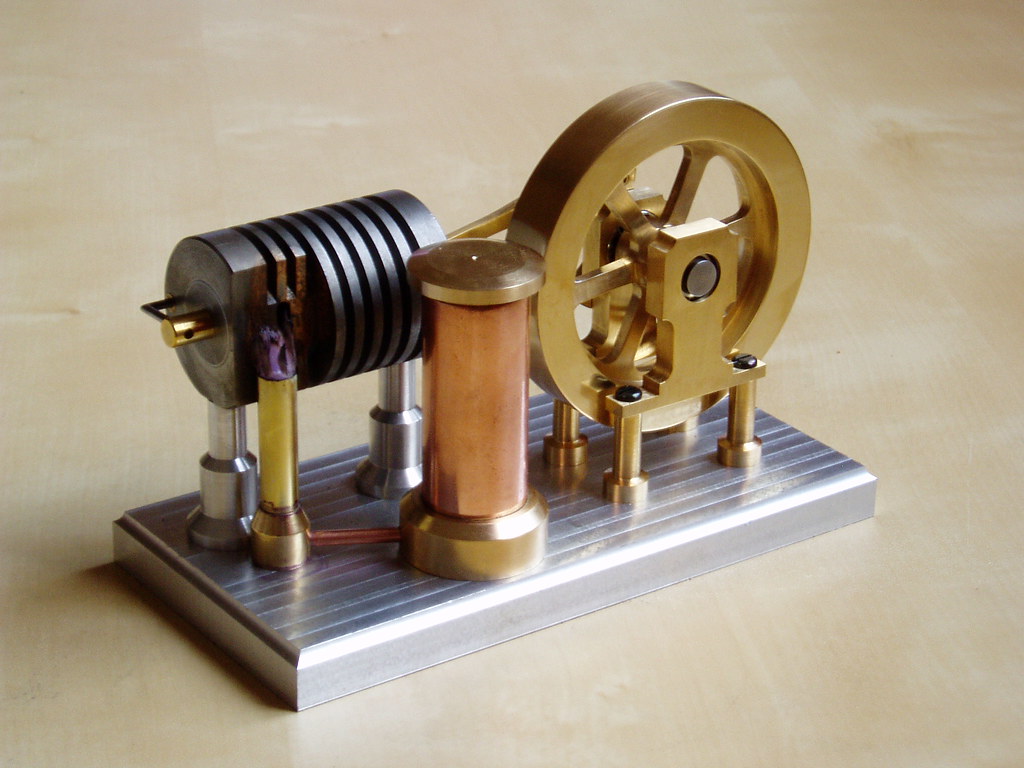

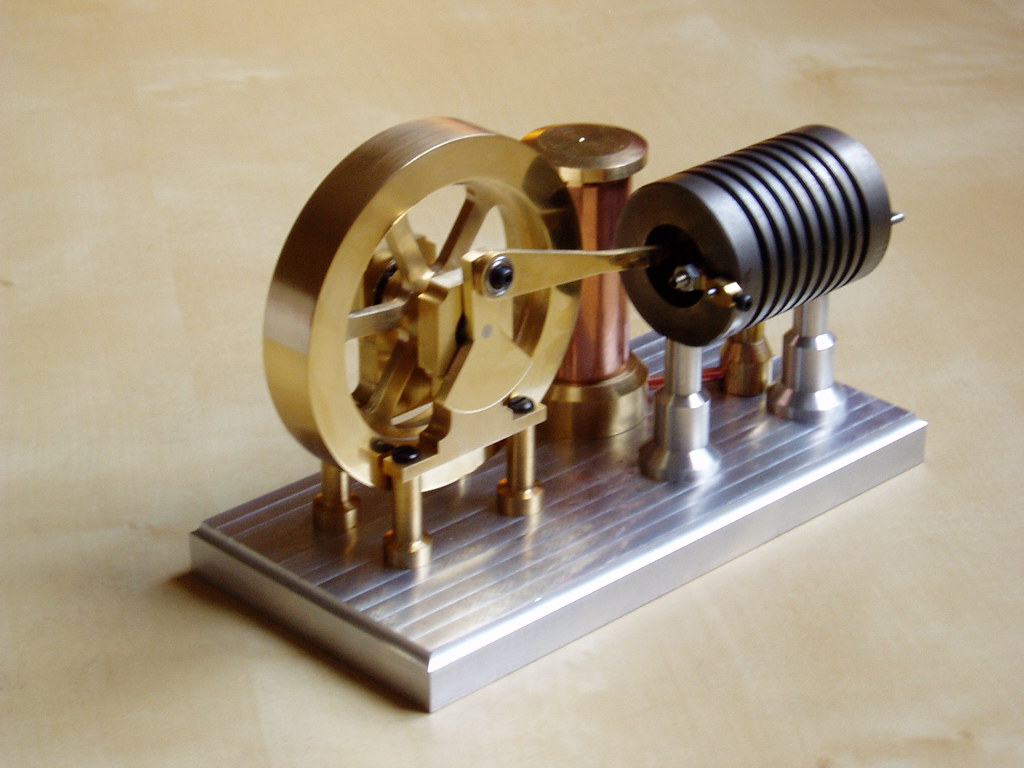

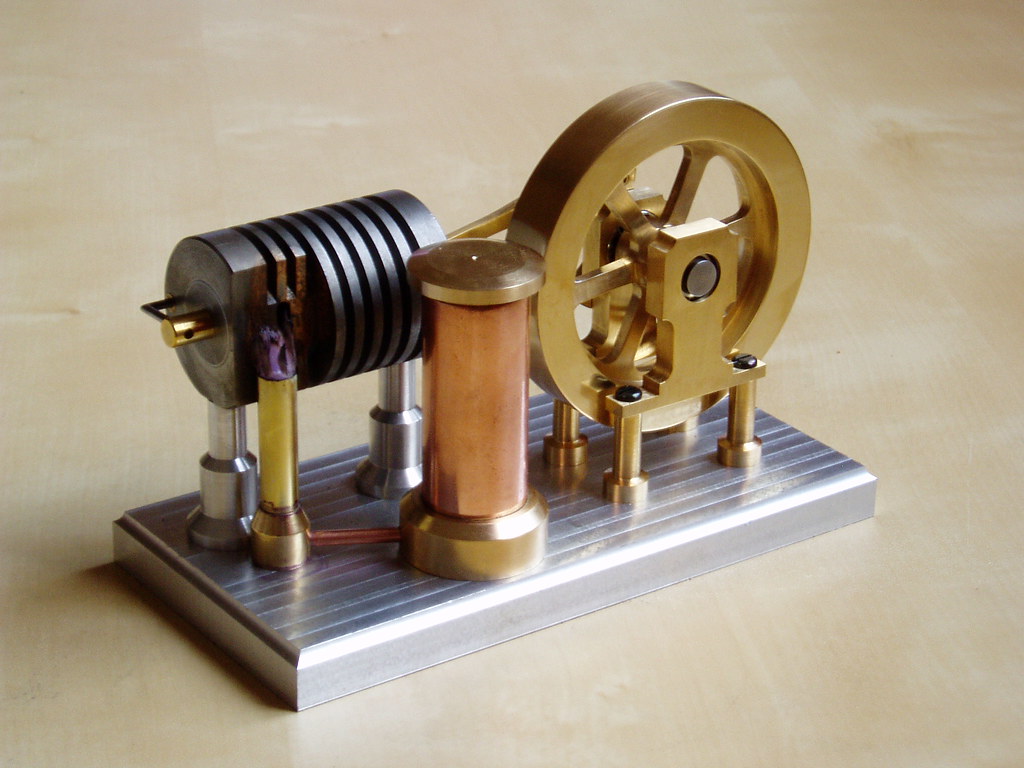

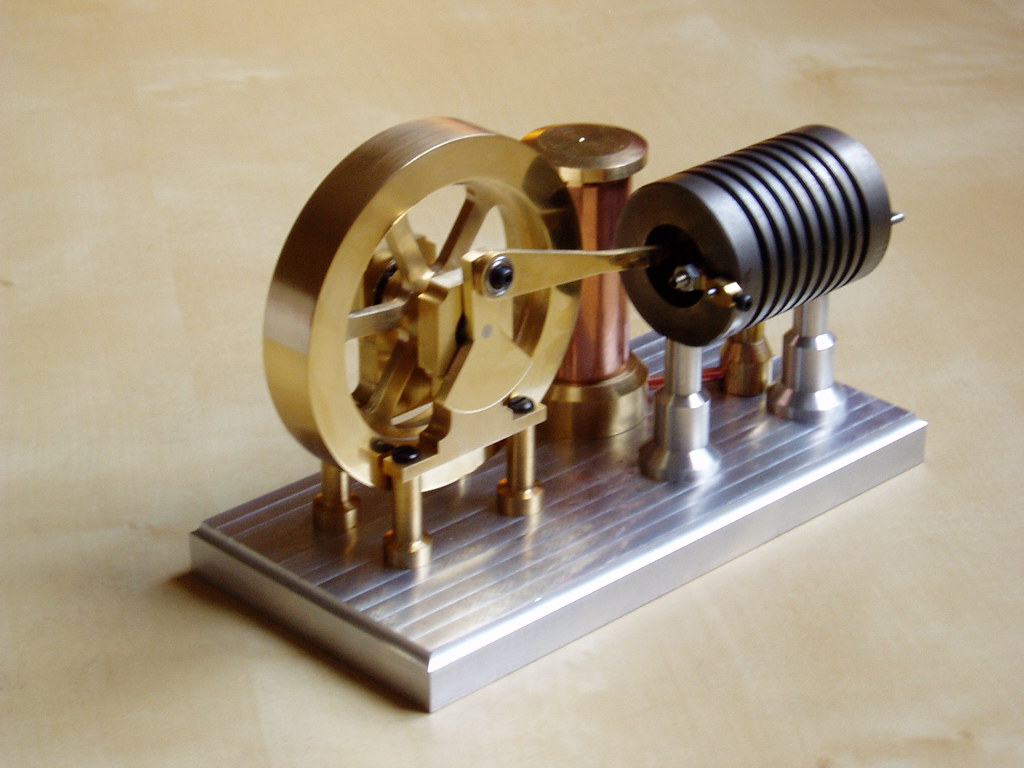

Well my first bit of proper metal bashing from my mid life crisis purchase of a lathe. And it actually runs! Which is a relief!

It's yet another Jan ridders flame licker

I built a different burner after reading bogstandard's comments on here - and I'm still grateful for him pointing me in the direction of this site in the first place. Now I know how I should have built it

I don't think there's a single component on it which doesn't have some fault. I still don't know the correct way to do things, but I've learnt loads of ways how not to

The engine's currently very fussy about the flame position, and when I finally got the thing to run, it only ran at about 180rpm.

I think there might be a couple of reasons for this. Firstly when watching the flame get sucked in, the bottom 1-2mm of the port looks flame free, so I'm going to try reducing the height of the burner pipe. Secondly the internal finish of the