Hello,

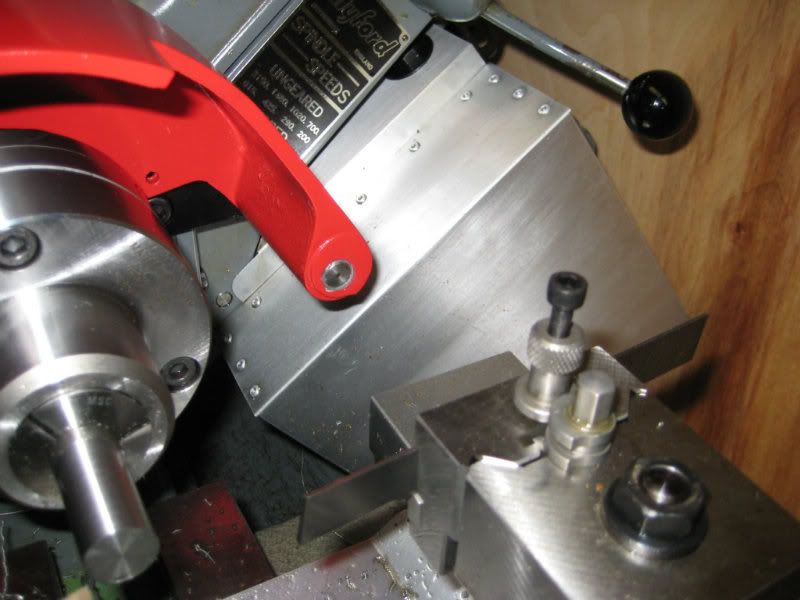

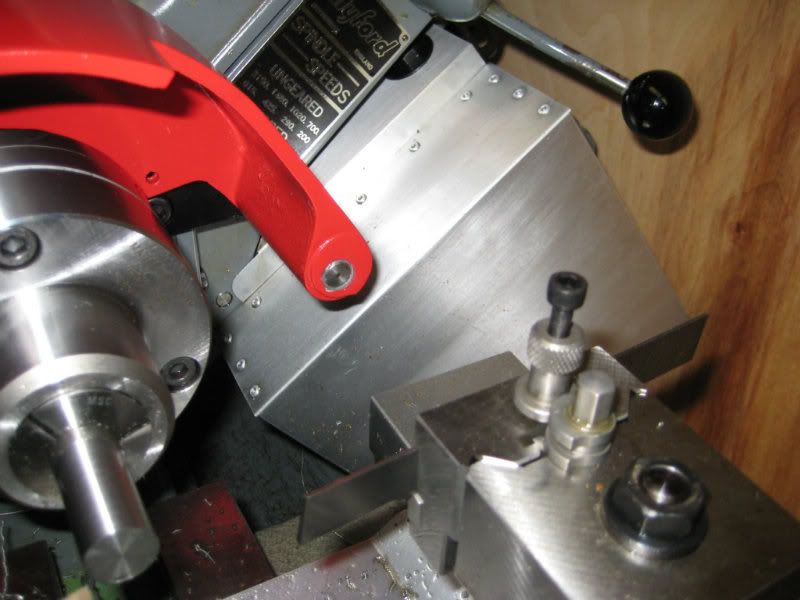

I recently finished several projects that were done in order to protect my Myford Super 7 lathe from the ingress of chips and swarf. First, was an aluminum cover to protect the motor. The cooling fan is right in line with the end of the spindle as is common on many bench-type lathes. It is a copy of the motor cover Myford used on their later model lathes. I just scaled a photo from a Model Engineer article that clearly showed the guard. It was a lot of work because it was all cut and bent by hand using a bench vise and cold-finished bar stock with clamps as bending fixtures. The parts were filed to the layout lines and tabs were provided for assembly with 'pop' rivets. The Myford motor cover isn't that expensive, it is the shipping cost of a rather large box to North America that made me decide to build my own.

