Hi Jeroen

Yeh, it needed another speed controler.

Thanks for the complement.

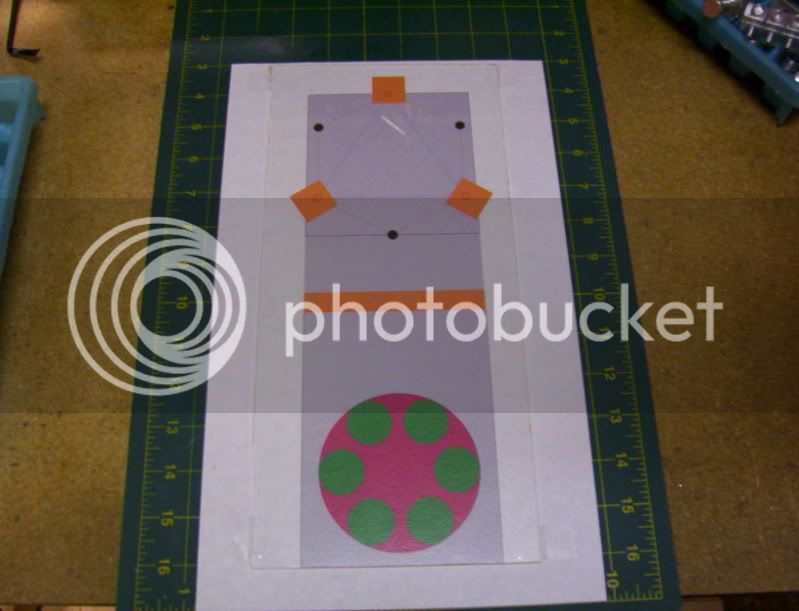

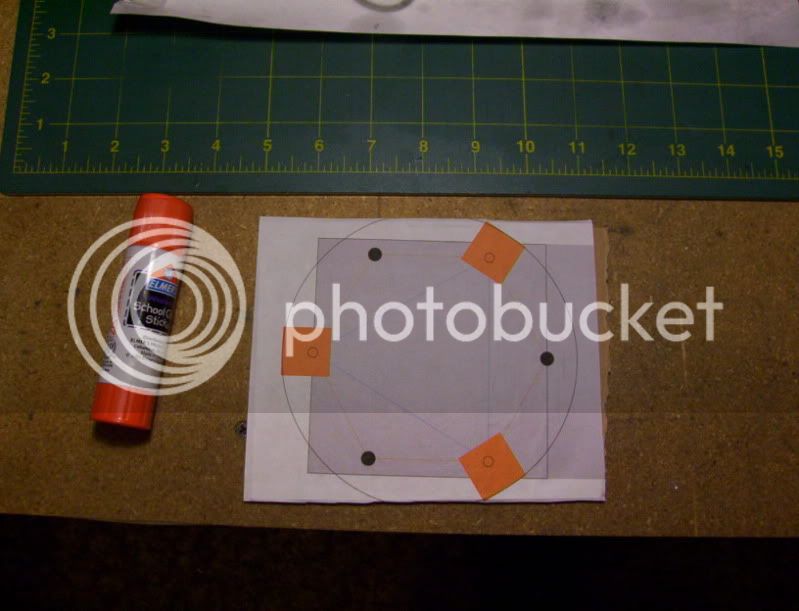

Nice thing about wooden jigs, there quicker and easier to make and once your done with them they can be discarded, easily.

-----------------------------------------------------------------------------------------------------------

Todays session was more about fixing mistakes.

I was making the roughed out spigots (square posts) too large, I made them 1/4" square to fit the larger formtool, for larger dia. tubing.

This project calls for smaller dia. tubing, so I was using the smaller formtool, on the mistakenly large square posts, and end up breaking the form tool, as well as messing up the workpiece.

So after some careful thinking, instead of making a new workpiece, I decided the best way to fix this would be to cut off both ruined square posts, and set it back up in the spin jig, drill for a plug, then remachine the plug to the proper square post size.

