Don1966

Senior Member

- Joined

- Jan 19, 2012

- Messages

- 487

- Reaction score

- 24

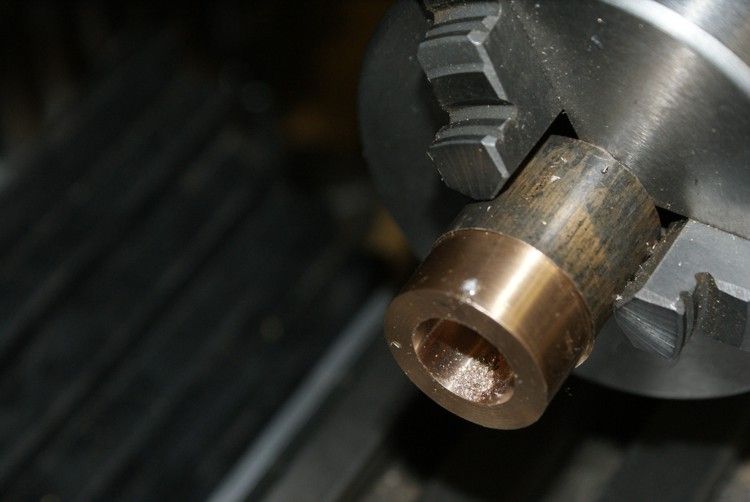

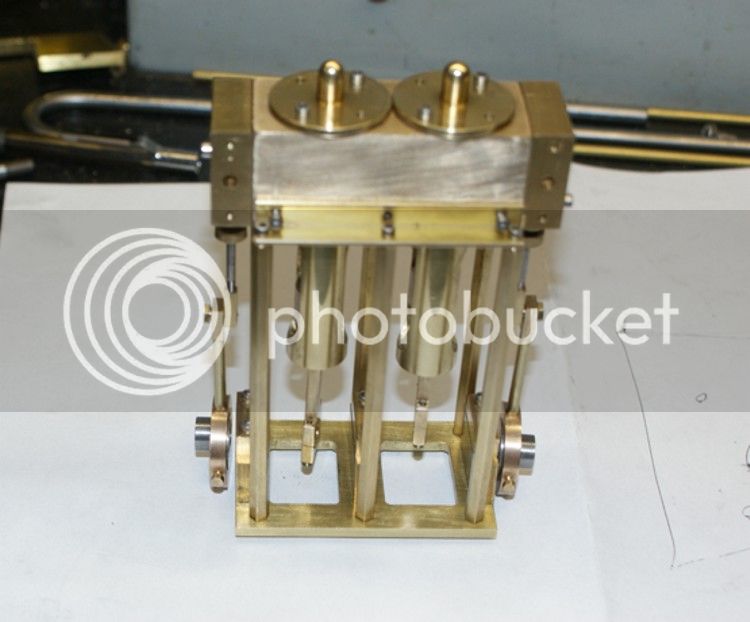

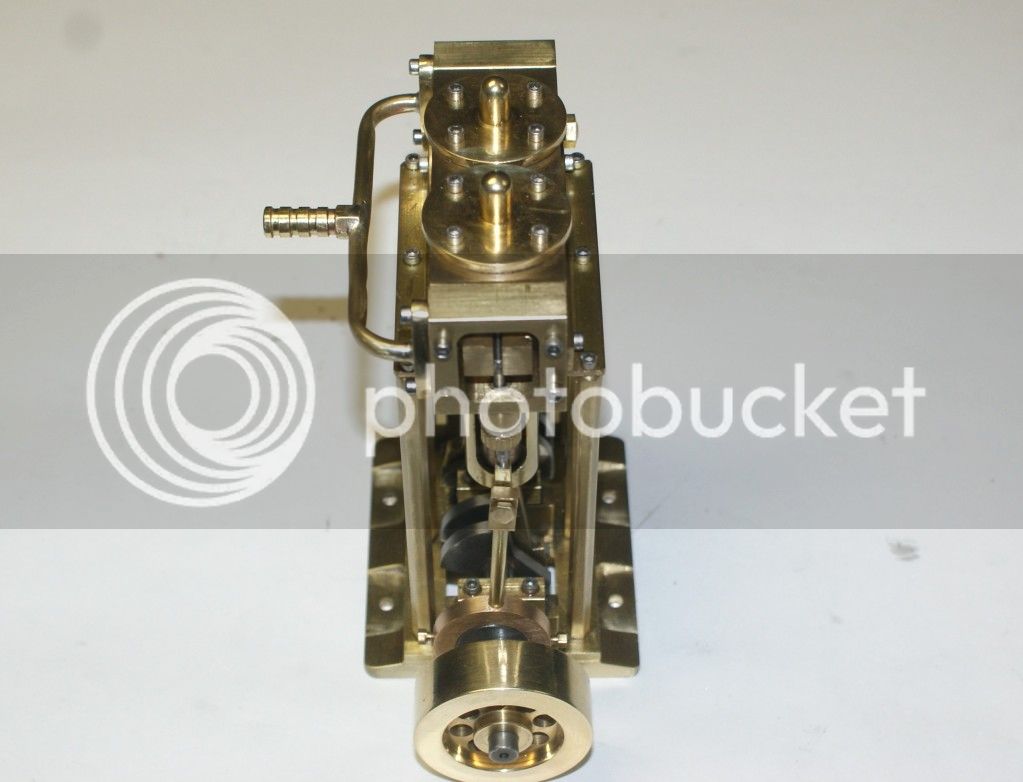

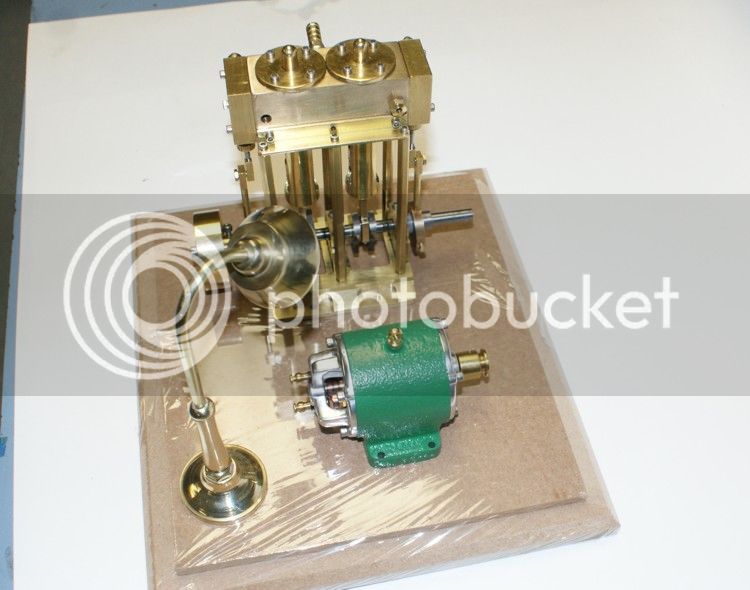

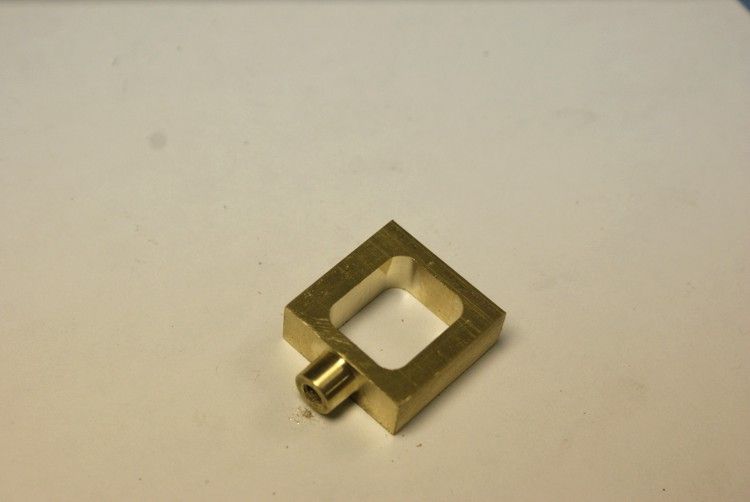

I had started this engine before I started taking photos and documenting. I have attached the photo of the parts that were already made and will start for there to the final assembly. The cylinder is made from bronze, the shaft and throw lobs were made from tool steel, steam chest is brass, piston and steam chest linkage stainless and the frame and steam chest all brass.

