Thanks Ernie/Jim

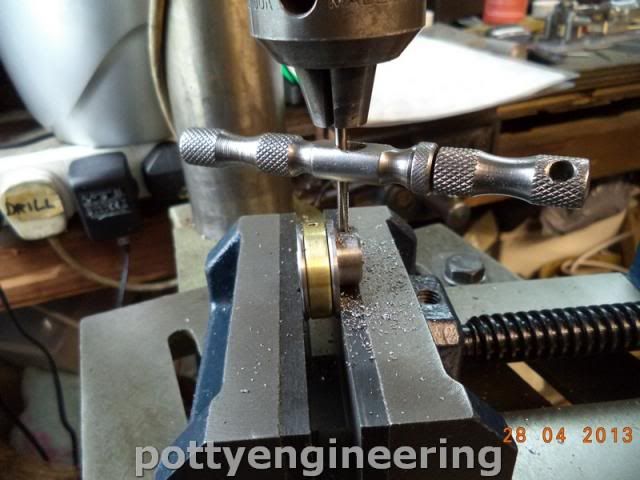

I'm waiting on some steel tube to make the fly wheel so decided to get on and finish the bed plate off, I carfully marked the position for the crank bearing and drill them out 2.7mm clearance on M2.5. The bit of ally I made the bed plate from was 3" wide I wanted 2" but that was all I could get so had to cut it down, using a hack saw and a guide plate, so that things didn't wander off.

Then filed the cut off level, noting too fussy just as long as it doesn't offend the eye.

The drill 4 corner holes and filed some fancy rads on the corners.

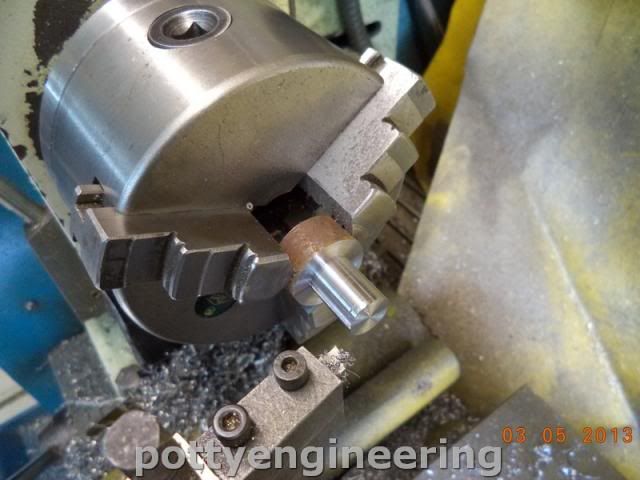

Assembled the engine back to the bed plate, and fixed a carrier to the crank shaft to try and turn it over, turned over ok, but the valve rod thing fouled, did a bit of adjustment, phew ther's enough clearnace for it travel its full movement, I roughly set the valve and spent 1/2" turning it over by hand it nows turn over nice and free.

Can't wait for that steel to arrive.

Decided to make the base, these sort of engine often stood on stone plyths, so got hold of some chip board, cut two bits off to size and rounded the edge, then cut and filed some nicks along the edge to simulate the stone courses.

This is what it looks like.

I'll give it some licks of paint I'm hoping that it will keep its rough texture to look like stone. I aplied some wood glu and clamp them together, I'll see what they are like tomorrow.

Stew