Peter,

A few years ago I bought a boring head second hand that did everything that mine now does, but the mounting spindle was bent. I paid 35bucks for it and was repaired in about an hour, but like your suspicions about use, the datum lines were almost completely worn away, and was very hard to set, even though it was super accurate (0.0001" datum settings) giving 0.0002" accuracy down a bore.

It was a semi automatic one, with the stop bar being used, the head stopped turning on the outside and you fed the tool one way or another by turning a little key that you inserted into the key slot in the side.

I gave it to a friend of mine and he was quite happy using it, he had better eyesight than myself.

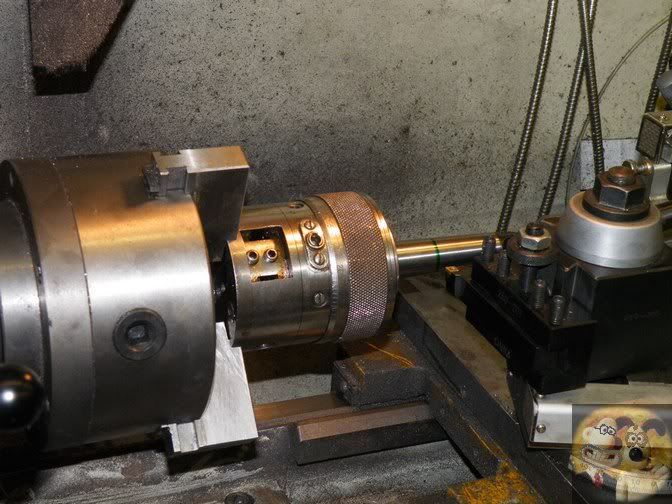

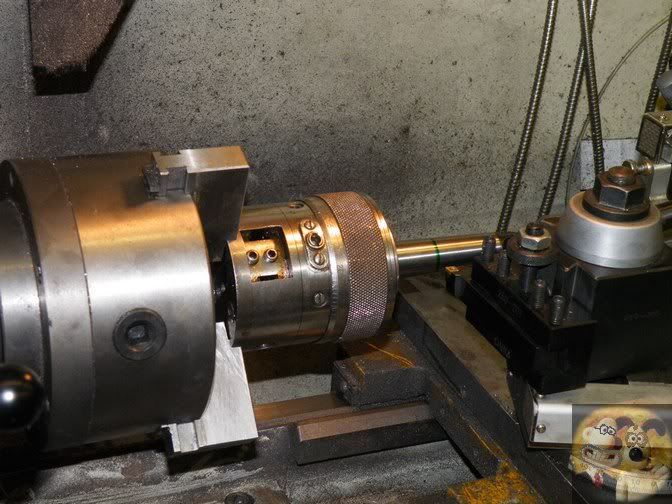

Straightening out the arbor by turning the 3MT down to a parallel 1/2" arbor while the head was held in accurately bored soft jaws..

John

A few years ago I bought a boring head second hand that did everything that mine now does, but the mounting spindle was bent. I paid 35bucks for it and was repaired in about an hour, but like your suspicions about use, the datum lines were almost completely worn away, and was very hard to set, even though it was super accurate (0.0001" datum settings) giving 0.0002" accuracy down a bore.

It was a semi automatic one, with the stop bar being used, the head stopped turning on the outside and you fed the tool one way or another by turning a little key that you inserted into the key slot in the side.

I gave it to a friend of mine and he was quite happy using it, he had better eyesight than myself.

Straightening out the arbor by turning the 3MT down to a parallel 1/2" arbor while the head was held in accurately bored soft jaws..

John

Last edited: