dan s

Active Member

- Joined

- Jan 25, 2008

- Messages

- 25

- Reaction score

- 0

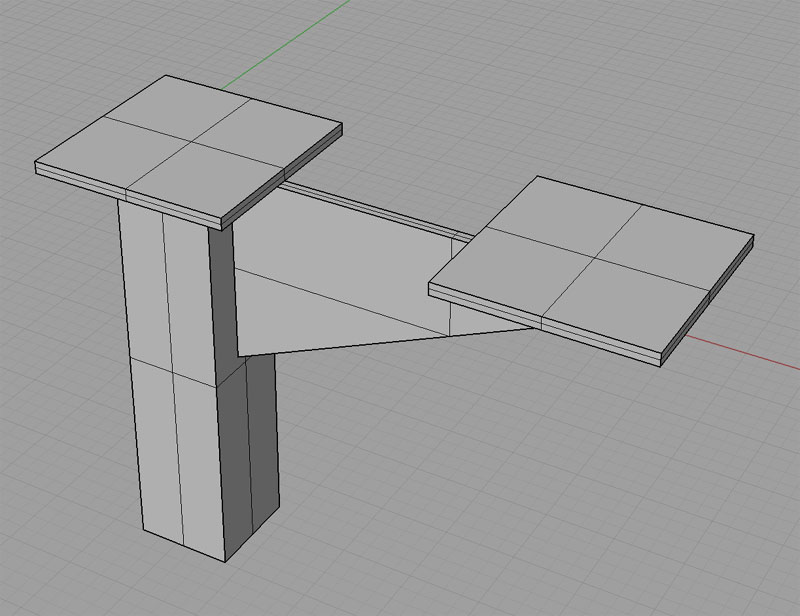

Im planning to make 2 new workbenches for my shop and before I started ordering material, I Wanted to run the design by everybody.

My design requirements are as follows:

1. Must be open underneath for role away tool storage.

2. Must be able to break it down for moving purposes

3. Must be able to handle a load of 1000 lbs (in case I get a bigger lathe ;D)

What I came up with is as follows:

Overall dimensions - W 72, D 30, H 40 44 (adjustable)

Top - 4 thick laminated hard maple. It should look pretty good when finished and provide good vibration dampening properties.

The legs & horizontal cross bracing are 2.5 x .12 square tubing

The rear diagonal bracing is 1-1/2 x 3/16 flat bar bolted to the legs. The theory is that since I have diagonals in both directions one is always under tension.

What does everyone think?

My design requirements are as follows:

1. Must be open underneath for role away tool storage.

2. Must be able to break it down for moving purposes

3. Must be able to handle a load of 1000 lbs (in case I get a bigger lathe ;D)

What I came up with is as follows:

Overall dimensions - W 72, D 30, H 40 44 (adjustable)

Top - 4 thick laminated hard maple. It should look pretty good when finished and provide good vibration dampening properties.

The legs & horizontal cross bracing are 2.5 x .12 square tubing

The rear diagonal bracing is 1-1/2 x 3/16 flat bar bolted to the legs. The theory is that since I have diagonals in both directions one is always under tension.

What does everyone think?