Hi all,

This is my first posting here, although I've been reading the forum for a while, with great interest. Now I need some help:

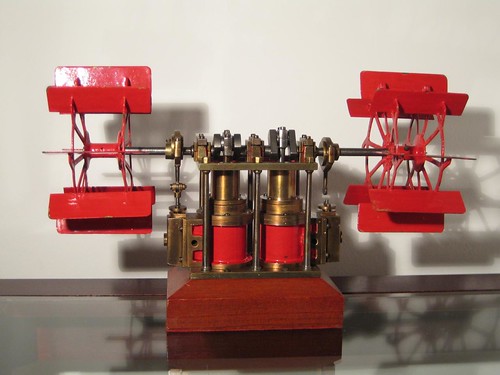

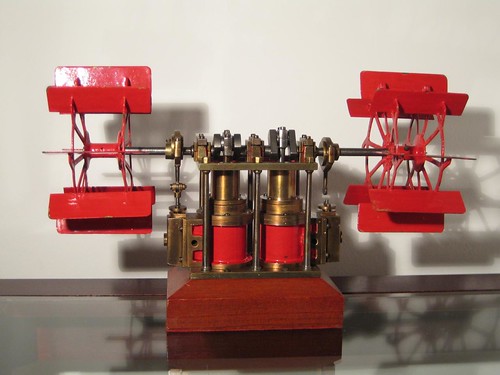

I have an engine here for identification. Bought it recently (without any history) and according to my Internet research it is called a "trunk steam engine". As you can notice, it is not the usual configuration. It is a double acting engine with slide valves, but, rather than having piston rods, it has a more peculiar arrangement: the piston rods are actually wide tubes and the con rods run into these tubes. The result is a very compact engine (the same size as an equivalent oscillator) but it is still having reasonably long con rods.

The following parts (at least) are made from bronze castings: cylinders, valve chests, base, crankshaft frame, eccentrics, eccentric straps.

Here are the pictures:

2010-11-07 007 by -kno3-2, on Flickr

2010-11-07 001 by -kno3-2, on Flickr

Does anyone know who made the castings, or perhaps the engine?

This is my first posting here, although I've been reading the forum for a while, with great interest. Now I need some help:

I have an engine here for identification. Bought it recently (without any history) and according to my Internet research it is called a "trunk steam engine". As you can notice, it is not the usual configuration. It is a double acting engine with slide valves, but, rather than having piston rods, it has a more peculiar arrangement: the piston rods are actually wide tubes and the con rods run into these tubes. The result is a very compact engine (the same size as an equivalent oscillator) but it is still having reasonably long con rods.

The following parts (at least) are made from bronze castings: cylinders, valve chests, base, crankshaft frame, eccentrics, eccentric straps.

Here are the pictures:

2010-11-07 007 by -kno3-2, on Flickr

2010-11-07 001 by -kno3-2, on Flickr

Does anyone know who made the castings, or perhaps the engine?