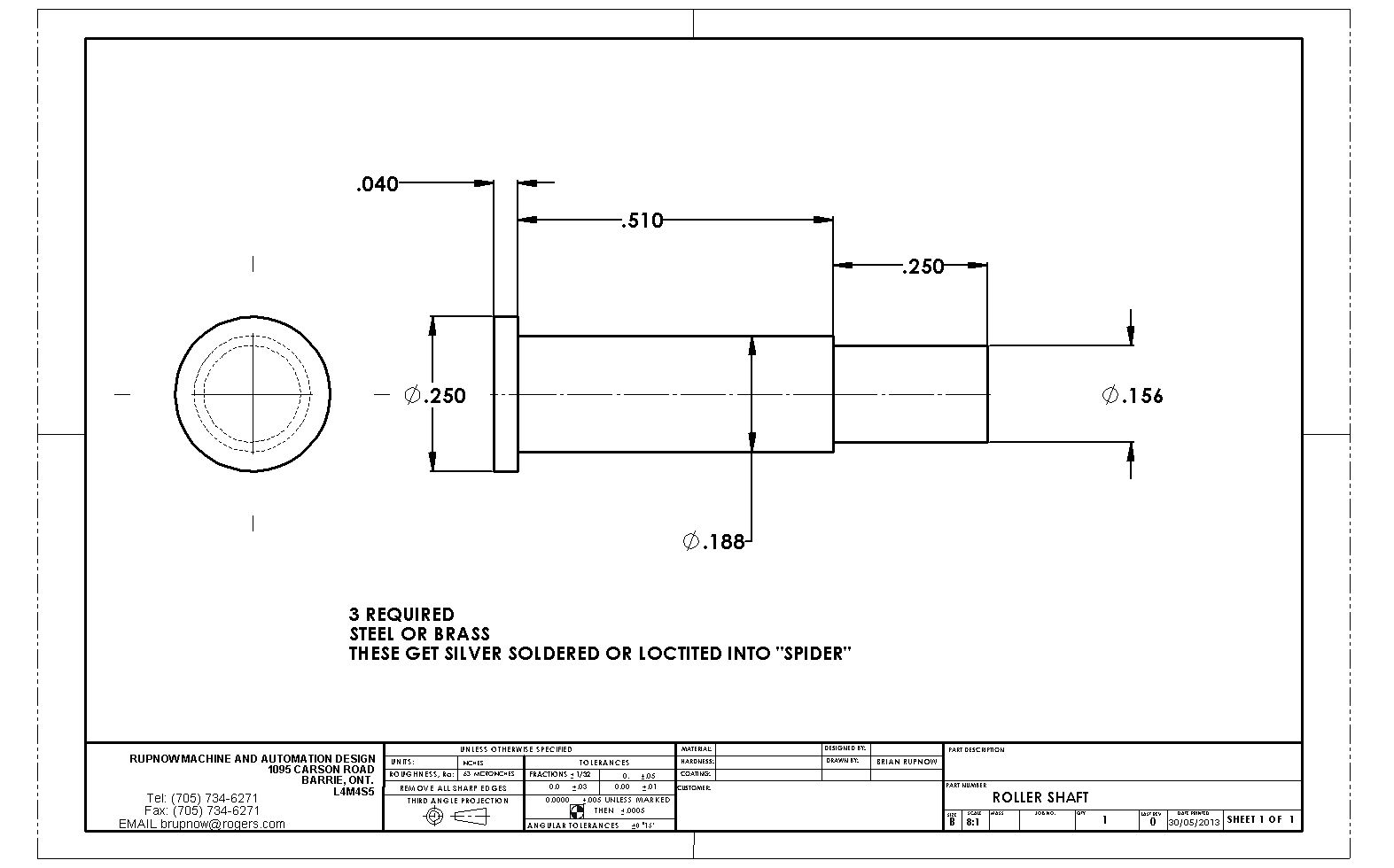

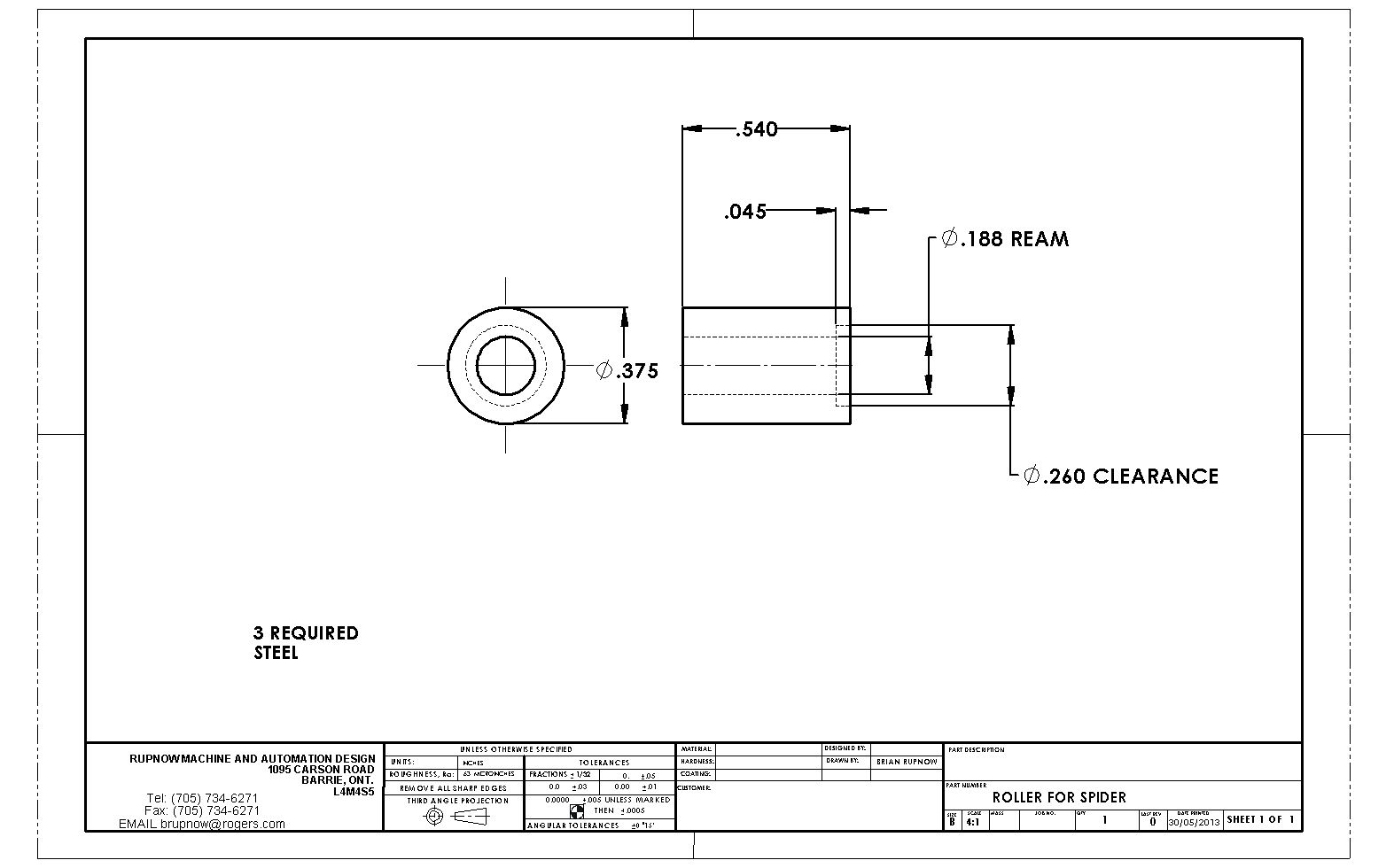

Very nice Brian! Thank you for sharing your drawings.

I have the theory that a 2:1 ratio is optimum. It looks like other ratios will work but... If you go any higher the samller driving gear will not reach as far to the circumference of the driven gear and will result in lower efficiency. Like moving closer to the fulcrum on a lever... you need to be farther away to amplify force.

Fantastic work in making this thing happen though, very skillful! I'm now trying to find an application for this.

