Ron

Thanks

I pondered over what lathe to buy, but in NZ there isn't a huge choice of this type of lathe. I couldn't get much by way of reviews either, apart from a couple of Ozzies on HMEM with Hafco's. Once I'd bought it I then found that there are a lot of people out there with a lathe from this range, re-branded by the importer , Hafco, Crusader, Grizzley and no doubt many others. When I found John Bogstandard has the same model I knew there were to be no more excuses.

Arnold

Thanks

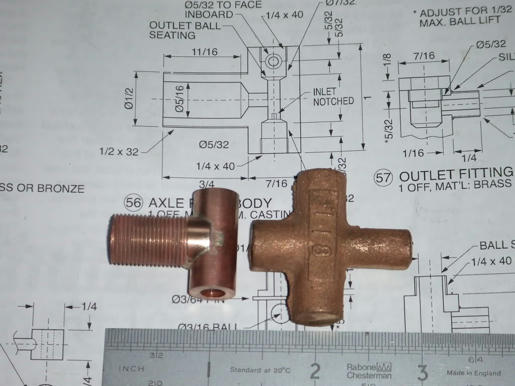

The same thought crossed my mind, but I've built it to the drawings. I also checked the Rob Roy drawings and that's 90deg as well. I'm pressing on, its a long weekend coming up so may just start on the castings.

Blighty

Thanks

I had all those problems and had to work on getting it right, solder, flux, torches, gas, hearth and technique. (no welding involved)

This is my biggest torch 85Kw. I haven't used it this way but I understand 'normal practice' is to have a helper on the big torch keeping the job hot and then use a small torch to heat locally. I've no idea how that works with this flame thrower going. It can get very hot just holding it

Take a look at my other boiler threads to see how well they went, or not. That's why I did this boiler to learn more. Even teh technique of holding the torch at the right distance from the job was realised recently. That big torch is way hotter when 18" from the job than closer in.

Pete