Shopguy posted his Surface Grinder for sale on the HMEM board. I inquired about it and the price was right, all I had to do was to drive there to help him get it out of his house that he sold and needed to be out by the following week. Well I had the time to go for a quick trip to Alberta some 11 hours of driving and enough time to take it apart the first night. The night before leaving I had to take my sons welding machine out of his truck a one ton dully Dodge.

I got up at 3:30 AM to head out for the long drive. I stopped at Tim Hortons for a couple of coffees and sandwiches for the trip. All I had to stop for was a little leg stretching and nature calls.

I hit the 401 highway about 3:50 AM, hit the cruse at 110 KM and go. When I get to hope BC it starts to snow oh no this is not good. It snowed all the way to Golden BC then stopped. It seemed like I was at the head of the storm as there was not much on the ground all the way.

I was surprised at how much the snow depths differed in each areas where.

http://s572.photobucket.com/albums/ss166/PhillyVa/?action=view¤t=IMG_0252.jpg

In the Canadian Rockies the grass is poking out and in other areas 4 or 5 feet.

There seemed to be more in the foothills.

There is a stark beauty to the foothills of Alberta.

I hook-up with Ernie at about 3:30 PM Alberta time. We go over to the sold house and start to disassemble the grinder. We get it all apart and its dark outside the decision is made to load in the morning.

The pictures of moving the grinder up and on the truck which took a few hours, go here

http://s605.photobucket.com/albums/...RFACE GRINDER MOVE/?action=view¤t=1.jpg http://s605.photobucket.com/albums/...tion-view¤t=SURFACEGRINDERMOVEPICS2.jpg http://s605.photobucket.com/albums/...tion=view¤t=SURFACEGRINDERMOVEPICS3.jpg http://s605.photobucket.com/albums/...tion-view¤t=SURFACEGRINDERMOVEPICS4.jpg http://s605.photobucket.com/albums/...tion=view¤t=SURFACEGRINDERMOVEPICS5.jpg http://s605.photobucket.com/albums/...tion-view¤t=SURFACEGRINDERMOVEPICS6.jpg http://s605.photobucket.com/albums/...tion=view¤t=SURFACEGRINDERMOVEPICS7.jpg

It only took me 10 ½ hours to get home. I think its all down hill from Alberta. Its 3300 ft where Ernie lives. Thats only a theory of mine, the sunny sky and dry roads and a Dodge diesel just might have something to do with it.

The unloading only took me about 15-20 min. I had an I beam and a one ton chain bloke in my garage simple safe too easy I love it.

Together

OK now its all together time for a test. Oh-Oh what are the controls what does what. I send Ernie an email and he sends me a reply of whats what. OK good to go or so I thought. Every thing works by hand but, I cant make go on automatic feed.

Now I have to take it apart again (Im sorry I didnt take pics through this part but my hands are all greasy and black my wife would choke me if I messed it up.

Every thing looks in order but one place I found had some shinny spots. I scratch my noodle and think there must be some info on the web. I go online and look up the patent office under Brown & Sharpe I find this page 1 of 10 has all the info I need. Its not the same but the idea is close enough for me.

http://www.google.com/patents?id=oj...a=X&oi=book_result&resnum=3&ct=result#PPA3,M1

Im looking at part #104

I had a chunk of brass for a quick temporary fix and trial, thinking that brass is soft and wont do too much damage. It works YEA!

Here are some of the parts that clued me in

Now to make the part. I had a chunk of drill rod to turn down.

Testing the part

Now its parted off and slipped in position.