I have the theory that a 2:1 ratio is optimum. It looks like other ratios will work but... If you go any higher the samller driving gear will not reach as far to the circumference of the driven gear and will result in lower efficiency. Like moving closer to the fulcrum on a lever... you need to be farther away to amplify force.

Fantastic work in making this thing happen though, very skillful! I'm now trying to find an application for this.

Brian,If you look at it in terms of diameters, it is a 2:1 ratio.Brian

I got that idea from watching the animation, - if you watch one of the legs on the spider carefully, it will move from one end of a slot to the other end of that slot (in one revolution) so that means the large wheel (slotwheel?) will have turned thru 180deg. So, 2 revs of the spider = 1 rev of the slotwheel and as far as I can see the case would be the same with with a two legged "spider" (if that's possible

Anyway, you seem to have done a sterling job!

jwcnc1911

-jwcnc191

- Joined

- Mar 19, 2013

- Messages

- 603

- Reaction score

- 86

Brian,

I got that idea from watching the animation, - if you watch one of the legs on the spider carefully, it will move from one end of a slot to the other end of that slot (in one revolution) so that means the large wheel (slotwheel?) will have turned thru 180deg. So, 2 revs of the spider = 1 rev of the slotwheel and as far as I can see the case would be the same with with a two legged "spider" (if that's possible), but I need to add that I could be wrong!

Anyway, you seem to have done a sterling job!

The ratio would still be diametral, like a gear with more or less theeth, the pitch only changes.