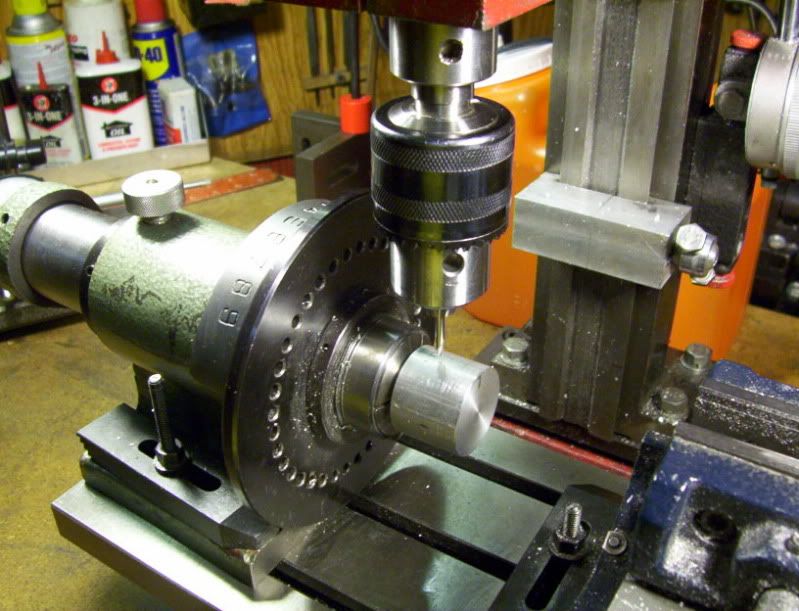

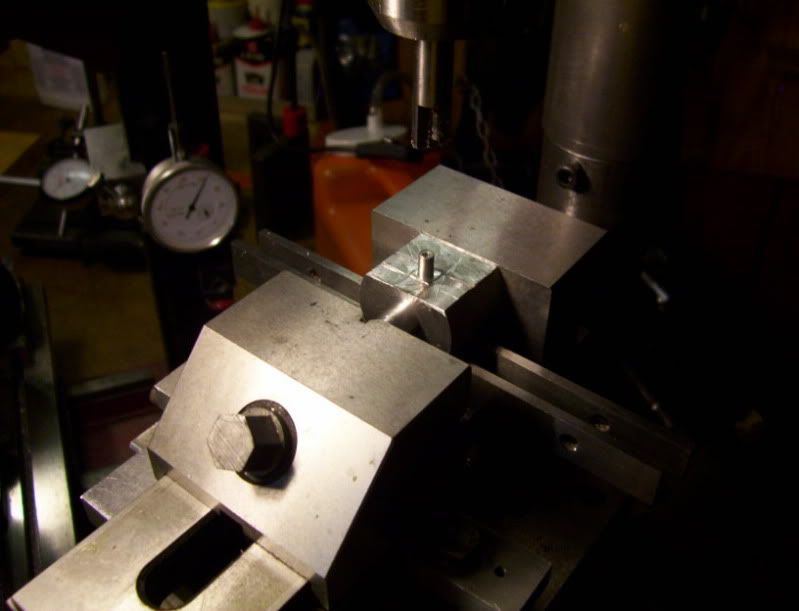

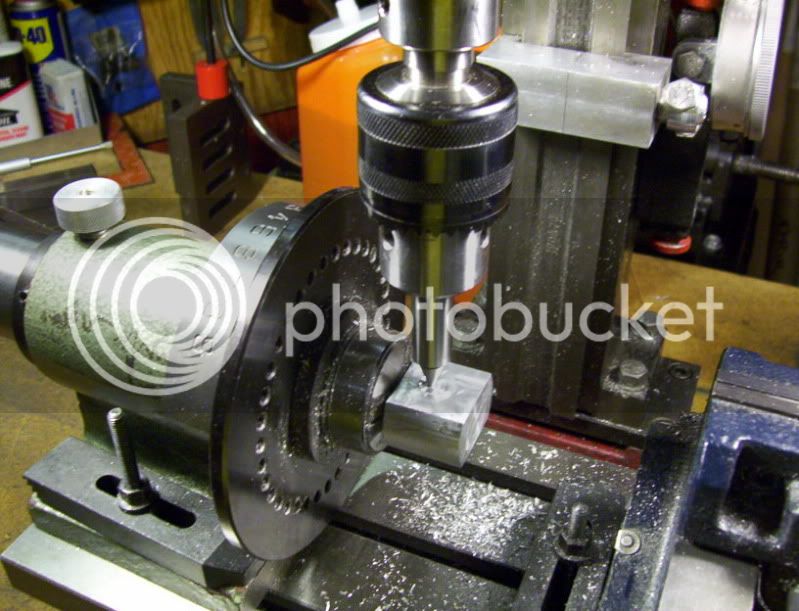

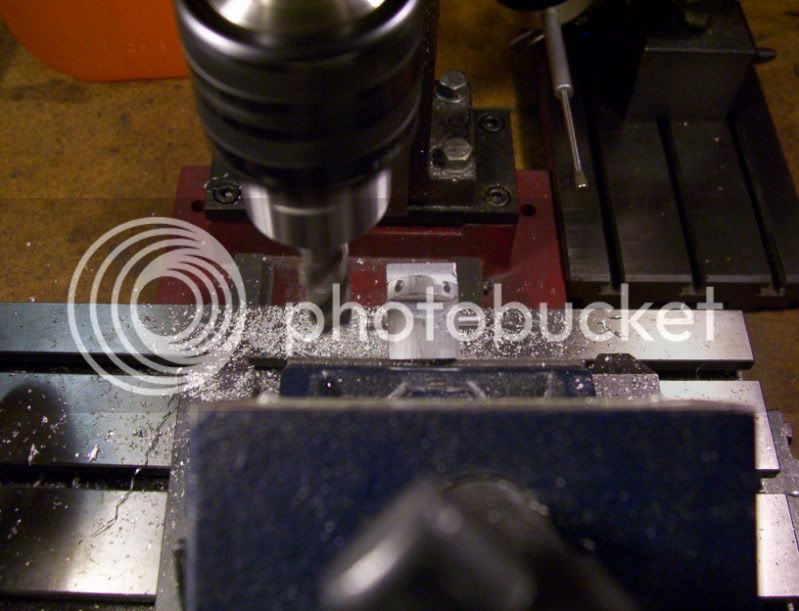

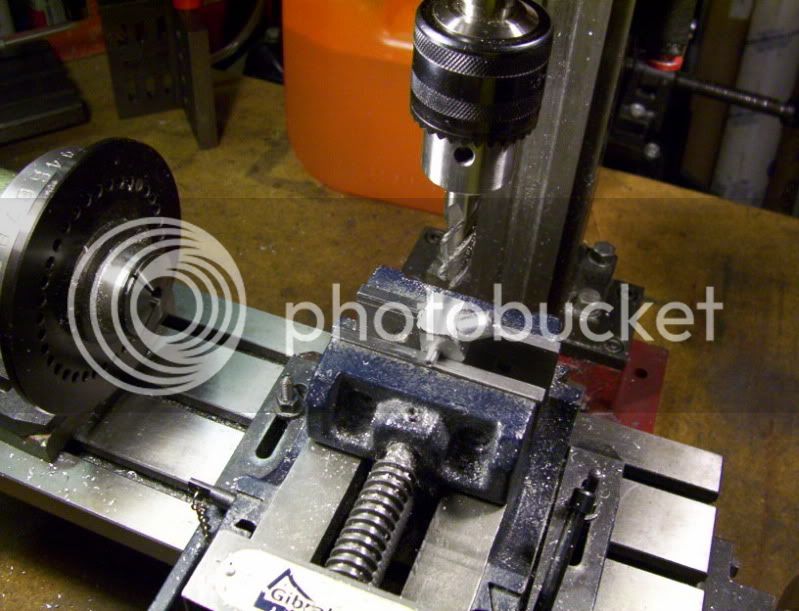