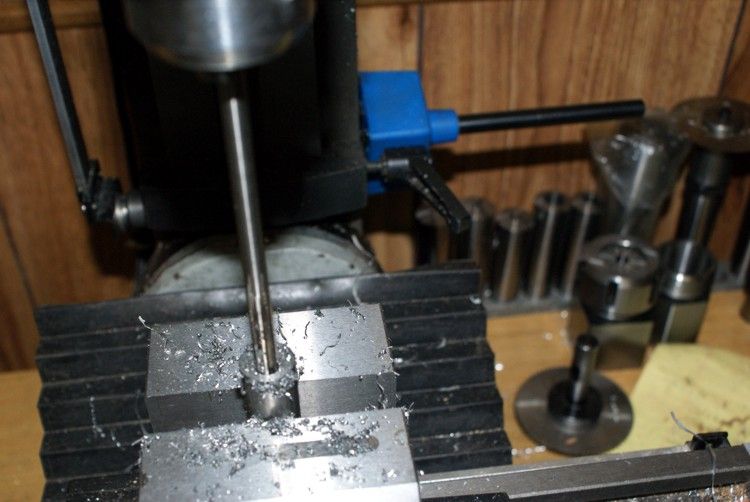

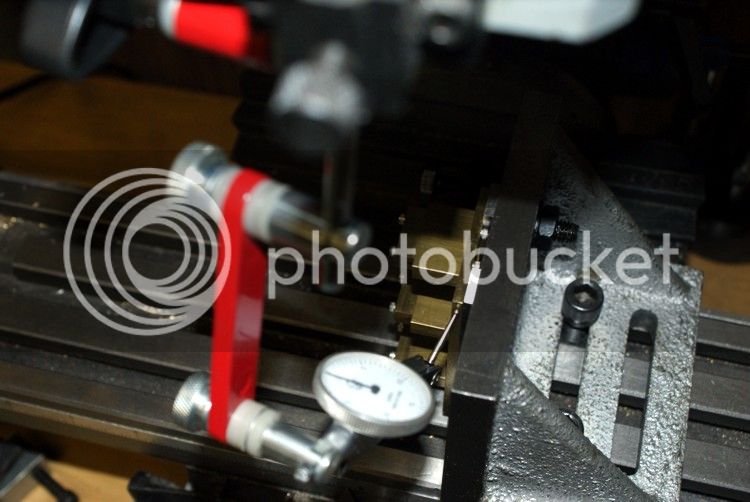

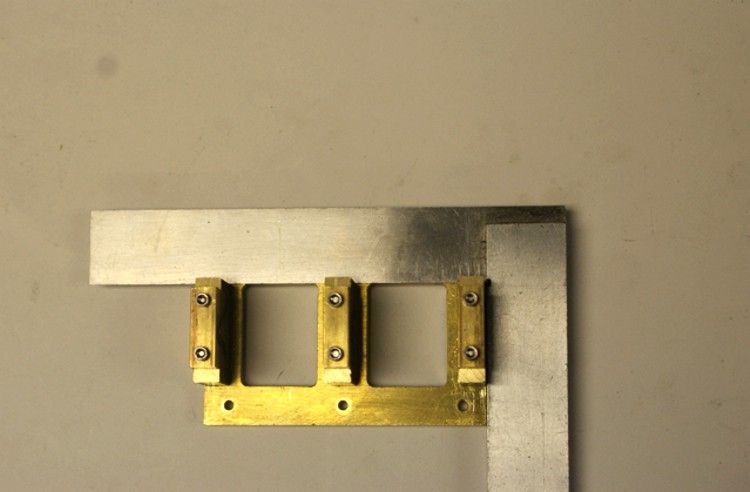

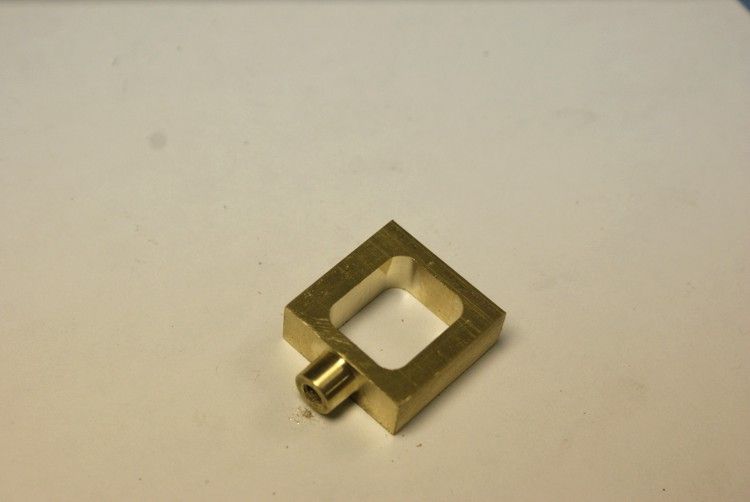

