Naiveambition

Well-Known Member

- Joined

- May 15, 2012

- Messages

- 369

- Reaction score

- 95

Well after all my woes building a boring head, my trusty

pawn shop snooper/ brother in law came and dropped a narex boring facing head in my lap.

came and dropped a narex boring facing head in my lap.  He had mentioned it to me a couple weeks ago and with a Google search revealed they are quite expensive. So his initial plan was to make a profit. So he shows it to me. Like I'm gonna turn it down right

He had mentioned it to me a couple weeks ago and with a Google search revealed they are quite expensive. So his initial plan was to make a profit. So he shows it to me. Like I'm gonna turn it down right :rant: I wanted one but was focusing on dro first. So started building the one some of you was helping me on, Now I'm hesitant to finish the small one since this pretty much takes care of all the boring I would ever need. May even just sell the small one. Only bad part is I don't have power downfeed yet to really bring out the narex.

:rant: I wanted one but was focusing on dro first. So started building the one some of you was helping me on, Now I'm hesitant to finish the small one since this pretty much takes care of all the boring I would ever need. May even just sell the small one. Only bad part is I don't have power downfeed yet to really bring out the narex.

Anyways the tool is a narex 36 or 1 3/8 auto boring, facing head. With the r8 shank. How 220$ lucky is that The 28 page Manual

The 28 page Manual  looks like it will cut tapers also? Trying to wrap my head around that one. Set looks new with one bit maybe used and one missing. Very nice set for 400$

looks like it will cut tapers also? Trying to wrap my head around that one. Set looks new with one bit maybe used and one missing. Very nice set for 400$

