I have 5 different air/steam engines that I want to run off a common manifold at a steam fair. I will run them all at full (80 pounds) of pressure off an air compressor. Some of these engines are real air hogs, others just need a small amount of air. I plan on regulating the speed of the engines by adjusting the amount of air flowing thru the individual valves. I need to find a source for a manually controlled valve that has a good range of adjustment and has a barb on the outflow end to accept a 1/8" inner diameter neoprene tube. The inflow end should be an NPT thread that I can screw into a home made manifold. The valves will be made of brass. Any good suggestions on where I can source valves like this? (Hopefully in Canada)----Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Small air control valves???

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Hi BR,

Sorry their not in Canada. They do have a Chicago facility.

3 pages of stuff

http://www.mcmaster.com/#pneumatic-valves/=2vxe3i

You might want to look into a company called Festo

Tony

Sorry their not in Canada. They do have a Chicago facility.

3 pages of stuff

http://www.mcmaster.com/#pneumatic-valves/=2vxe3i

You might want to look into a company called Festo

Tony

I'm on my way over to the local SMC rep on the other side of Barrie. I work with them quite a lot on different machine systems I design, as they are my primary pneumatics supplier. They say that they have what I'm looking for.--Will post whatever I find.---Brian

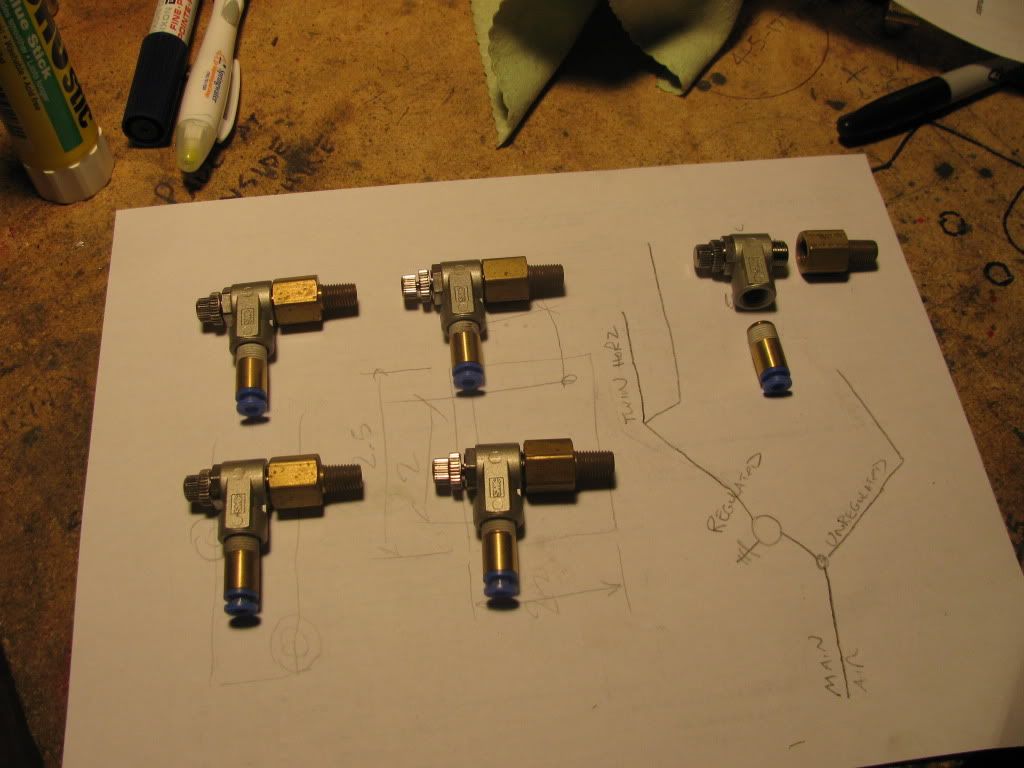

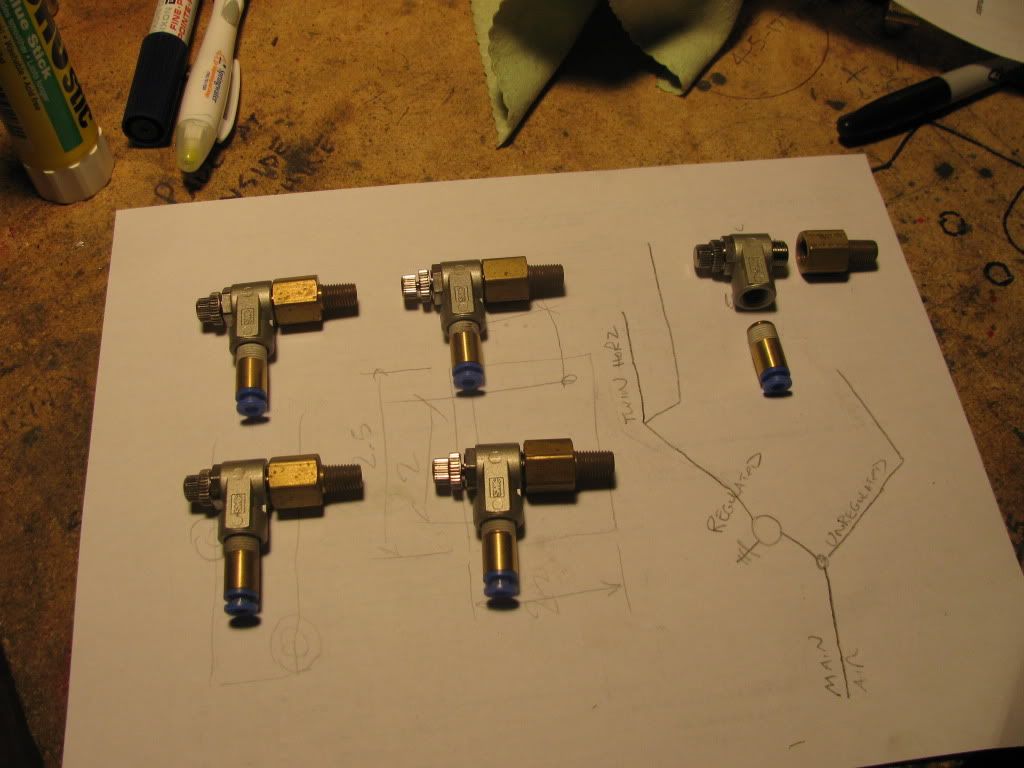

I got everything I needed over at the SMC dealers. --Not cheap though---It spoiled $100. I got 5 flow controls, 5 adapters to solder into a home built manifold, and 5 "push-fit" fittings which I will rework to use with my 1/8" i.d. neoprene hose. I will keep posting here as I build the air distribution manifold. I did try one of the flow controls while I was there, and they give a very fine contol over the speed of a motor, even though the pressure was a constant 80 PSI.

Tel--I had heard about aquarium valves being used, but I couldn't find any locally. As far as building them myself---I probably could have, but not between today and next weekend when I'm supposed to exhibit these engines.

- Joined

- Jul 16, 2007

