I've reached in the back of the tool cabinet for some of the tooling I don't use much (honestly, "at all" would be closer) but keep around because they make "that one job" easier.

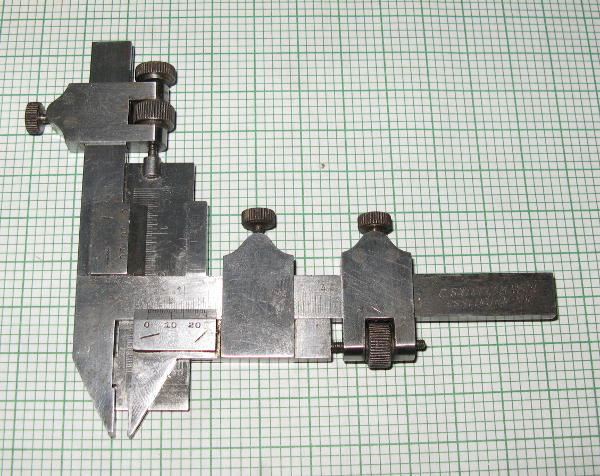

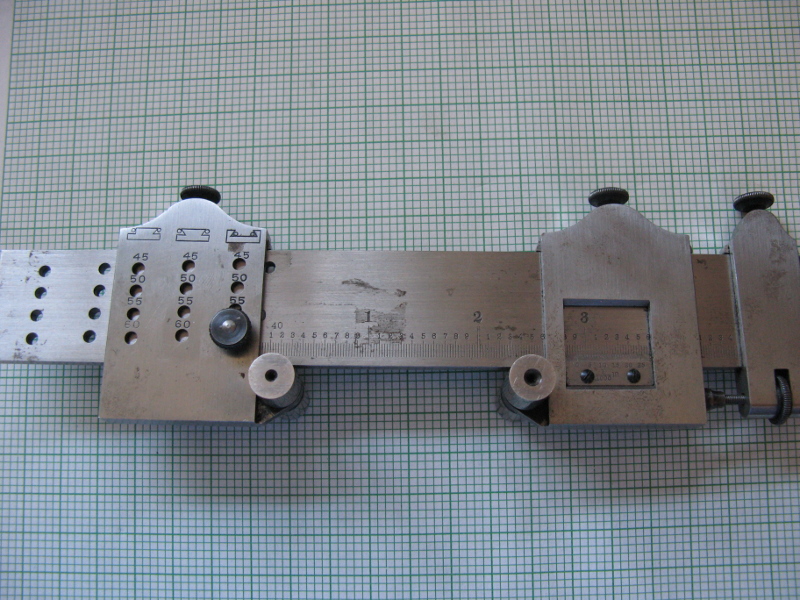

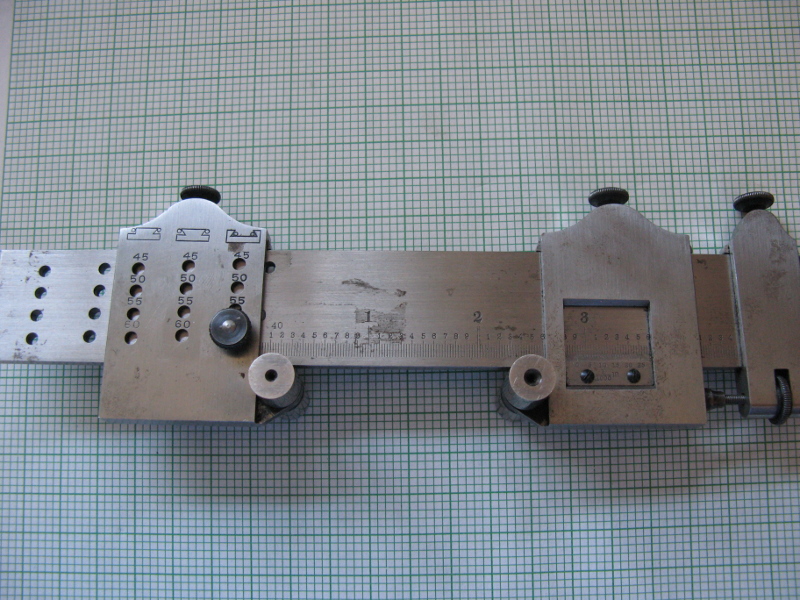

Here's one of those tools - a direct reading vernier dovetail caliper, a Starrett 438.

It will read inside and outside dovetails of 45, 50, 55 and 60 degrees directly. I haven't seen many of these. I think I've used it a dozen times and really gage pins or dowels and an adjustable parallel are usually more convenient, but there's some cool factor in this tool.

Here's one of those tools - a direct reading vernier dovetail caliper, a Starrett 438.

It will read inside and outside dovetails of 45, 50, 55 and 60 degrees directly. I haven't seen many of these. I think I've used it a dozen times and really gage pins or dowels and an adjustable parallel are usually more convenient, but there's some cool factor in this tool.