Squaring off the pillar block bearings

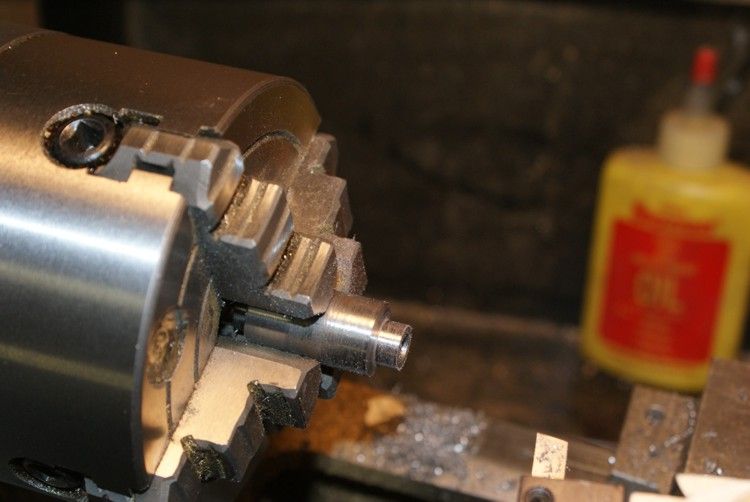

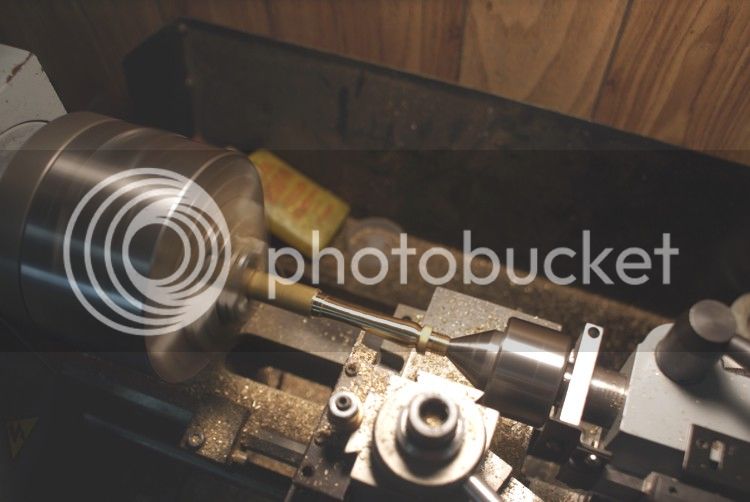

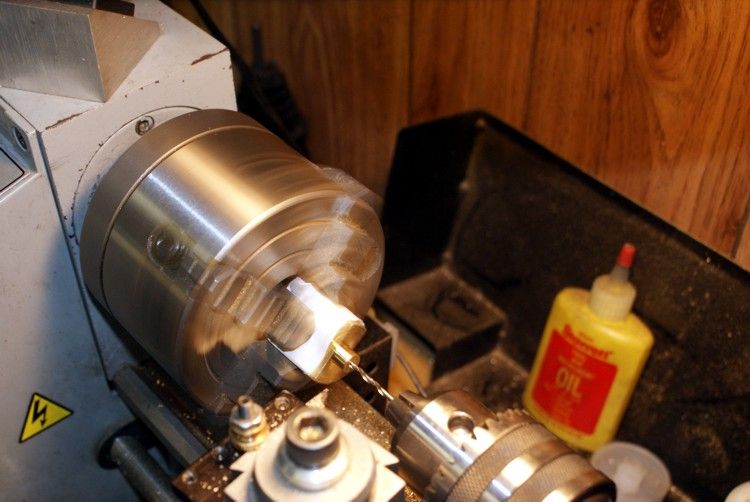