- Messages

- 2,987

- Reaction score

- 1,055

Hi Brian,

Tel had a good answer. When I started out I used a multiple aquarium manifold for my engines then I moved up to the one I showed the thread of. I know it's alot of work but I thought it fit the character of my engines better than the aquarium piece.

Here's the link to the one I made:

http://www.homemodelenginemachinist.com/index.php?topic=5048.msg51723#msg51723

gbritnell

Tel had a good answer. When I started out I used a multiple aquarium manifold for my engines then I moved up to the one I showed the thread of. I know it's alot of work but I thought it fit the character of my engines better than the aquarium piece.

Here's the link to the one I made:

http://www.homemodelenginemachinist.com/index.php?topic=5048.msg51723#msg51723

gbritnell

steamboatmodel

Well-Known Member

- Joined

- Sep 7, 2008

- Messages

- 303

- Reaction score

- 7

Hi Brian,Brian Rupnow said:Tel--I had heard about aquarium valves being used, but I couldn't find any locally. As far as building them myself---I probably could have, but not between today and next weekend when I'm supposed to exhibit these engines.

When and where are you exhibiting your engines?

Regards,

Gerald

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

steamboatmodel said:Hi Brian,

When and where are you exhibiting your engines?

Regards,

Gerald

At the Cookstown, Ontario steam show on Aug 1 and 2---Next weekend.---Brian

Maybe not a good answer but worked for me. A home made jobby.

Drilled length of steel for common in air and taped for pipe fitting to air supply.

Drilled from one side to common supply hole with the ID of some urethane tubing. Then drilled just short of getting to the supply hole with OD size of the urethane tubing. Drilled and tapped holes for hose barbs. A short length of urethane tubing (the urethane tubing has good memory and will return to original shape like a spring) The length of tubing is cut to a length that will be sealed at both ends when hose barb is screwed in.

From top a hole is drilled and tapped that will intersect where the center of short length of urethane tubing will be.

Drop a steel ball in this hole and screw in a screw which will be your control valve. When screwed down tight the steel ball squishes the tubing shutting of the air.