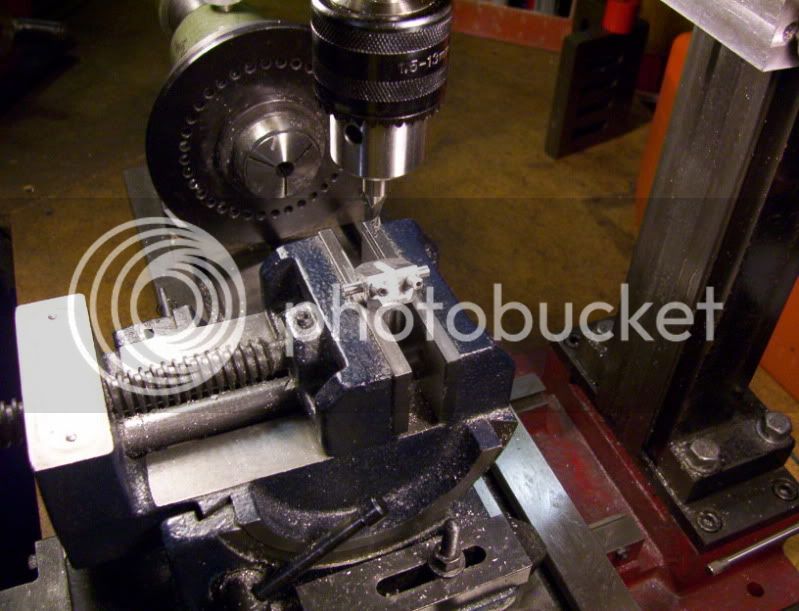

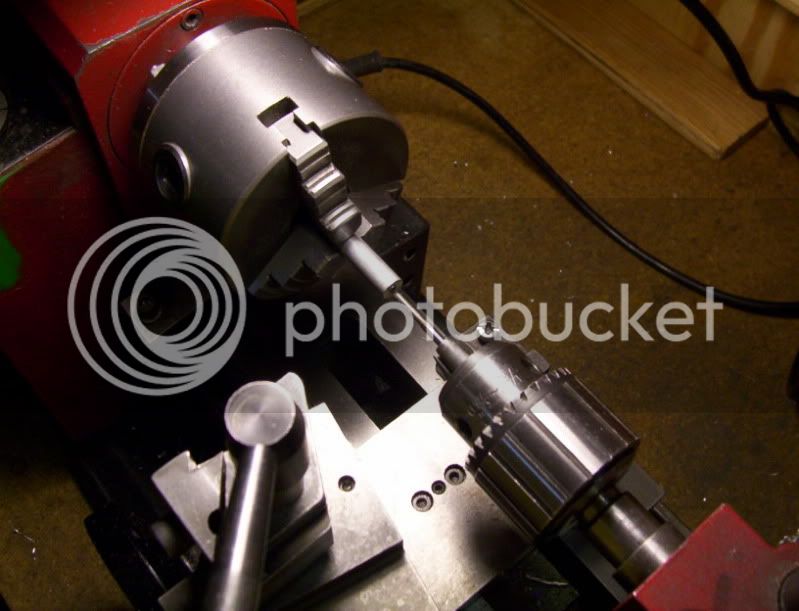

So first I turned the spin jig, to 90*,

by doing this I can reinsert the workpiece on the vertical, and use a square to line it up square to the table surface.

