Thanks Pete, it's getting there

_________________________________________________

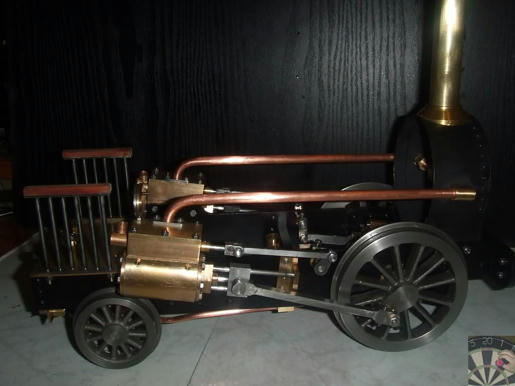

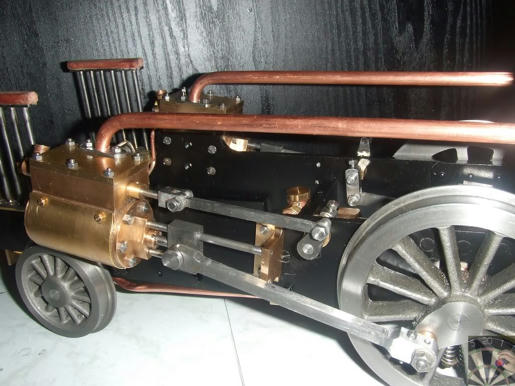

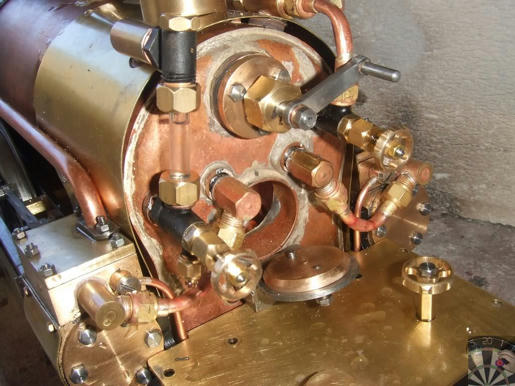

There were just a few more bits of pipework to do to complete the super-heater header and the connecting pipes to the steam chests. They took ages to get all lined up. I'd suggest that the way the drawings have the lubricator connection inboard of the steam pipes needs to be reconsidered. I've already suggested that the the connections need to be moved, but now I'd also suggest that the lubricator unions need to be outboard of the steam pipe elbow. They just get in the way otherwise. I had no choice so had to remake the elbows longer so it would all go together.

Anyway I got it done in the end and also added all the other fittings.

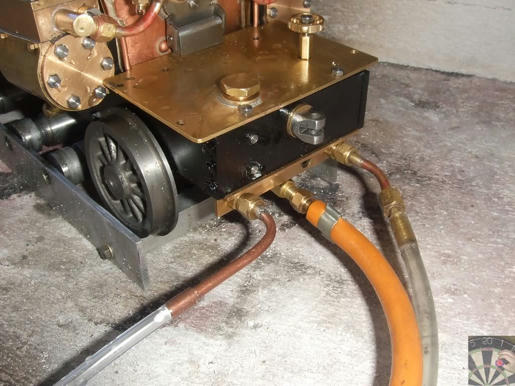

So the time had come to connect it all up and see what happens

Water input and return feeds and gas pipe.

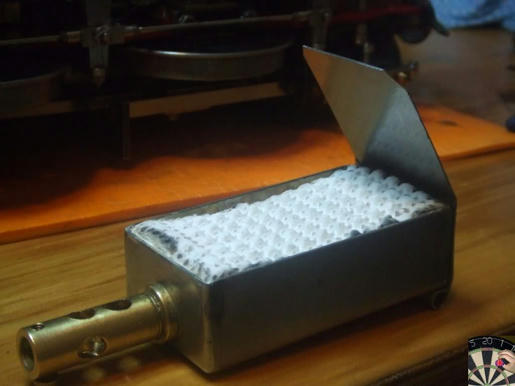

My 'micro blower' made from a computer fan. Its made this way in an attempt to stop steam going directly through the fan,

And of course light it up.

To be honest it took some work to get it going and as the boiler isn't certified (its done the pressure test) the plan was to keep the pressure below 30psi (working pressure is 80psi)

[ame]http://www.youtube.com/watch?v=5PBPEbrN-qY[/ame]

There's a bit of a knock in there somewhere and the burner needs a bit of work to get it to burn better, but its a start. Time for a complete strip down finishing, lagging, cladding, painting etc

Pete