Don't have picture handy but found sketch (top view) when made it. Can take pictures if anyone interested....... gary

Drilled length of steel for common in air and taped for pipe fitting to air supply.

Drilled from one side to common supply hole with the ID of some urethane tubing. Then drilled just short of getting to the supply hole with OD size of the urethane tubing. Drilled and tapped holes for hose barbs. A short length of urethane tubing (the urethane tubing has good memory and will return to original shape like a spring) The length of tubing is cut to a length that will be sealed at both ends when hose barb is screwed in.

From top a hole is drilled and tapped that will intersect where the center of short length of urethane tubing will be.

Drop a steel ball in this hole and screw in a screw which will be your control valve. When screwed down tight the steel ball squishes the tubing shutting of the air.

Don't have picture handy but found sketch (top view) when made it. Can take pictures if anyone interested....... gary

For UK based members, the ones shown down a bit on this page would be ideal.

http://rdgtools.co.uk/acatalog/AIR_BRUSH_HOSES_AND_EQUIPMENT.html

At those prices, they are not worth making yourself.

Blogs

http://rdgtools.co.uk/acatalog/AIR_BRUSH_HOSES_AND_EQUIPMENT.html

At those prices, they are not worth making yourself.

Blogs

R

RobWilson

Guest

Blogwitch said:For UK based members, the ones shown down a bit on this page would be ideal.

http://rdgtools.co.uk/acatalog/AIR_BRUSH_HOSES_AND_EQUIPMENT.html

At those prices, they are not worth making yourself.

Blogs

Good idea Blog,great price

Rob

FWIW, the little all-brass "in-line regulators" are just little valves (cross-drill a bit of hex, insert rod with cross-hole and knob, thread the ends). There's not any other 'regulation' going on, but if that's acceptable, they work ok. I use them for coolant valves on my little CNC machine and they don't leak much. Available at Harbor Freight and other places in the US... $2.99 last I looked-- not worth the time to make one, but the concept could be useful in a larger block.Blogwitch said:For UK based members, the ones shown down a bit on this page would be ideal.

http://rdgtools.co.uk/acatalog/AIR_BRUSH_HOSES_AND_EQUIPMENT.html

At those prices, they are not worth making yourself.

Blogs

I also like the urethane-tube-squeezer idea; my mini sandblaster uses that method as blast media valve and it works very well, although in heavy use you do have to move the squeezed-on bit occasionally to keep it from wearing through. For a show, you could run urethane all the way to the motors from an octopus block and put a squeeze-valve on the air lines anywhere as well.

