kennycrawford

Member

- Joined

- Dec 9, 2011

- Messages

- 11

- Reaction score

- 0

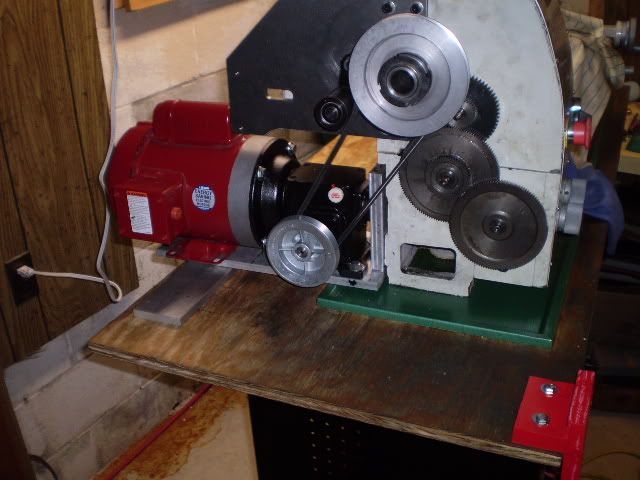

I own a Grizzly 9729 that I purchased new just over 2 and 1/2 years ago. Being my first machine I was pretty happy with the lathe aspect but disenchanted with the milling part. Long story short I now own a 9x19 lathe a BF20 mill and a Taig set up. Like I mentioned the 9729 as a lathe I thought was good.....until last week when the motor decided to not consistantly start. It also started making a "sparking" noise on start up. The motor will function if you start it spinning before energizing the start button. I even made a cut on it to see if the motor was producing power. I cleaned up the start motor contacts with a point file, because I found them pitted but that did not fix it. The capacitors don't show any signs of damage but then again I don't know if they would. I would not be opposed to using this opportunity to upgrade to a variable speed system but have no experience and don't know where to start. Any advice would be appreciated as to what some viable options may be.

Thank you,

Kenny

Thank you,

Kenny