Tony Bird

Senior Member

Hi Gus,

Sorry I cannot help withyour glow plug problems.

Please advise silver solder rod content. I use higher silver content for ease of brazing. Air conditioners' silver solder rod can be tough to melt and run. Plan to buy a double torch Mapp Gas Torch after watching demo.

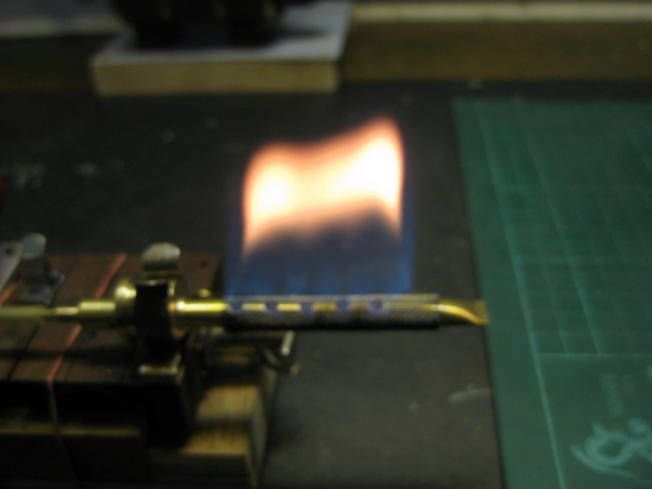

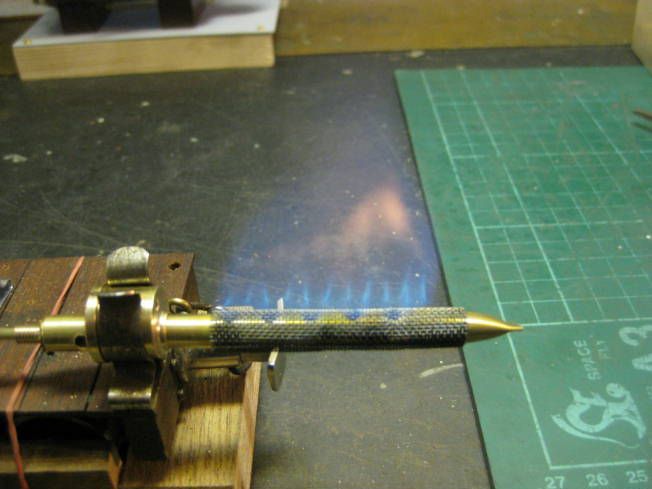

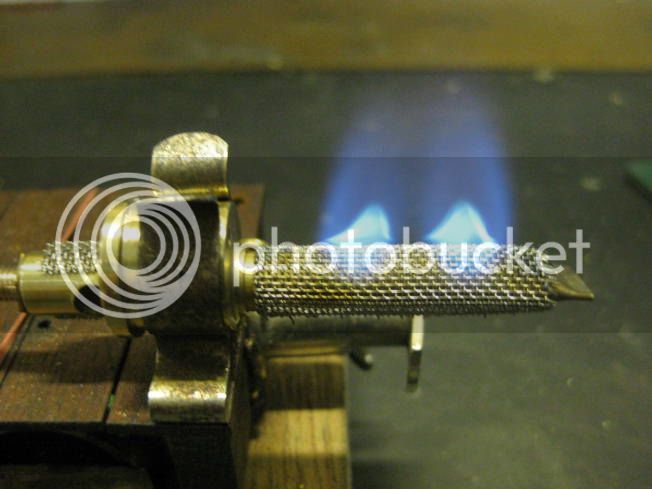

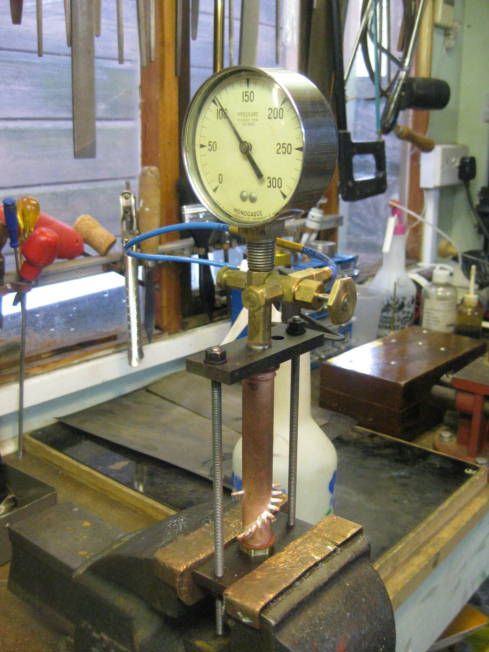

At the moment I am using Easyflo No.2 silver solder and flux which melts at about 640C. Sorry I don't know how this compares with solders used in the USA. The pickle I use is Citric acid which I get from Home Brew/Wine stores. The powder is mixed in hot water until the mix is saturated. I.e. when crystals that won't desolve appear in the mix. I use a plumbers gas torch with interchangable heads fed from a large bottle of Propane. I always use a torch head that is too large so the job heats up quickly.