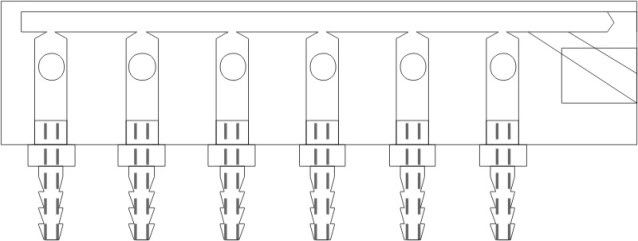

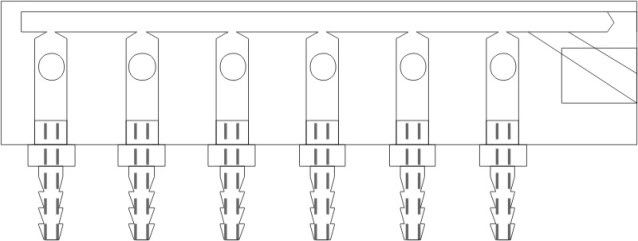

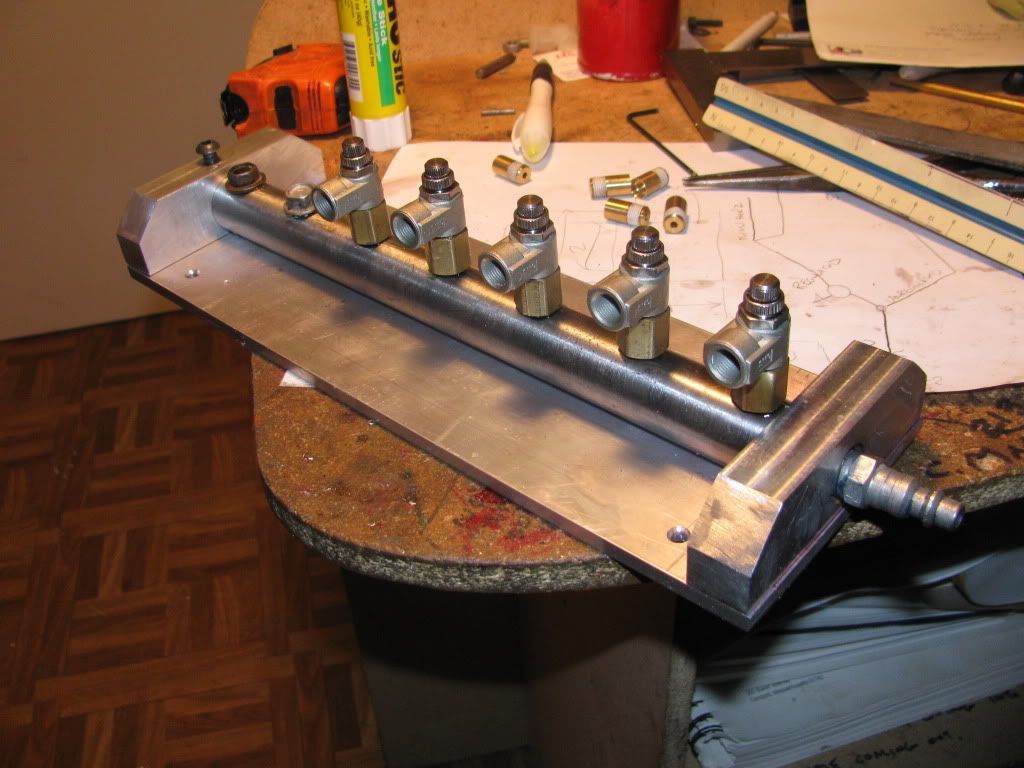

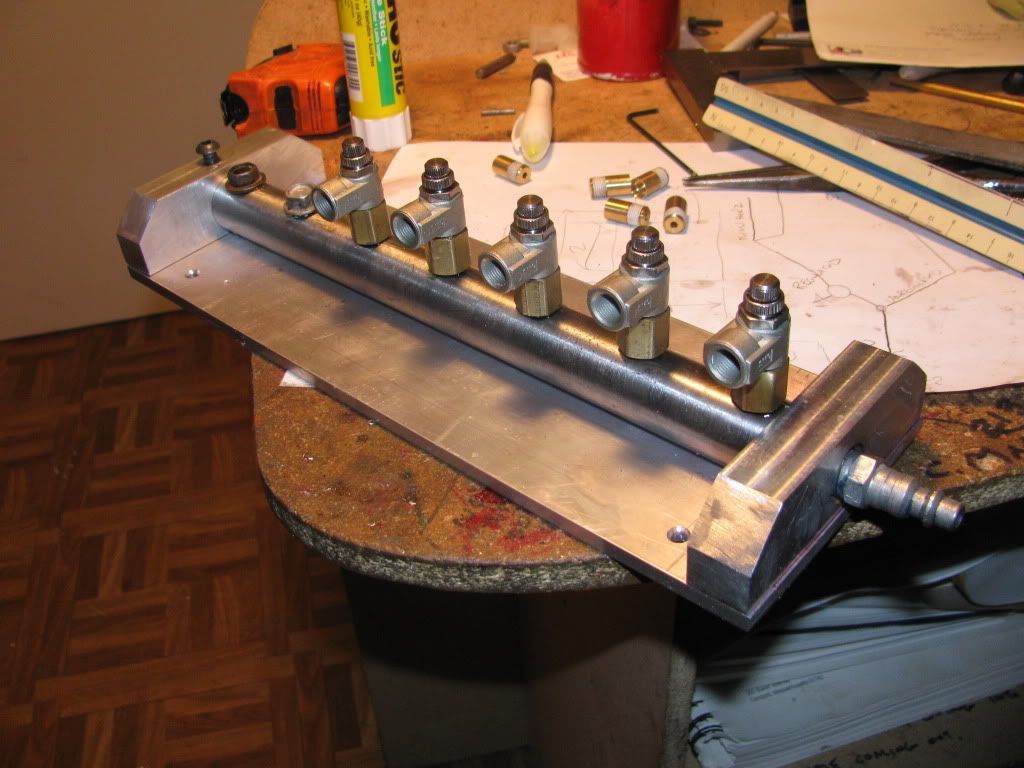

Okay---Here we go--almost done. Not as fancy as some, but very functional. I have valves for 5 engines and two "extra" ports for possible future expansion. The main air chamber is a peice of 1" O.D. steel tube with a 1/8" wall thickness, and a bunch of aluminum bits from my scrap bin. I still have to machine some adapters to solder into the brass bits in the background. These brass bits will then screw into the flow control valves.

Similar threads

- Replies

- 19

- Views

- 1K

- Replies

- 0

- Views

- 665

- Replies

- 61

- Views

- 11K