I also use photoresist board (Kinsten brand)

I've never used transparency film, cheap tracing paper(I think it is actually a plastic) from a stationary supply works fine for me, been using it for over a decade without issue.

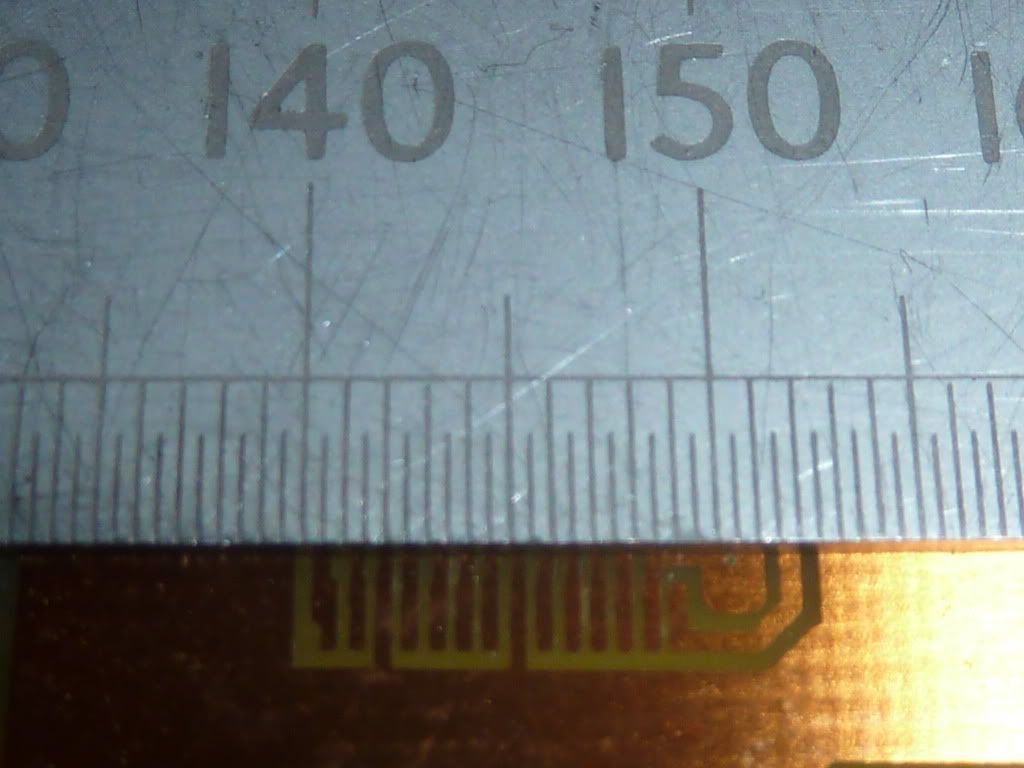

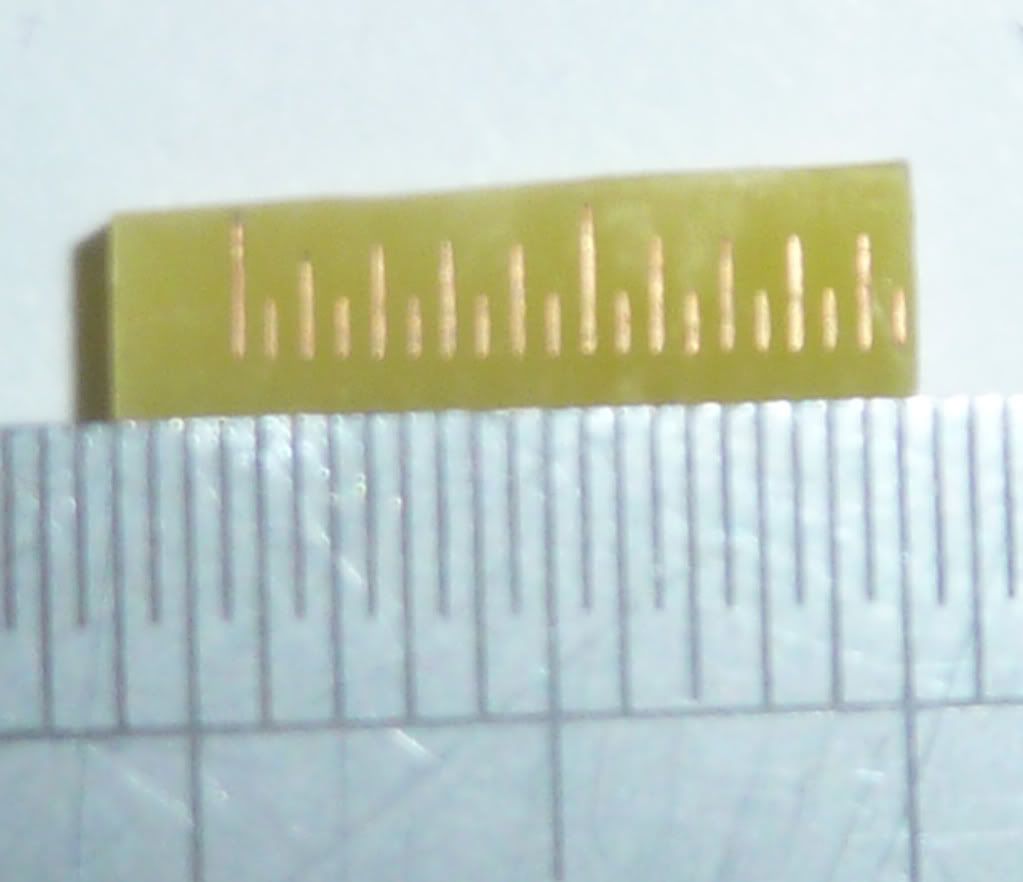

Photoresist has amazing resolution, early-on I was getting pin holes and rough edges on my tracks which drove me insane. Trying to find the problem I eventually used a low powered microscope to compare the tracks and the laser prints, the tracks were exact copies. The rough edges were due to the 600LPI resolution of the printer!

I also was worried about the density of laser prints when I started, but it has never been an issue except for the occasional tiny pin hole which I think is more dependent on the quality of the printer.

The biggest issue I have had is distortion. I have never once used a laser printer that scales correctly.

To correct, I print a test page with an x-y scale I made up in CAD years ago to fit an A4 sheet, then measure the error with a rule and correct for it when I print the artwork. Check again and things are usually pretty close.

It's not a big issue for thru-hole components, but can be for fine-pitch SMD or BGA chips.

I simply use the Sun to expose my boards, it's cheap(free!) and takes about 30 seconds to a min or so depending on season(and latitude). Only problem is it is not always around!

A hang-over from my photography darkroom days, I used to do an exposure test strip; print a strip of numbers in 5 second increments and then expose a thin slice of board, uncovering a new number every 5 seconds from the 60(or whatever) second end to the 5 second end. Develop, strip, etch and check for best exposure.

If that doesn't make any sense, do a google search for "darkroom test strip"

I've found the Kinsten brand resist has a fair exposure latitude anyway. Possibly the same for other brands.

I had something else to share too, but forgot what it was, I have blah blah blah long enough now anyway! haha