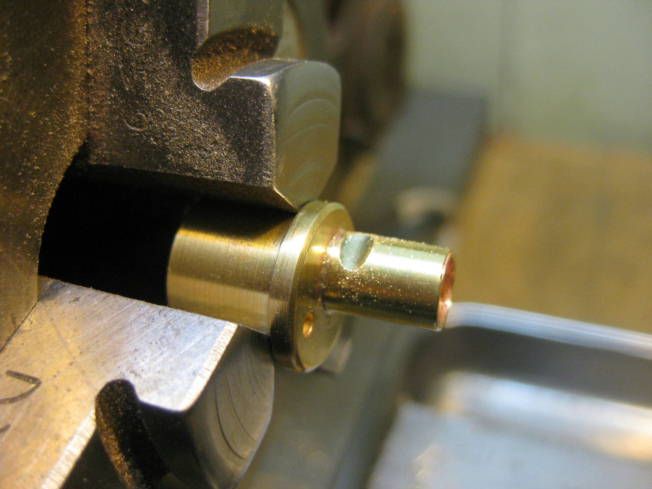

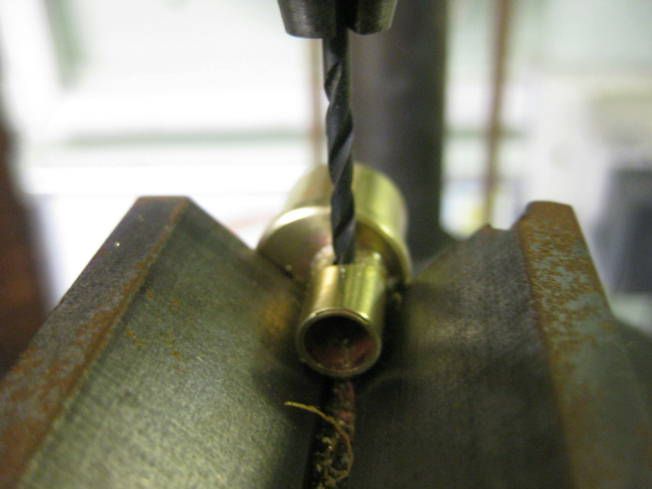

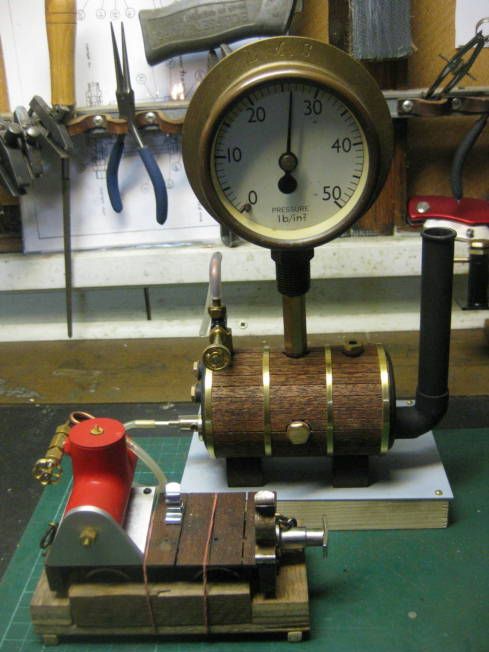

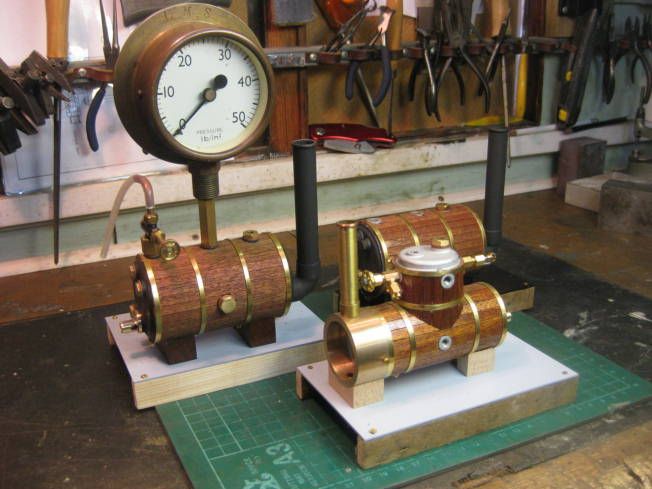

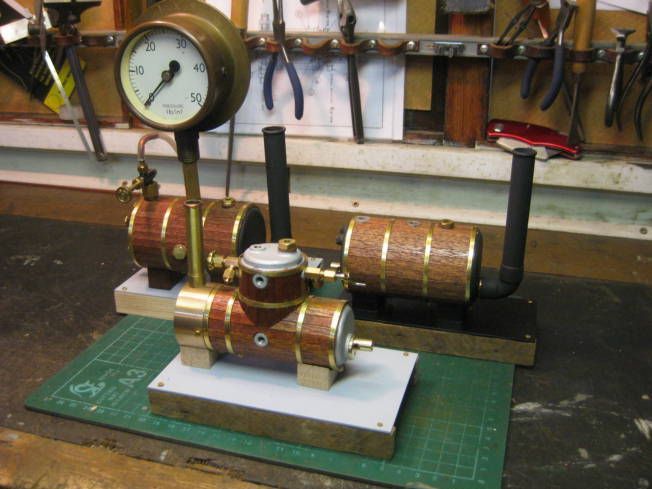

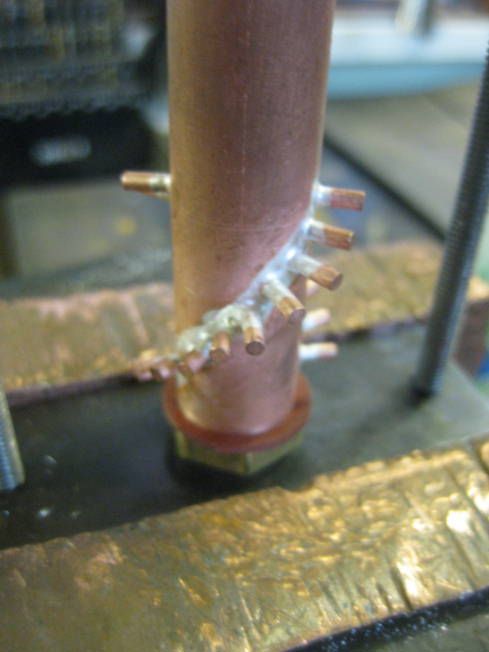

Your silver brazing looks good and the pickling good too. Very professional.Mine tends to run all over.

Solder will run over any part of the job that has flux on it so paint the flux on carefully where you want the solder. Warm the joint slowly so the water content of the flux mixture evaporates rather than boils and runs all over the place. Hope this helps.

Regards Tony.

Sorry I cannot help withyour glow plug problems.

Please advise silver solder rod content. I use higher silver content for ease of brazing. Air conditioners' silver solder rod can be tough to melt and run. Plan to buy a double torch Mapp Gas Torch after watching demo.

At the moment I am using Easyflo No.2 silver solder and flux which melts at about 640C. Sorry I don't know how this compares with solders used in the USA. The pickle I use is Citric acid which I get from Home Brew/Wine stores. The powder is mixed in hot water until the mix is saturated. I.e. when crystals that won't desolve appear in the mix. I use a plumbers gas torch with interchangable heads fed from a large bottle of Propane. I always use a torch head that is too large so the job heats up quickly.

Your silver brazing looks good and the pickling good too. Very professional.Mine tends to run all over.

Solder will run over any part of the job that has flux on it so paint the flux on carefully where you want the solder. Warm the joint slowly so the water content of the flux mixture evaporates rather than boils and runs all over the place. Hope this helps.

Regards Tony.