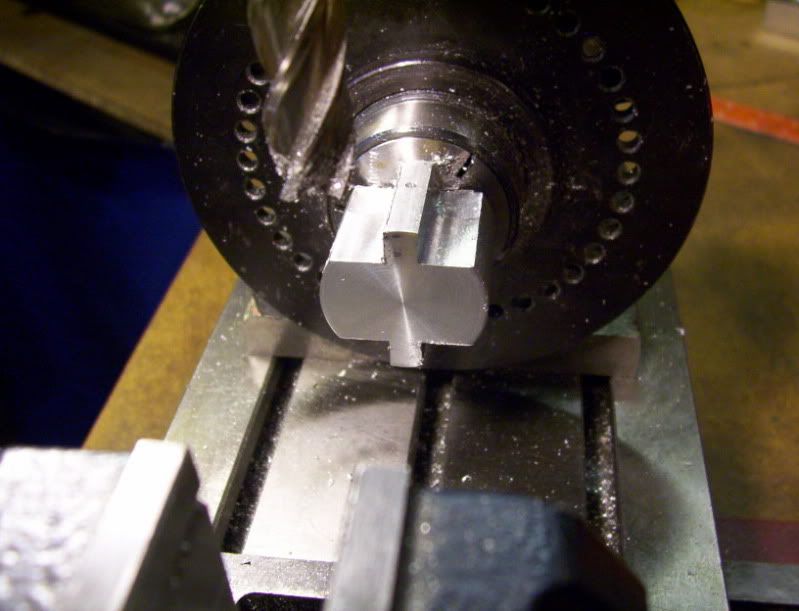

from there, I proceeded to machine off the one bad stud,

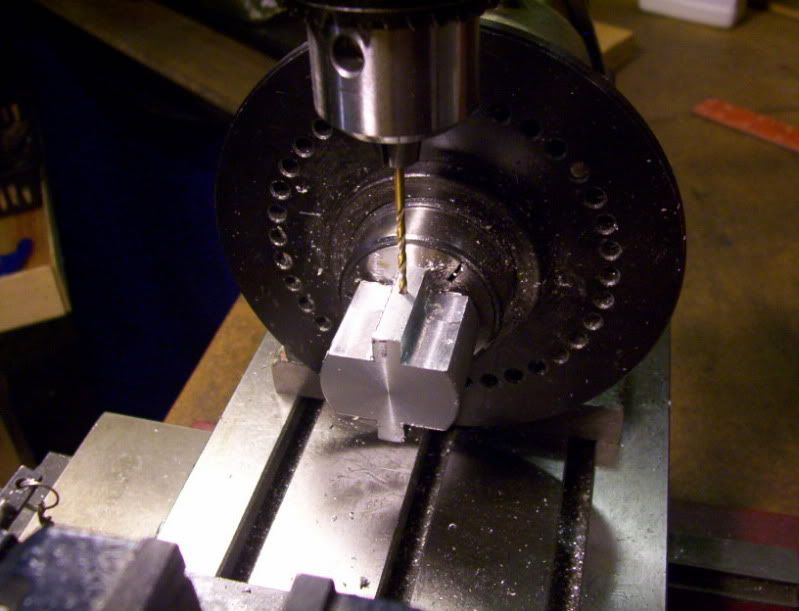

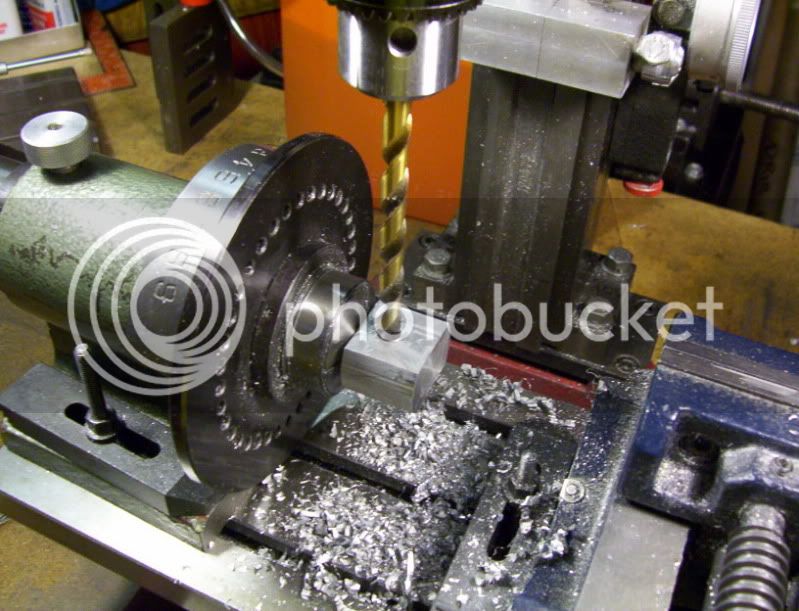