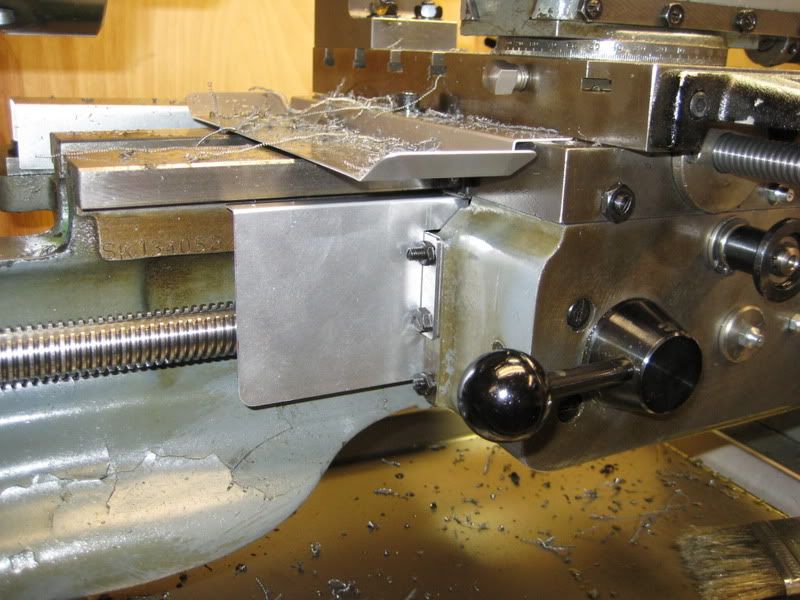

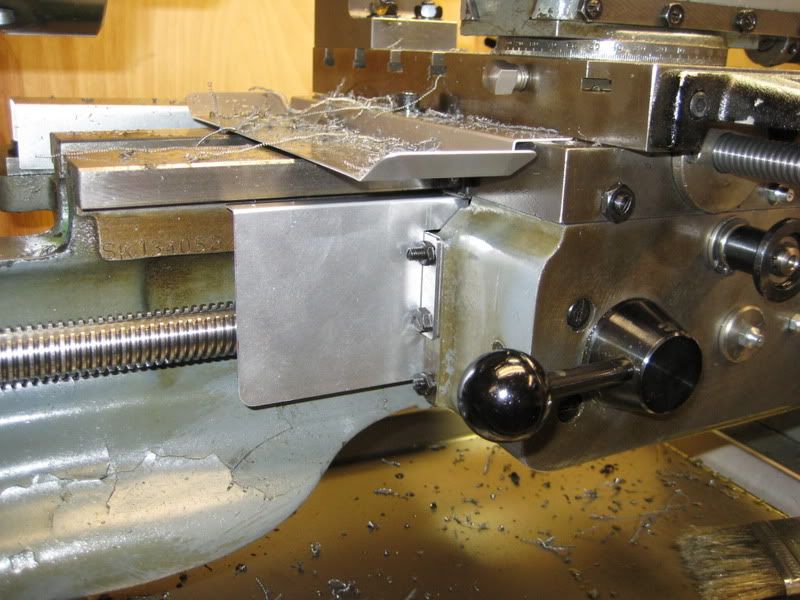

Next, is a part of a Hemingway Kit 'Swarf Guards' for the Myford Super 7 that is designed to replace the cast leadscrew chip guard and protects the otherwise exposed leadscrew and apron from chips. The 'kit' consists of drawings and material for this apron/leadscrew guard, a tailstock barrel wiper and a tailstock base wiper. I haven't got to the tailstock as yet. I felt the leadscrew/apron guard was the most important part to get in place first.

The kit provides sheet steel for this guard, but I made a test piece out of 1/32" thick 3003 aluminum to test my method of bending and it worked out perfectly, so I haven't seen the need to replace it with CRS. I just added a Micrometer Saddle Handwheel to the lathe and had the opportunity to remove the leadscrew and apron from my lathe as part of the installation process. I was very pleased to see how well this guard has done in keeping chips out of the apron and halfnuts. I can highly recommend this modification, which by the way, requires no modification to the lathe other than the removal of the cast leadscrew chip guard. It is attached via the halfnut gib setscrews and locknuts which secure the original cast guard.

http://www.hemingwaykits.com/acatalog/Swarf_Guards___Myford_Super_7.html

Last, are a pair of swarf trays that were inspired by an article by Guy Lautard in early 1980's of The Home Shop Machinist magazine and subsequently reprinted in 'PROJECTS One' titled: 'Swarf Trays for the Myford Series 7 Lathes'. The one in this photo is the shorter of the two that I made that is used for my 6" diameter four-jaw chuck. The other one, which is not shown, is similar but wider to use with the 4" diameter chucks that I have. They are attached using the mounting location for the follow rest on the lathe's saddle with one screw.

In this photo you can see how the swarf tray and the leadscrew/apron chip guard work in concert to keep the chips that come off of the tool out from where they shouldn't be, especially out from under the front way wiper which is well protected underneath the swarf tray. It also makes clean-up so much easier and faster.

