- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

Her's a little tool for you to asymalate

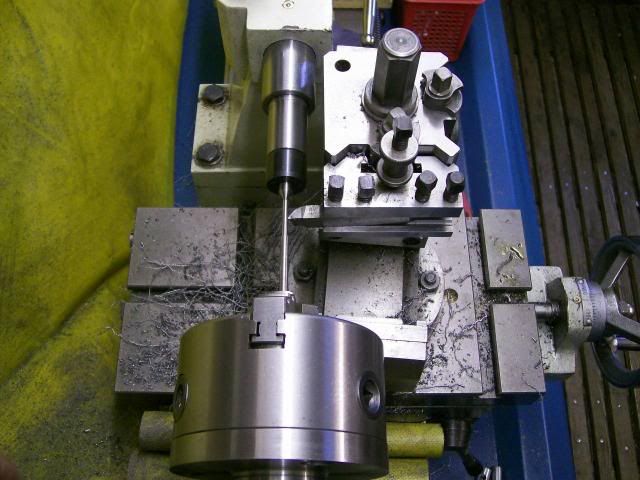

My machine has a M3 morse taper in the tail stock, the running centres you get for this size all seem to be big brutes far too big for the size of work I do, and it not always easy to get in, with a nice robust set up.

So these are the bits I picked up from the Harrogate show: from the Arc Euro trade stand

The arbour was set up in the head stock held nice a secure with a draw bar, faced off and turned down to match the centre:- it was made of some quite tuff stuff.

Then it was centre drilled and with a couple of pilot drills opened out to 9mm by 25mm deep.

Then with a nice little boring bar bored out to 10mm for a nice fit on the centre

Then it was secured with good old high strength loctite:- her it is with its big brother

And how it will look in use

Job done in about 2 hours but it will be a big help in the future

:nrocks:

:nrocks:

Stew

My machine has a M3 morse taper in the tail stock, the running centres you get for this size all seem to be big brutes far too big for the size of work I do, and it not always easy to get in, with a nice robust set up.

So these are the bits I picked up from the Harrogate show: from the Arc Euro trade stand

The arbour was set up in the head stock held nice a secure with a draw bar, faced off and turned down to match the centre:- it was made of some quite tuff stuff.

Then it was centre drilled and with a couple of pilot drills opened out to 9mm by 25mm deep.

Then with a nice little boring bar bored out to 10mm for a nice fit on the centre

Then it was secured with good old high strength loctite:- her it is with its big brother

And how it will look in use

Job done in about 2 hours but it will be a big help in the future

Stew