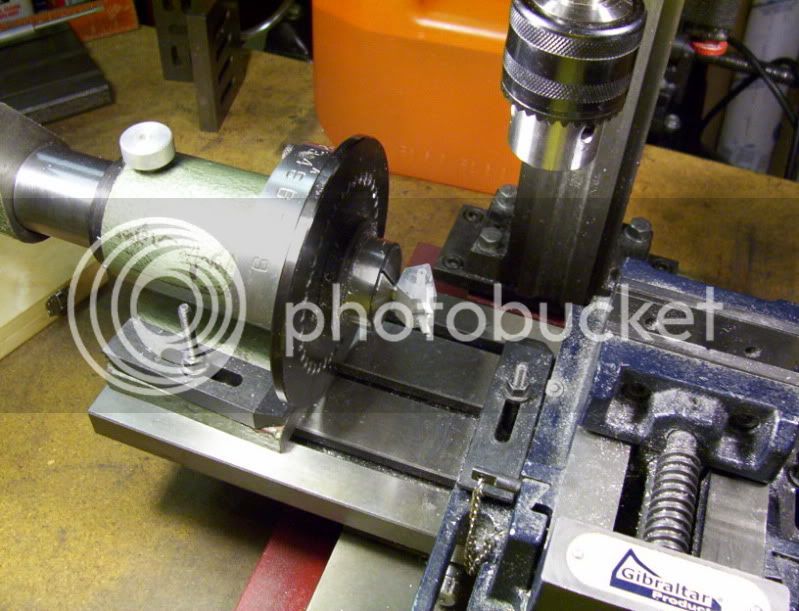

Then using a center finder I located the original drilled hole.

.

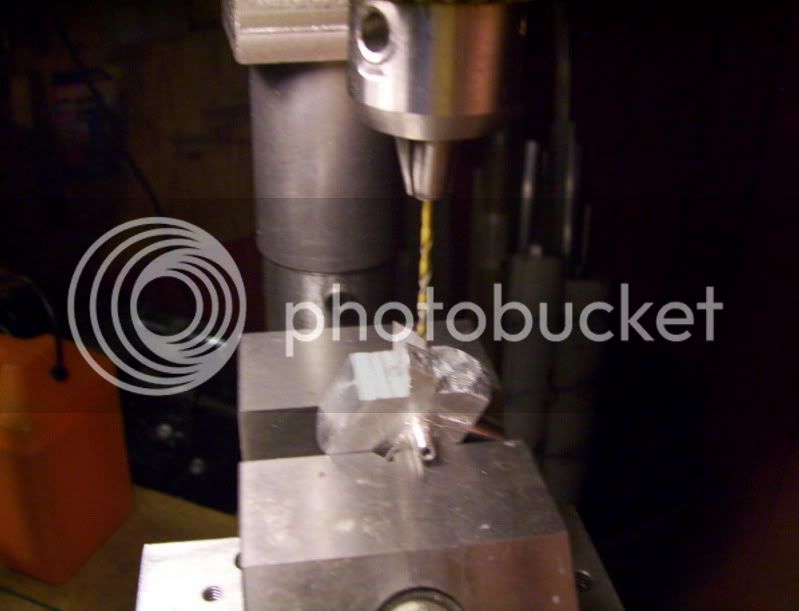

And used a 5/16" drill to make a thru hole.