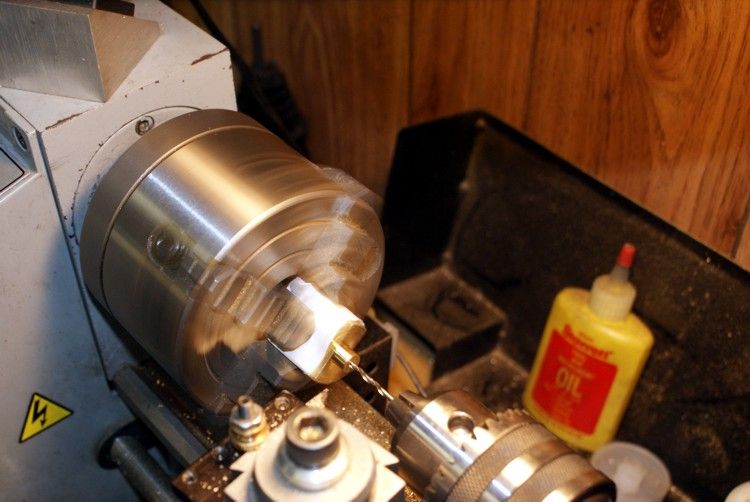

I will start by setting up the steam chest into the lathe and align it with the laser to the center punch mark and Boring and reaming.