This is my Myford Super 7 lathe that I am the proud third owner/caretaker of. It was purchased in 1978 by a clockmaker hobbyist who took great care of it and used it lightly. The person I bought it from was another clockmaker who never set it up and had stored it in his climate controlled workshop for many years. He had a Shaublin that he purchased new and I guess just never got around to the Myford. It has a hardened bed and most accessories including the indexing & dividing head. It also came with every piece of original documentation including the manuals, sales brochures, accessory flyer's, receipts and even the original purchaser's personal correspondence with Myford. We pay a premium for these machines in North America because there just aren't that many that come up for sale each year. I had to drive to Florida to pick it up and learned what heatstroke is while disassembling and loading the lathe into my truck in high humidity, high 90 degree temperatures. But that is another story. That was when I realized that I am not a young man anymore and as the saying goes..."If I had known that I was going to live this long, I would have taken better care of myself".

It is a sweet lathe that is an absolute joy to use and these additions should help to protect and preserve it.

Regards,

Mike

I recently finished several projects that were done in order to protect my Myford Super 7 lathe from the ingress of chips and swarf. First, was an aluminum cover to protect the motor. The cooling fan is right in line with the end of the spindle as is common on many bench-type lathes. It is a copy of the motor cover Myford used on their later model lathes. I just scaled a photo from a Model Engineer article that clearly showed the guard. It was a lot of work because it was all cut and bent by hand using a bench vise and cold-finished bar stock with clamps as bending fixtures. The parts were filed to the layout lines and tabs were provided for assembly with 'pop' rivets. The Myford motor cover isn't that expensive, it is the shipping cost of a rather large box to North America that made me decide to build my own.

Next, is a part of a Hemingway Kit 'Swarf Guards' for the Myford Super 7 that is designed to replace the cast leadscrew chip guard and protects the otherwise exposed leadscrew and apron from chips. The 'kit' consists of drawings and material for this apron/leadscrew guard, a tailstock barrel wiper and a tailstock base wiper. I haven't got to the tailstock as yet. I felt the leadscrew/apron guard was the most important part to get in place first.

The kit provides sheet steel for this guard, but I made a test piece out of 1/32" thick 3003 aluminum to test my method of bending and it worked out perfectly, so I haven't seen the need to replace it with CRS. I just added a Micrometer Saddle Handwheel to the lathe and had the opportunity to remove the leadscrew and apron from my lathe as part of the installation process. I was very pleased to see how well this guard has done in keeping chips out of the apron and halfnuts. I can highly recommend this modification, which by the way, requires no modification to the lathe other than the removal of the cast leadscrew chip guard. It is attached via the halfnut gib setscrews and locknuts which secure the original cast guard.

http://www.hemingwaykits.com/acatalog/Swarf_Guards___Myford_Super_7.html

Last, are a pair of swarf trays that were inspired by an article by Guy Lautard in early 1980's of The Home Shop Machinist magazine and subsequently reprinted in 'PROJECTS One' titled: 'Swarf Trays for the Myford Series 7 Lathes'. The one in this photo is the shorter of the two that I made that is used for my 6" diameter four-jaw chuck. The other one, which is not shown, is similar but wider to use with the 4" diameter chucks that I have. They are attached using the mounting location for the follow rest on the lathe's saddle with one screw.

In this photo you can see how the swarf tray and the leadscrew/apron chip guard work in concert to keep the chips that come off of the tool out from where they shouldn't be, especially out from under the front way wiper which is well protected underneath the swarf tray. It also makes clean-up so much easier and faster.

This is my Myford Super 7 lathe that I am the proud third owner/caretaker of. It was purchased in 1978 by a clockmaker hobbyist who took great care of it and used it lightly. The person I bought it from was another clockmaker who never set it up and had stored it in his climate controlled workshop for many years. He had a Shaublin that he purchased new and I guess just never got around to the Myford. It has a hardened bed and most accessories including the indexing & dividing head. It also came with every piece of original documentation including the manuals, sales brochures, accessory flyer's, receipts and even the original purchaser's personal correspondence with Myford. We pay a premium for these machines in North America because there just aren't that many that come up for sale each year. I had to drive to Florida to pick it up and learned what heatstroke is while disassembling and loading the lathe into my truck in high humidity, high 90 degree temperatures. But that is another story. That was when I realized that I am not a young man anymore and as the saying goes..."If I had known that I was going to live this long, I would have taken better care of myself".

It is a sweet lathe that is an absolute joy to use and these additions should help to protect and preserve it.

Regards,

Mike