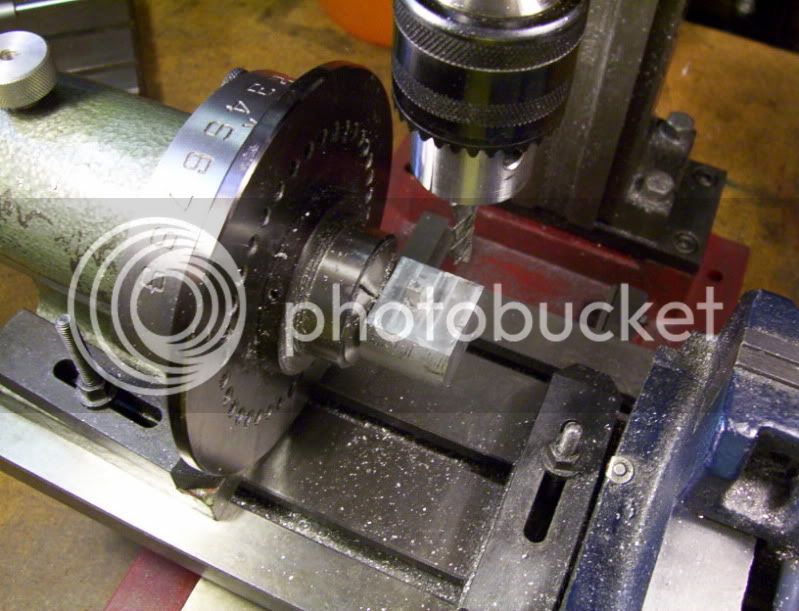

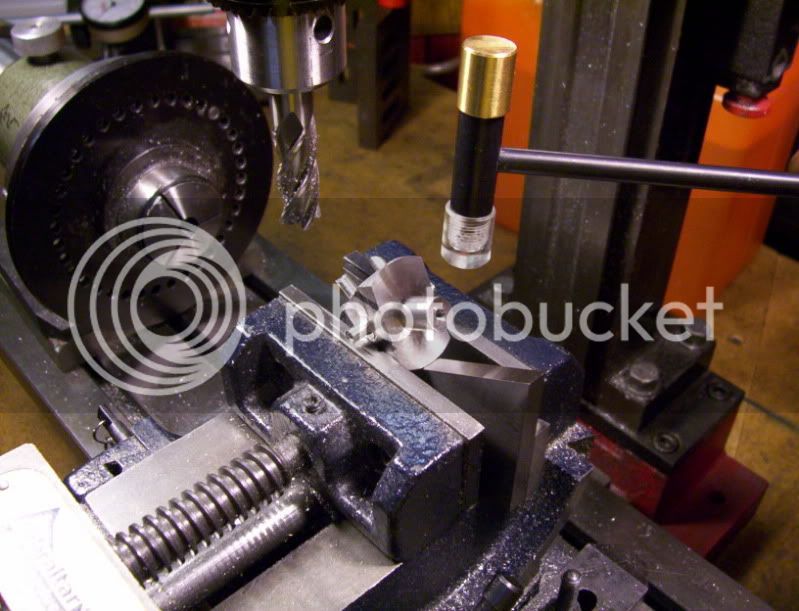

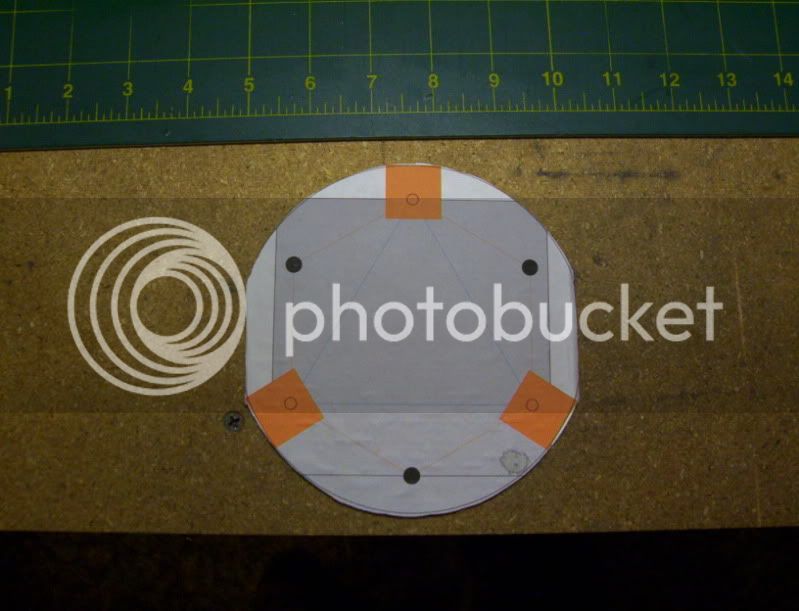

Then took a piece of 3/8" dia. dowle and machined it to the proper dia, to fit the drilled hole, leaving 1/4" in heigth left as a shoulder, to press fit into the workpiece.

While it was spinning in the lathe I took a file and set it on edge to make some ring grooves, that will be used for keying in for the loctite glue.

Pressed it in.

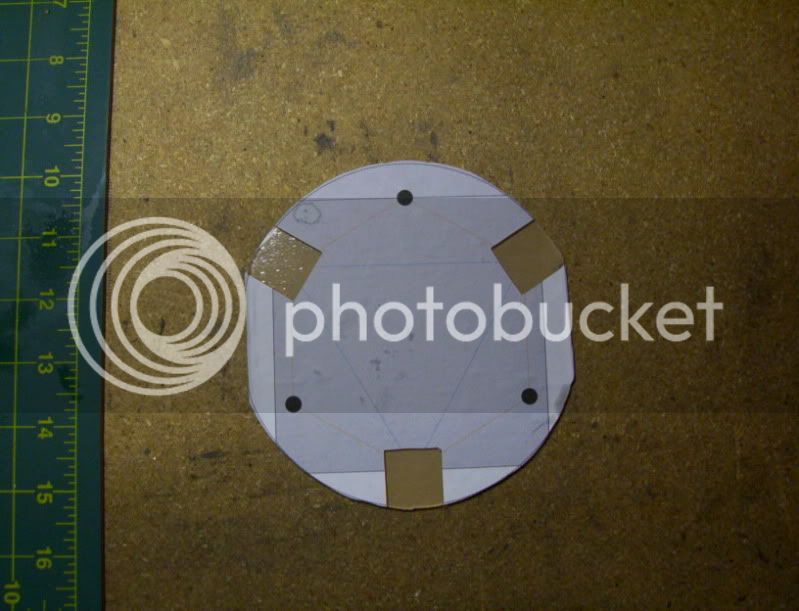

Then redrilled, and remachined to get the proper size square post.