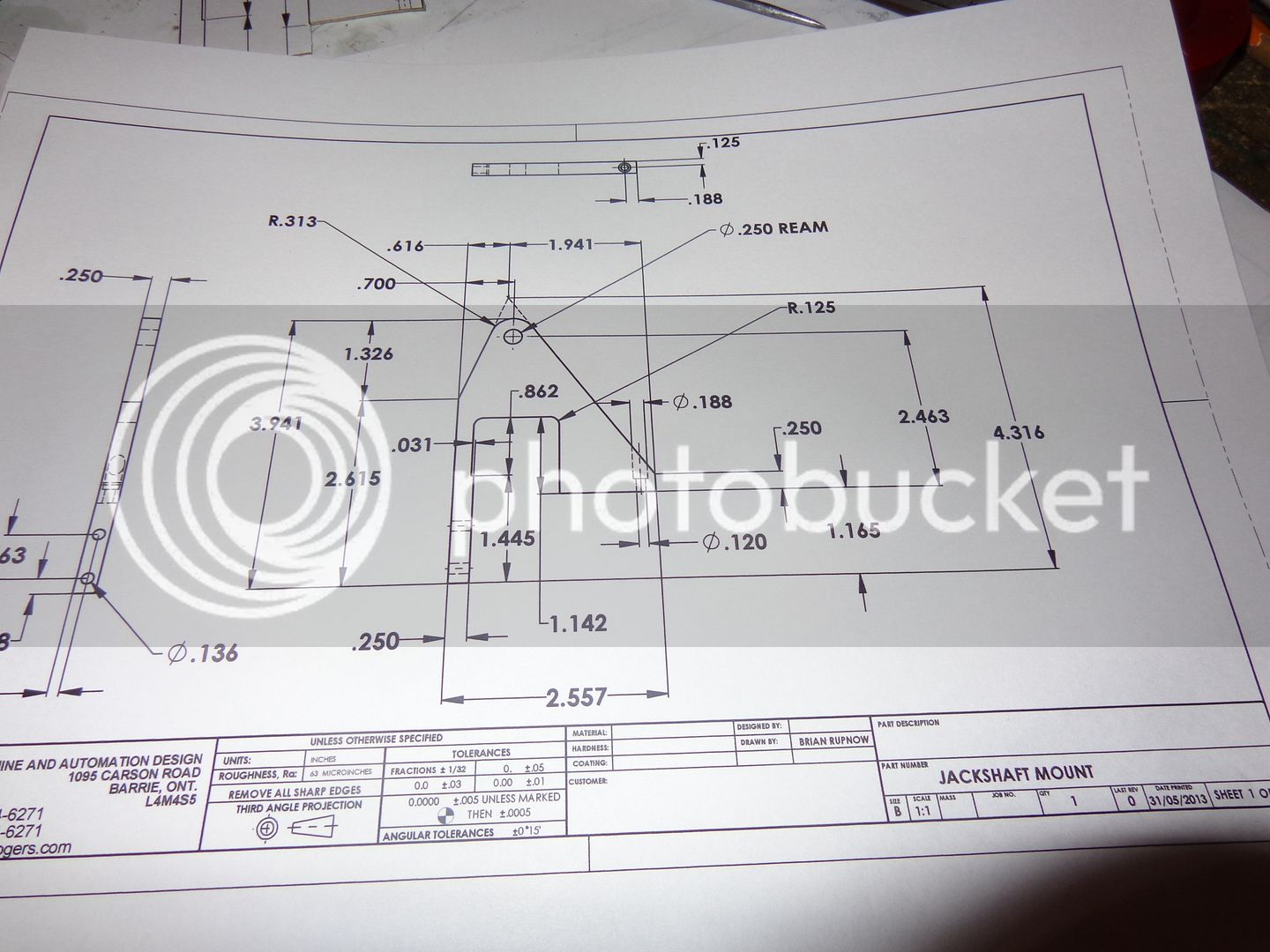

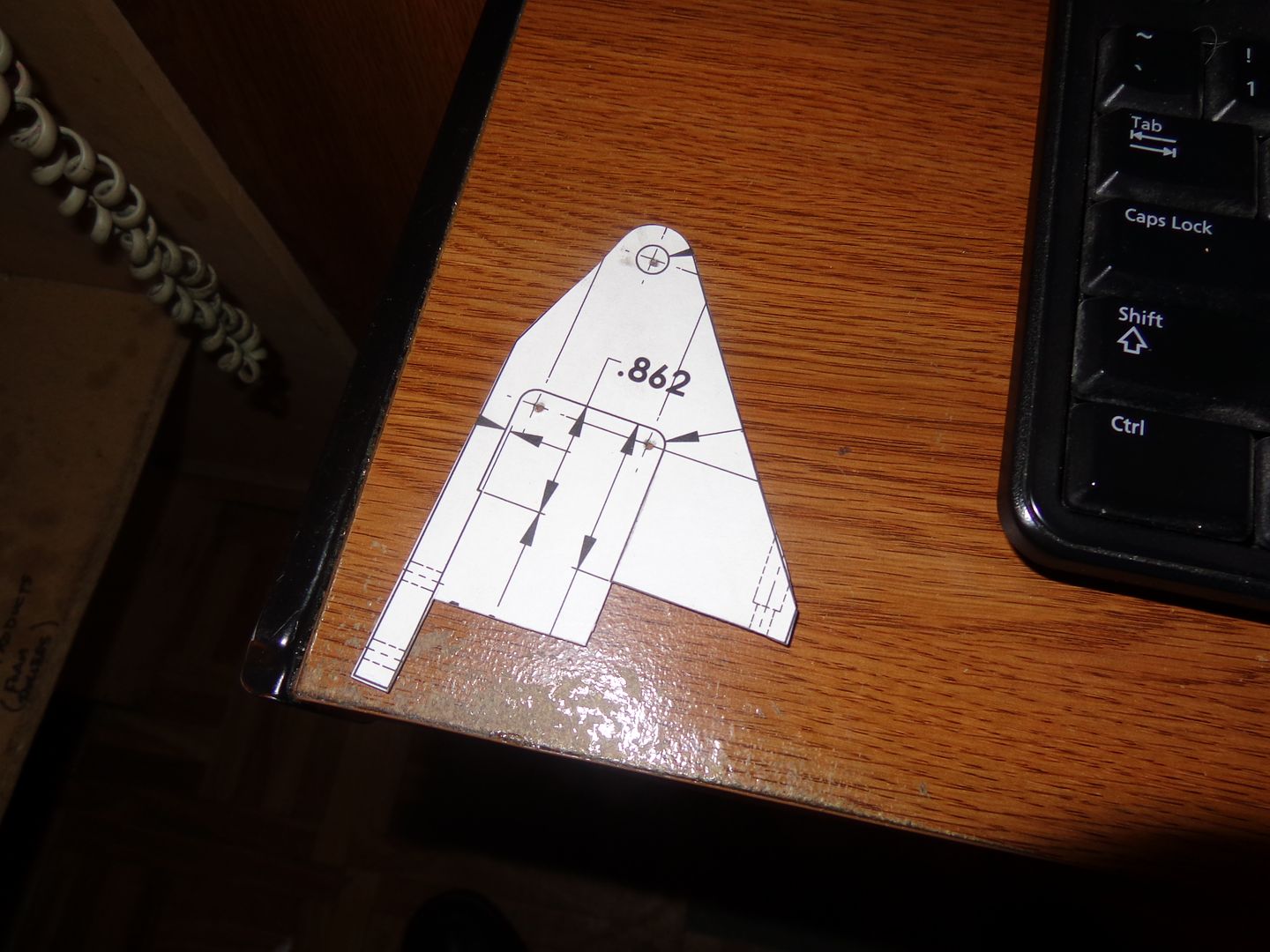

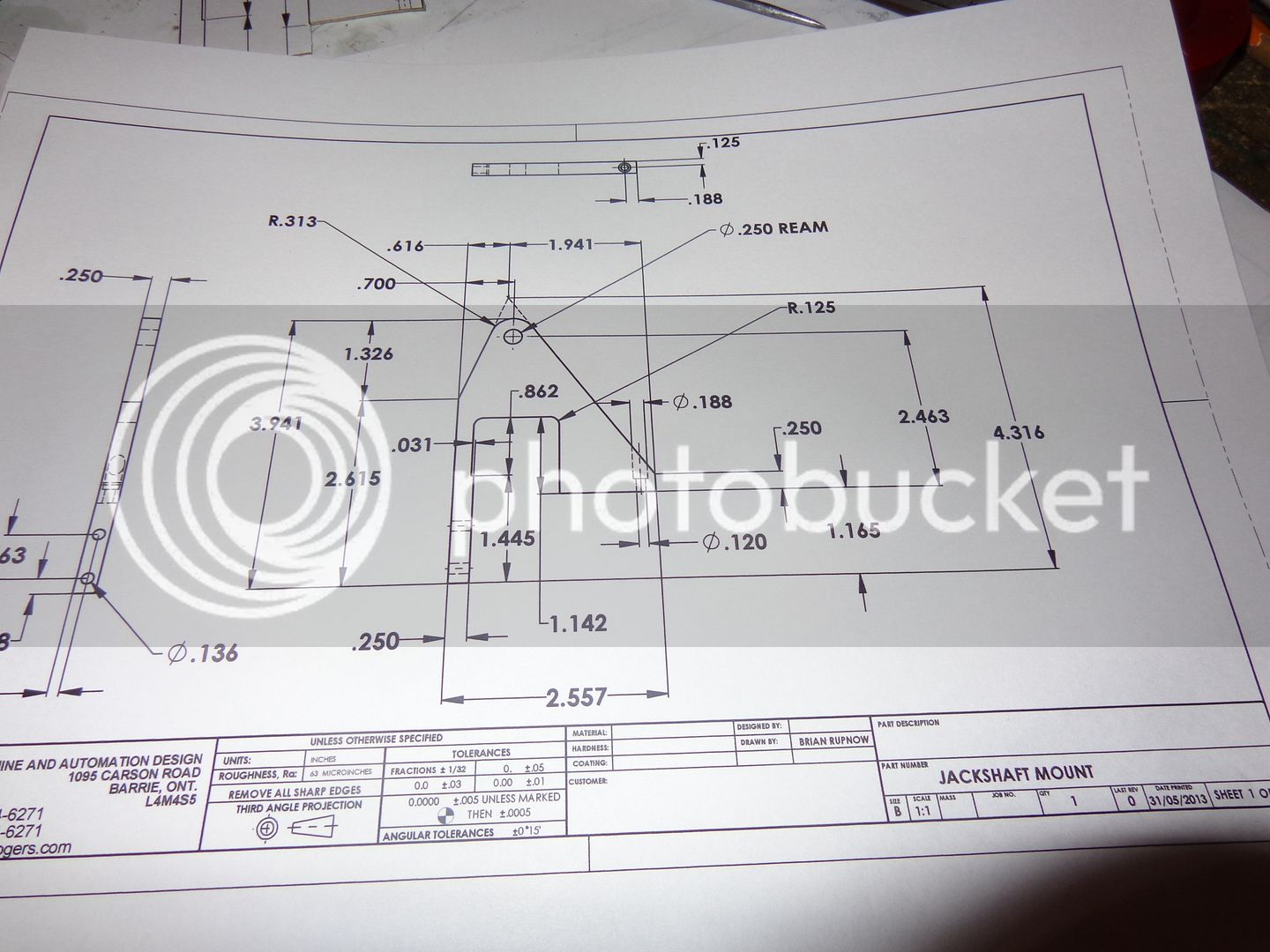

I don't expect anyone to make the following part. It will work only with the particular engine that I am using. This is really more about "method". First I draw and dimension the part. Then I print it out at one ne scale and cut it out, then glue it to a piece of cereal box cardboard. I line up one of the non critical edges with an edge on the material which I intend to cut it from, which has been coated with layout dye and trace around the edges with my scriber. Anywhere that there is an internal radius, I use a centerpunch to punch thru the cardboard template and leave a center punch mark in the metal. Then its a trip to my vertical bandsaw, to cut the pieces out, and over to my mill drill to drill out holes at the "punch" marks. On any critical mating surfaces, I leave about .030" of material to be milled off. Anywhere that it is just a "cosmetic" surface which doesn't mate with anything, I carefully "cut to the line" with my bandsaw, and will finish those areas with a hand file..

ne scale and cut it out, then glue it to a piece of cereal box cardboard. I line up one of the non critical edges with an edge on the material which I intend to cut it from, which has been coated with layout dye and