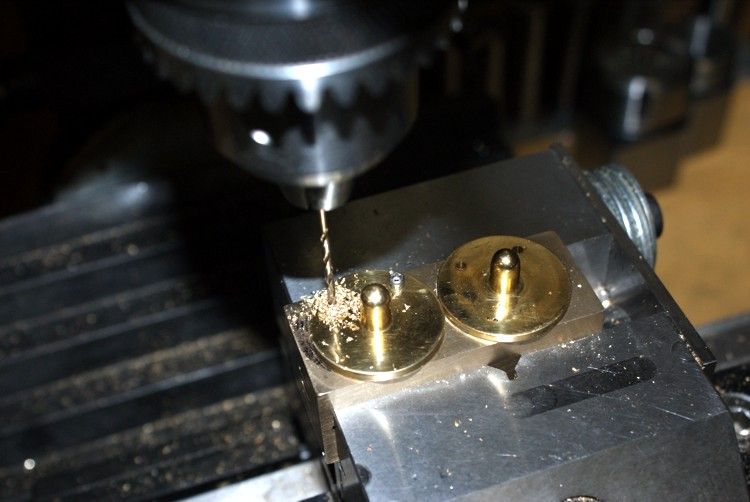

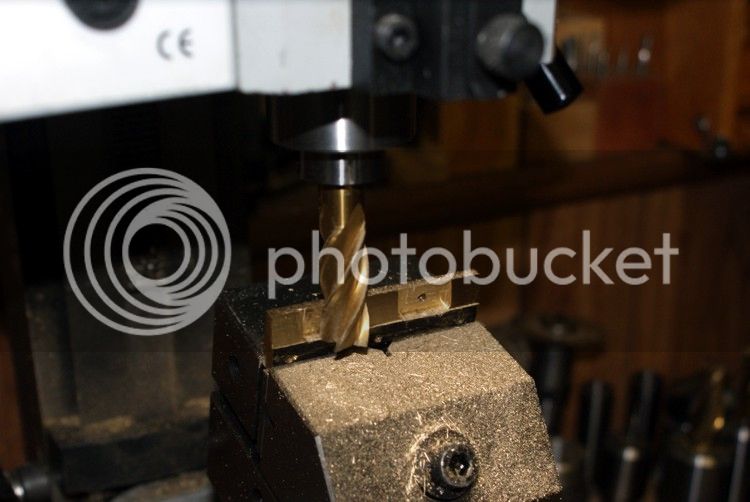

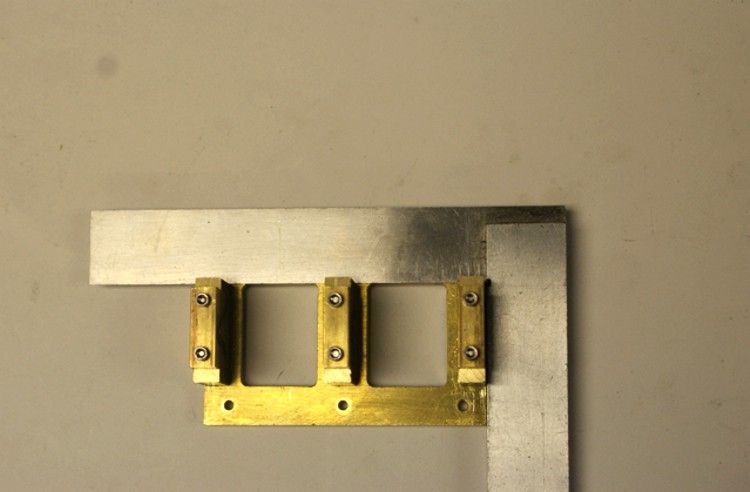

Now I set it up in the mill and mill the steam passage.

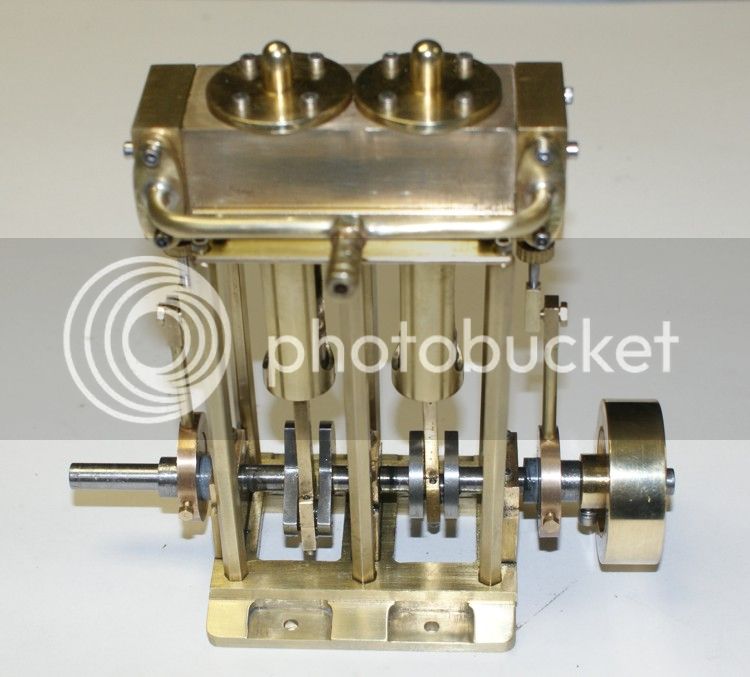

Milling complete

Will thats all for today

Don

Squaring off the pillar block bearings

I will start by setting up the steam chest into the lathe and align it with the laser to the center punch mark and Boring and reaming.

Now I set it up in the mill and mill the steam passage.

Milling complete

Will thats all for today

Don