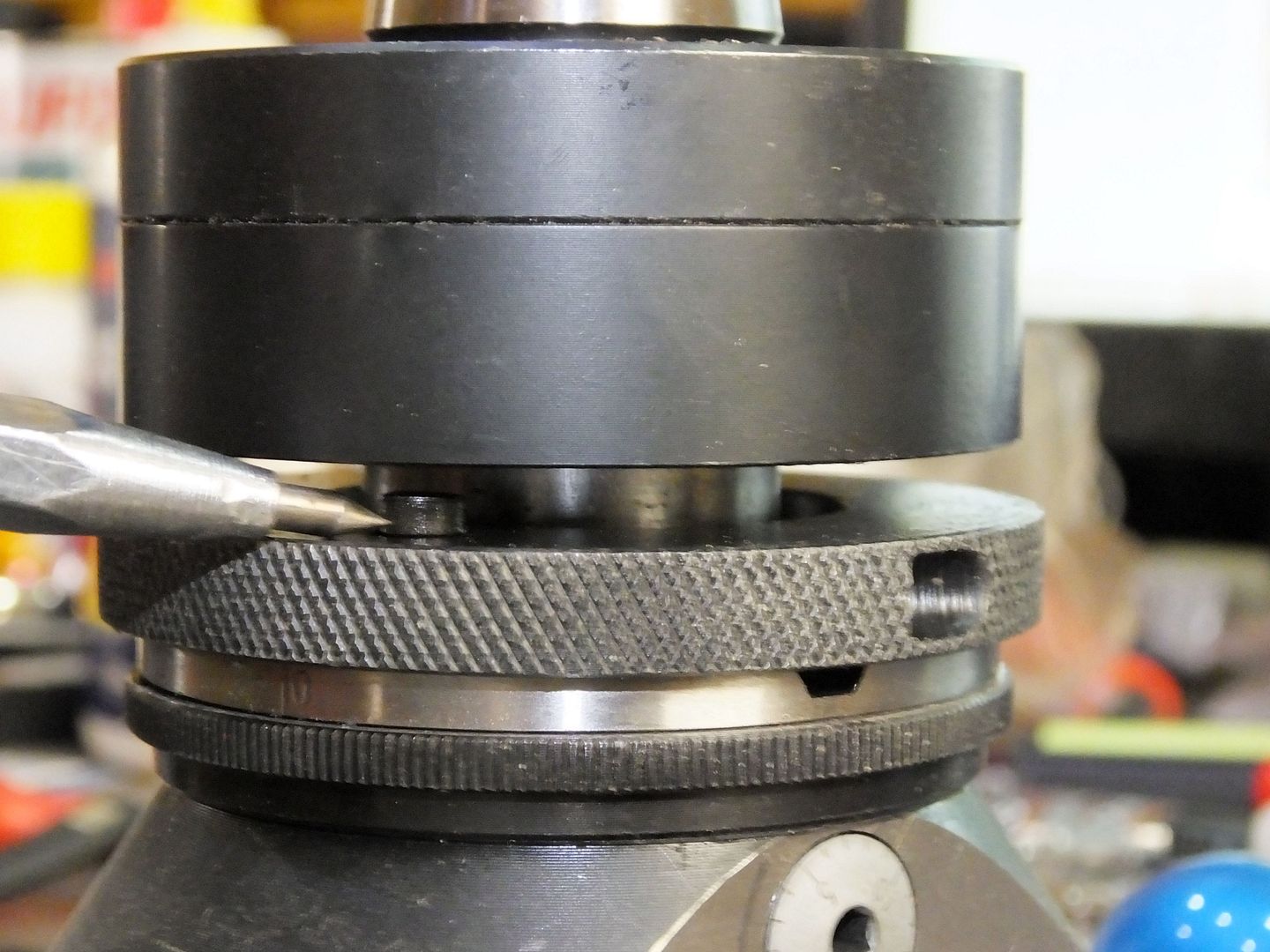

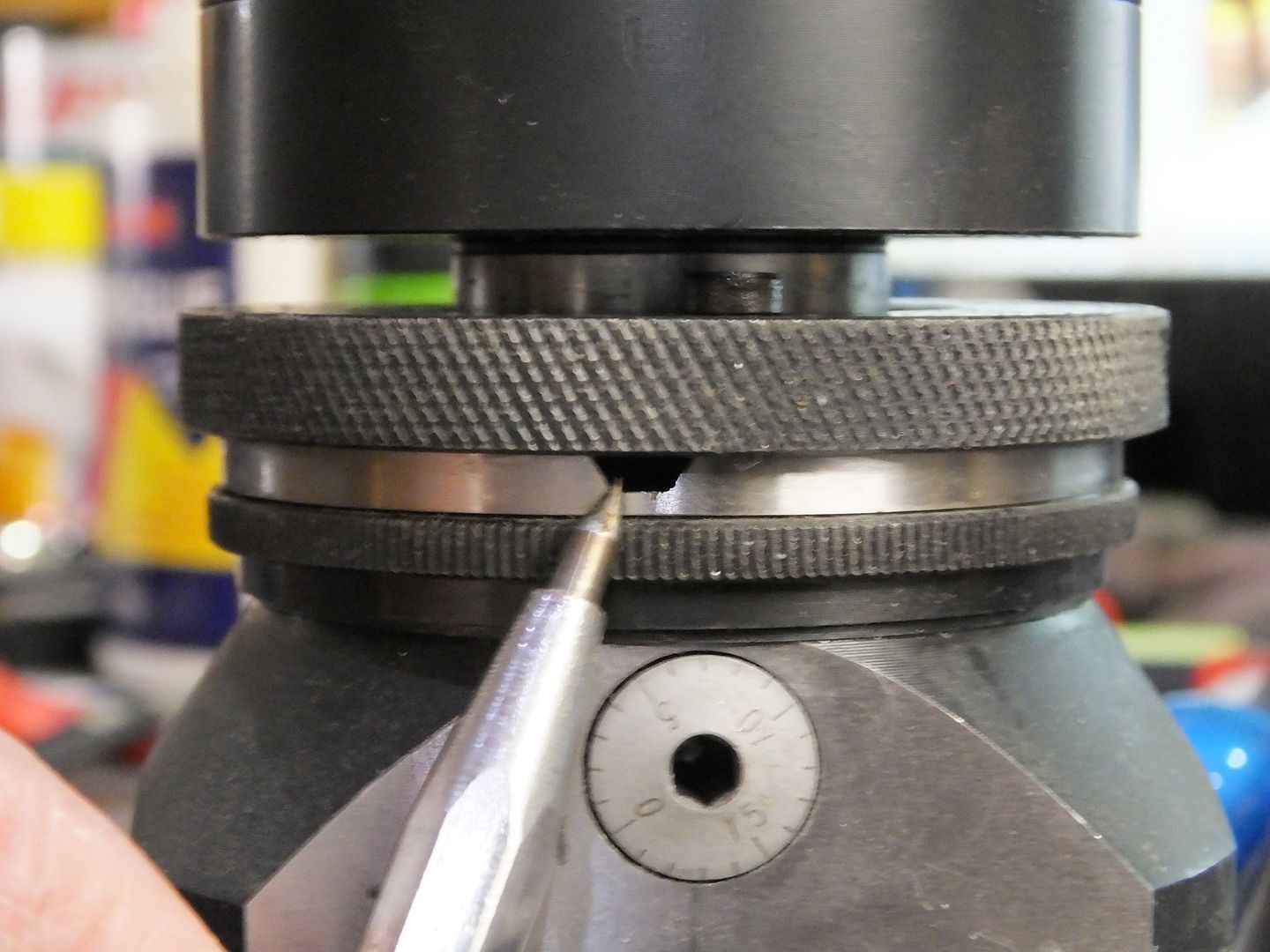

There is a brake ring on this an was wondering if someone can explain this please.

pawn shop snooper/ brother in law

Anyways the tool is a narex 36 or 1 3/8 auto boring, facing head. With the r8 shank. How 220$ lucky is that

There is a brake ring on this an was wondering if someone can explain this please.