Another view

Drilling it out

Finished

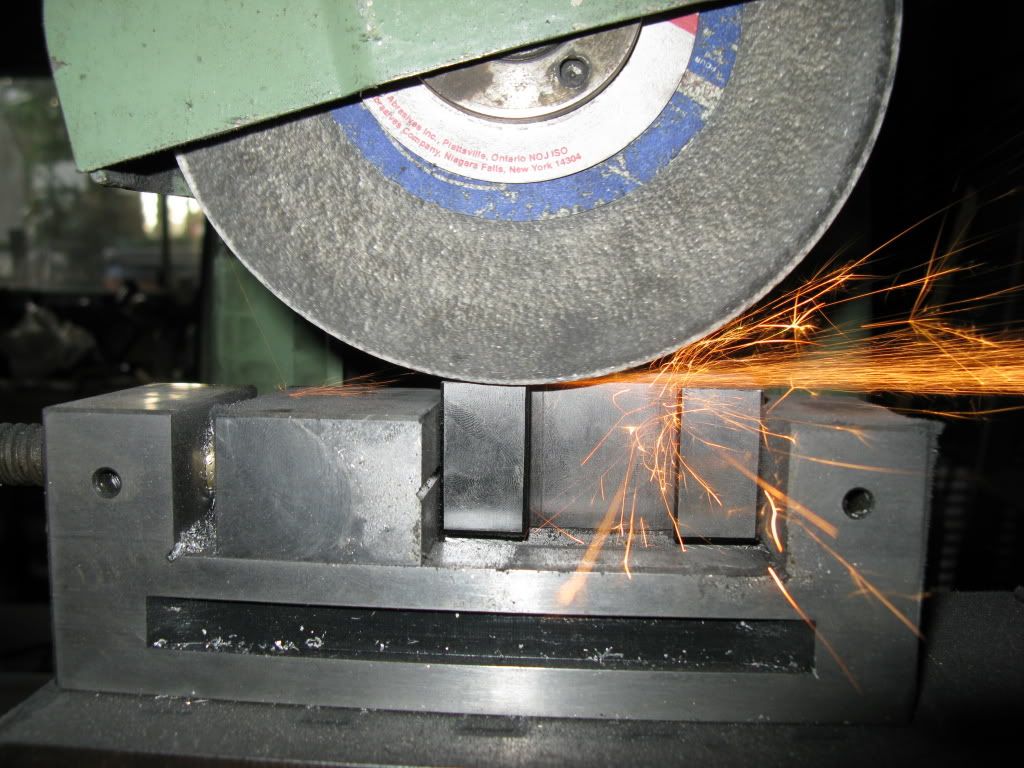

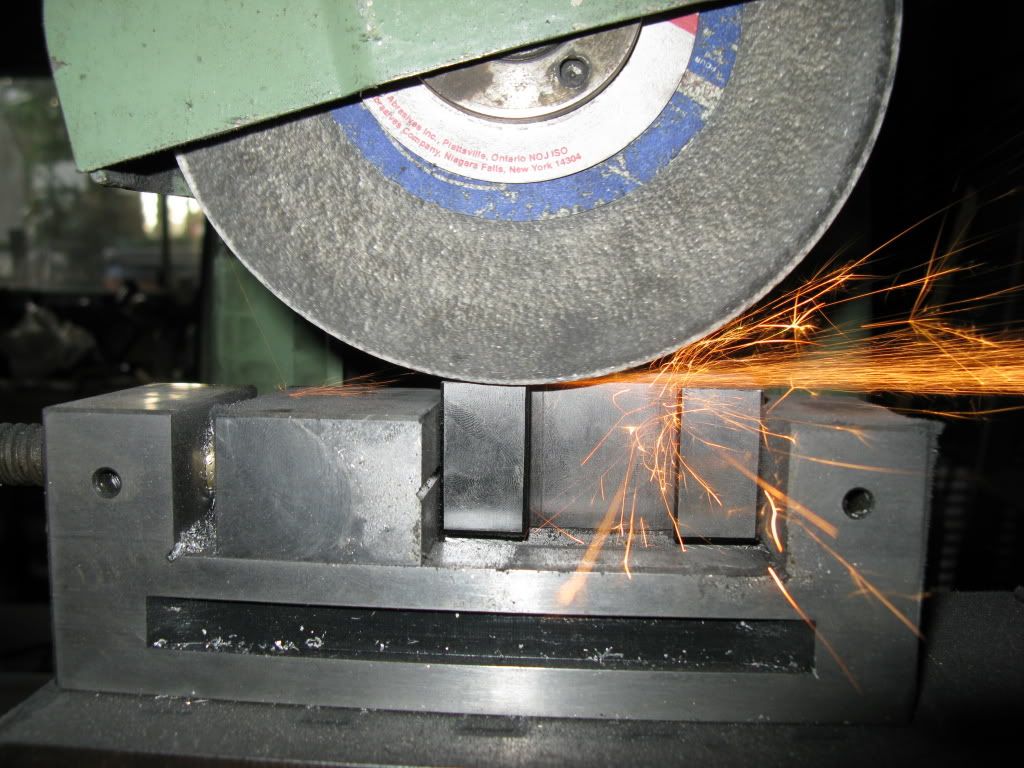

Now in action

First job complete.

The top tool holder was done on a friends milling machine. It was the only one that was soft enough to cut with an end mill nicely. Now I have to buy him a new end mill. The bottom tool holder was done on the surface grinder all nice and shinny.

Well I thought that this was over but, when I helped my son put his welder back in his truck I moved a chain and found the missing part under it. The picture will show the differences.

Old part 0.791 dia. New part 0.785 dia.

Old part 1.965 length New part 1.805 length

Not bad for guesses. The old part has some flat spots. I will make another 2 parts the right size and keep these for spares.