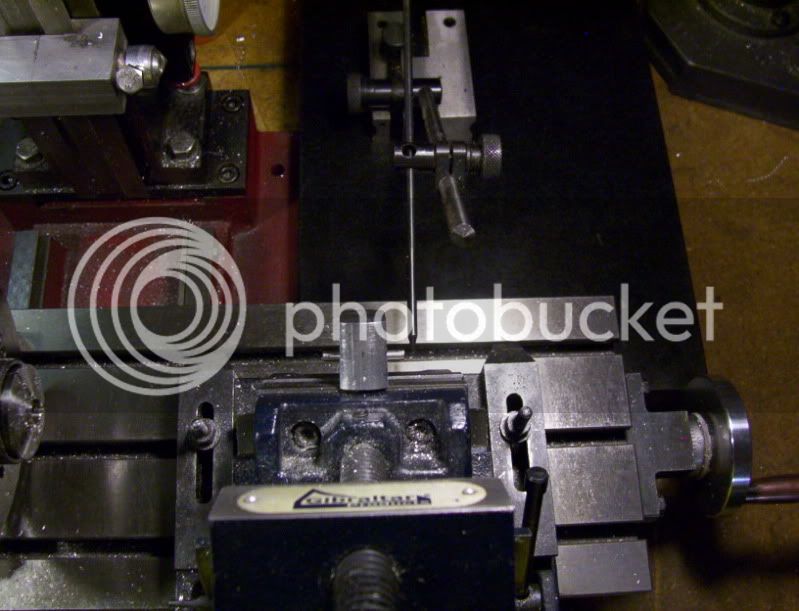

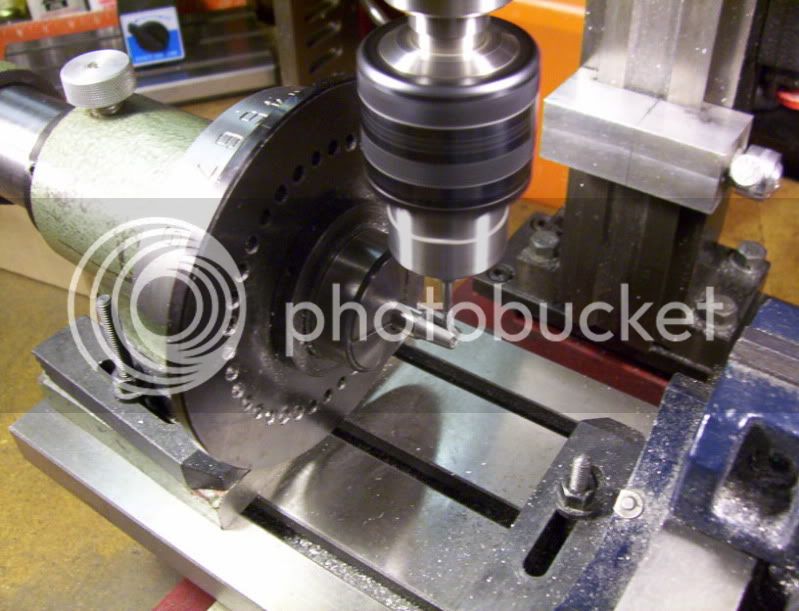

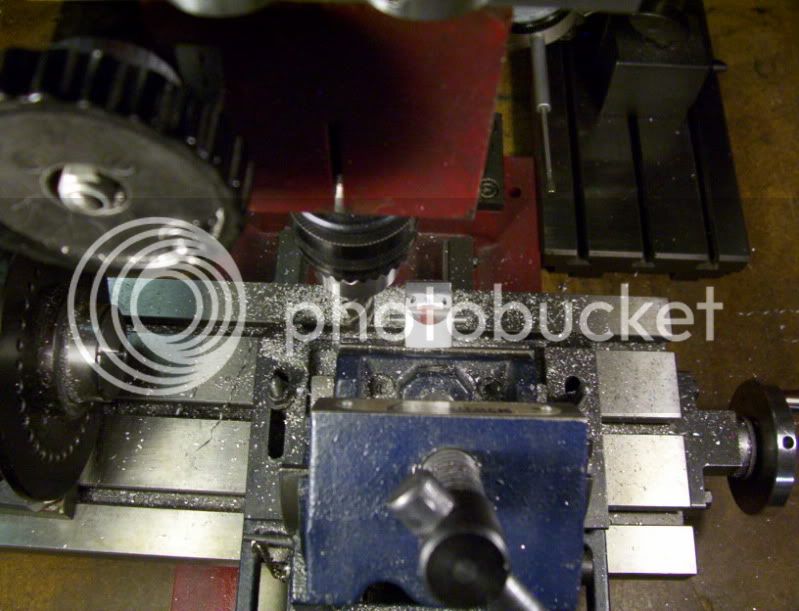

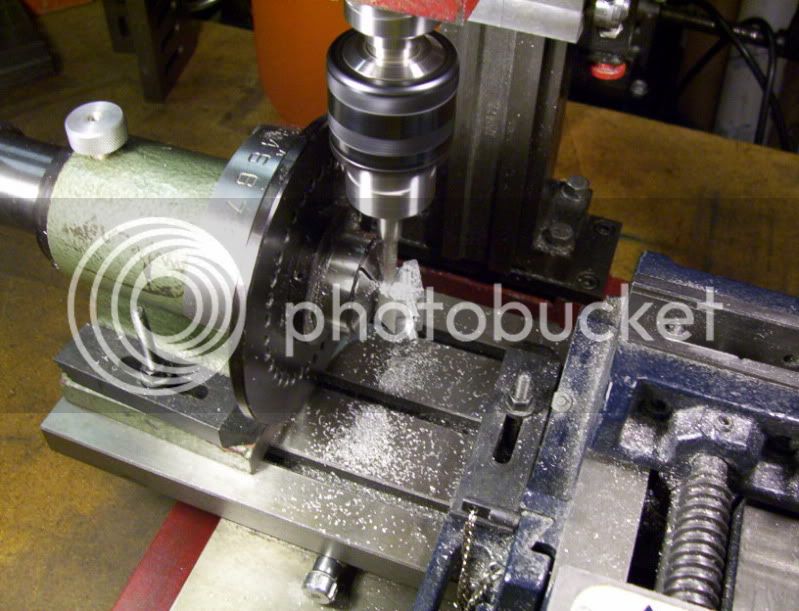

Ok now time to make a new formtool, however this time I'm