cylinder certainly isn't the glass like finish that others have described. I just made the cylinder a tight fit on the pistons then covered them in coarse metal polish and twisted them back and forth until they slipped through the cylinder under their own weight. But there's still plenty of visible machining marks on both the pistons and cylinders, so I might make a for the cylinder and then some new pistons.

Other outstanding jobs are making a base and finishing the surfaces on some of the components and maybe adding some grip indents on the fuel tank lid. But at the moment I'm just pleased that it finally spluttered into life.

[ame]http://www.youtube.com/watch?v=Jn3fmsywduA[/ame]

It's yet another Jan ridders flame licker

I built a different burner after reading bogstandard's comments on here - and I'm still grateful for him pointing me in the direction of this site in the first place. Now I know how I should have built it

I don't think there's a single component on it which doesn't have some fault. I still don't know the correct way to do things, but I've learnt loads of ways how not to

The engine's currently very fussy about the flame position, and when I finally got the thing to run, it only ran at about 180rpm.

I think there might be a couple of reasons for this. Firstly when watching the flame get sucked in, the bottom 1-2mm of the port looks flame free, so I'm going to try reducing the height of the burner pipe. Secondly the internal finish of the cylinder certainly isn't the glass like finish that others have described. I just made the cylinder a tight fit on the pistons then covered them in coarse metal polish and twisted them back and forth until they slipped through the cylinder under their own weight. But there's still plenty of visible machining marks on both the pistons and cylinders, so I might make a for the cylinder and then some new pistons.

Other outstanding jobs are making a base and finishing the surfaces on some of the components and maybe adding some grip indents on the fuel tank lid. But at the moment I'm just pleased that it finally spluttered into life.

[ame]http://www.youtube.com/watch?v=Jn3fmsywduA[/ame]