Just to take it a step further I could call Brown & Sharpe to get a new part from them. For a price of (just guessing) $80.00. This has been an interesting exercise and took a bit of time.

Ill now thank Ernie and Carole for their hospitality. Ernies trying to set up his shop now in the new place. He has some interesting engines I like the Tiny he built with a penny in the flywheel maybe hell post a picture one day. OK thats enough I should go and make some nice shinny parts.

Regards and a happy

Philly

I got up at 3:30 AM to head out for the long drive. I stopped at Tim Hortons for a couple of coffees and sandwiches for the trip. All I had to stop for was a little leg stretching and nature calls.

I hit the 401 highway about 3:50 AM, hit the cruse at 110 KM and go. When I get to hope BC it starts to snow oh no this is not good. It snowed all the way to Golden BC then stopped. It seemed like I was at the head of the storm as there was not much on the ground all the way.

I was surprised at how much the snow depths differed in each areas where.

http://s572.photobucket.com/albums/ss166/PhillyVa/?action=view¤t=IMG_0252.jpg

In the Canadian Rockies the grass is poking out and in other areas 4 or 5 feet.

There seemed to be more in the foothills.

There is a stark beauty to the foothills of Alberta.

I hook-up with Ernie at about 3:30 PM Alberta time. We go over to the sold house and start to disassemble the grinder. We get it all apart and its dark outside the decision is made to load in the morning.

The pictures of moving the grinder up and on the truck which took a few hours, go here

http://s605.photobucket.com/albums/...RFACE GRINDER MOVE/?action=view¤t=1.jpg http://s605.photobucket.com/albums/...tion-view¤t=SURFACEGRINDERMOVEPICS2.jpg http://s605.photobucket.com/albums/...tion=view¤t=SURFACEGRINDERMOVEPICS3.jpg http://s605.photobucket.com/albums/...tion-view¤t=SURFACEGRINDERMOVEPICS4.jpg http://s605.photobucket.com/albums/...tion=view¤t=SURFACEGRINDERMOVEPICS5.jpg http://s605.photobucket.com/albums/...tion-view¤t=SURFACEGRINDERMOVEPICS6.jpg http://s605.photobucket.com/albums/...tion=view¤t=SURFACEGRINDERMOVEPICS7.jpg

It only took me 10 ½ hours to get home. I think its all down hill from Alberta. Its 3300 ft where Ernie lives. Thats only a theory of mine, the sunny sky and dry roads and a Dodge diesel just might have something to do with it.

The unloading only took me about 15-20 min. I had an I beam and a one ton chain bloke in my garage simple safe too easy I love it.

Together

OK now its all together time for a test. Oh-Oh what are the controls what does what. I send Ernie an email and he sends me a reply of whats what. OK good to go or so I thought. Every thing works by hand but, I cant make go on automatic feed.

Now I have to take it apart again (Im sorry I didnt take pics through this part but my hands are all greasy and black my wife would choke me if I messed it up.

Every thing looks in order but one place I found had some shinny spots. I scratch my noodle and think there must be some info on the web. I go online and look up the patent office under Brown & Sharpe I find this page 1 of 10 has all the info I need. Its not the same but the idea is close enough for me.

http://www.google.com/patents?id=oj...a=X&oi=book_result&resnum=3&ct=result#PPA3,M1

Im looking at part #104

I had a chunk of brass for a quick temporary fix and trial, thinking that brass is soft and wont do too much damage. It works YEA!

Here are some of the parts that clued me in

Now to make the part. I had a chunk of drill rod to turn down.

Testing the part

Now its parted off and slipped in position.

Another view

Drilling it out

Finished

Now in action

First job complete.

The top tool holder was done on a friends milling machine. It was the only one that was soft enough to cut with an end mill nicely. Now I have to buy him a new end mill. The bottom tool holder was done on the surface grinder all nice and shinny.

Well I thought that this was over but, when I helped my son put his welder back in his truck I moved a chain and found the missing part under it. The picture will show the differences.

Old part 0.791 dia. New part 0.785 dia.

Old part 1.965 length New part 1.805 length

Not bad for guesses. The old part has some flat spots. I will make another 2 parts the right size and keep these for spares.

Just to take it a step further I could call Brown & Sharpe to get a new part from them. For a price of (just guessing) $80.00. This has been an interesting exercise and took a bit of time.

Ill now thank Ernie and Carole for their hospitality. Ernies trying to set up his shop now in the new place. He has some interesting engines I like the Tiny he built with a penny in the flywheel maybe hell post a picture one day. OK thats enough I should go and make some nice shinny parts.

Regards and a happy

Philly