HI guys. I'm in the market for a small milling machine. Have been looking at the SX2, X2, and Taig. Sherline looks a little too small. By the time you get an X2 set up and a belt drive on it, you can get an SX2 that already has a belt drive and a larger motor.

I checked out a few sites about the Taig and am kinda leaning towards one of those. Right now you can get one on sale with a vise, small set of collets, a couple of end mills and free shipping. Probably not much of a vise, but would probably work until i bought or made one. Cost would be about the same as a micro-mark with shipping, maybe a few bucks cheaper. I have a larger milling machine, so work envelope is not a problem. I want a smaller one so i don't keep eating small tooling. Feel on my machine is not the greatest for little tools.

Now, i have looked for a manual for the Taig and havn't been able to find one. So, have some questions. It looks like the z travel is controlled by a handwheel on top of the machine. Is that correct? Is that the only Z control you have?? If so, how is drilling holes with one of these guys??

How much distance per revolution is there on the x, y and z? What are the graduations?? .001?

How much tune up is needed out of the box?? I have a couple of Chinese machines, and there is quite a bit of tuning to do before you cut metal.

Is it worth the money to get the larger motor option? I Have no plans to cnc, so it will just see manual use.

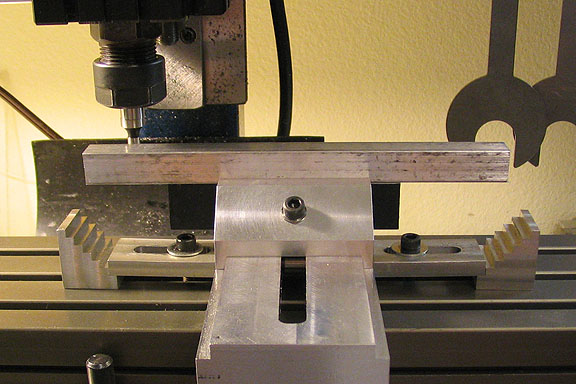

The tooling plate looks interesting. Does anyone have one that can comment on those?

Appreciate any help here fellas. Noplace around here i can go put my hands on one and check it out. Thanks. Regards, j.d.

I checked out a few sites about the Taig and am kinda leaning towards one of those. Right now you can get one on sale with a vise, small set of collets, a couple of end mills and free shipping. Probably not much of a vise, but would probably work until i bought or made one. Cost would be about the same as a micro-mark with shipping, maybe a few bucks cheaper. I have a larger milling machine, so work envelope is not a problem. I want a smaller one so i don't keep eating small tooling. Feel on my machine is not the greatest for little tools.

Now, i have looked for a manual for the Taig and havn't been able to find one. So, have some questions. It looks like the z travel is controlled by a handwheel on top of the machine. Is that correct? Is that the only Z control you have?? If so, how is drilling holes with one of these guys??

How much distance per revolution is there on the x, y and z? What are the graduations?? .001?

How much tune up is needed out of the box?? I have a couple of Chinese machines, and there is quite a bit of tuning to do before you cut metal.

Is it worth the money to get the larger motor option? I Have no plans to cnc, so it will just see manual use.

The tooling plate looks interesting. Does anyone have one that can comment on those?

Appreciate any help here fellas. Noplace around here i can go put my hands on one and check it out. Thanks. Regards, j.d.