trace around the edges with my scriber. Anywhere that there is an internal radius, I use a centerpunch to punch thru the cardboard template and leave a center punch mark in the metal. Then its a trip to my vertical bandsaw, to cut the pieces out, and over to my mill drill to drill out holes at the "punch" marks. On any critical mating surfaces, I leave about .030" of material to be milled off. Anywhere that it is just a "cosmetic" surface which doesn't mate with anything, I carefully "cut to the line" with my bandsaw, and will finish those areas with a hand file..

The ratio would still be diametral, like a gear with more or less theeth, the pitch only changes.

Always the same ratio (2:1) - I'll accept it if you prove me wrong!

I wonder if the "surface speed" of the outer diameter of the driven wheel will maintain constant as it goes a complete revolution. I would think that there will be slight "speed ups" and "slows down" as the rollers travel along the different angle positions on the slots. It should be interesting to watch in slow motion.

jwcnc1911

-jwcnc191

- Joined

- Mar 19, 2013

- Messages

- 603

- Reaction score

- 86

I wonder if the "surface speed" of the outer diameter of the driven wheel will maintain constant as it goes a complete revolution. I would think that there will be slight "speed ups" and "slows down" as the rollers travel along the different angle positions on the slots. It should be interesting to watch in slow motion.

Angular speed will be the same. "surface speed" or surface footage will be diametrically relative... Larger the diameter, the higher the surface footage.

I don't think so. If you look at the typical crossed universal joint, when it's at an angle, it accelerates and decelerates twice in each revolution.Angular speed will be the same. "surface speed" or surface footage will be diametrically relative... Larger the diameter, the higher the surface footage.

Yes--Send me your "real" email address on the "private message" function and I will send you a download link to the solids models.---BrianBrain... would you be willing to send me your solids to save me a little time playing with this?

If someone can explain how, I will upload the file to the HMEM site and then anybody interested can download the solid models and drawings. I have them zipped up and they are only 1.8 Megs.

Similar threads

- Replies

- 7

- Views

- 2K

Latest posts

-

For Sale Murdoch & Aitkin Steeple Steam Engine

- Latest: hopperwhistle

-

For Sale Full Scale Creators Popcorn Steam Engine Kit

- Latest: hopperwhistle

-

For Sale Home Shop Machinist Maverick Gas Engine Project

- Latest: hopperwhistle

-

-

-

-

-

-