Hello every one!

I've been away from this forum too long and thought it would be time for a comeback.

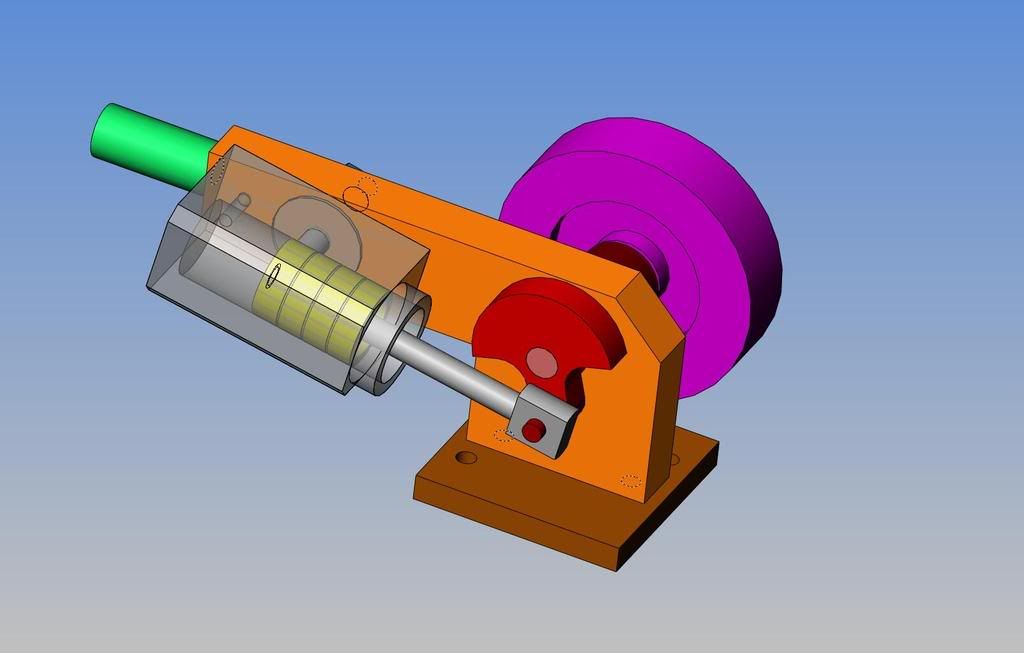

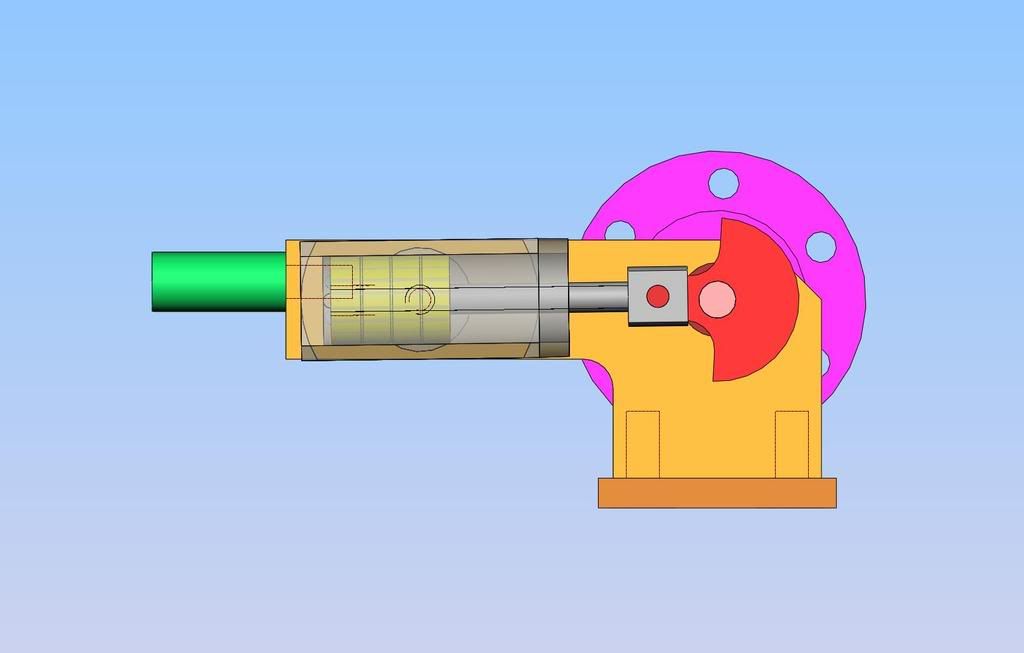

Still looking at different engine designs and no complete engine yet, just various parts laying around. Among them a cylinder I made some months ago. Can't remember which ozzy it belongs to so I thought that it might be possible to sort out the rest of the parts on my own.

So, to my questions; does it matter how close the piston goes from the cylinder top when at top dead center and how does the stroke affect the running?

Maybe this has been asked before and if so please forgive me.

/Alex

I've been away from this forum too long and thought it would be time for a comeback.

Still looking at different engine designs and no complete engine yet, just various parts laying around. Among them a cylinder I made some months ago. Can't remember which ozzy it belongs to so I thought that it might be possible to sort out the rest of the parts on my own.

So, to my questions; does it matter how close the piston goes from the cylinder top when at top dead center and how does the stroke affect the running?

Maybe this has been asked before and if so please forgive me.

/Alex