making it more like a cutter/formtool,

by offsetting the endmill cut off center allows the endmill to cut a somewhat sharp edge on the tool.

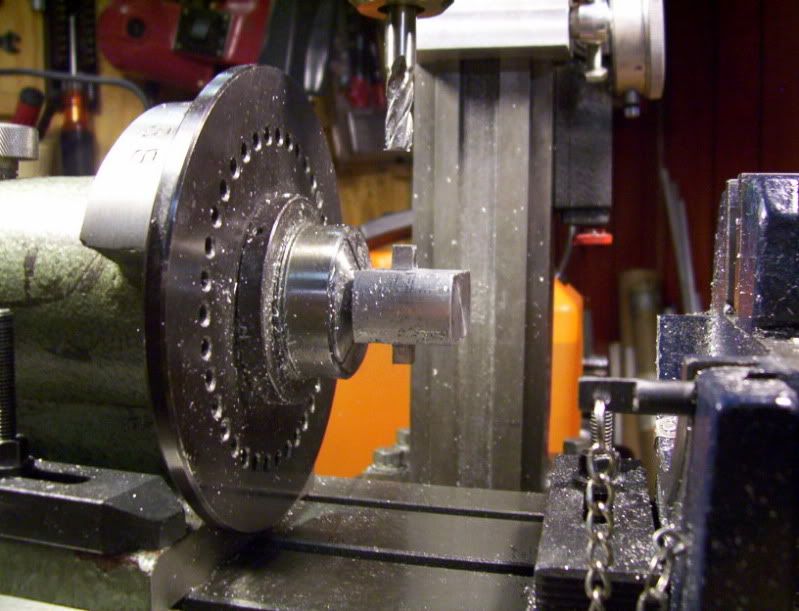

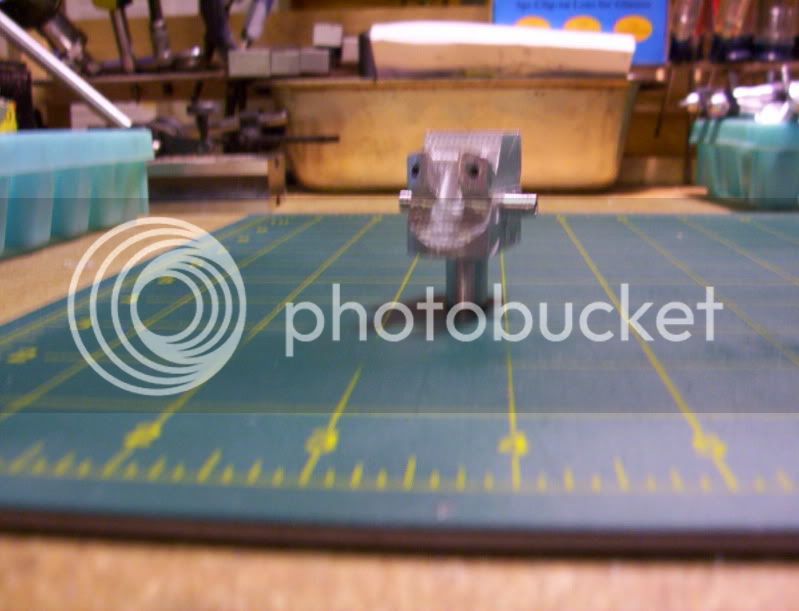

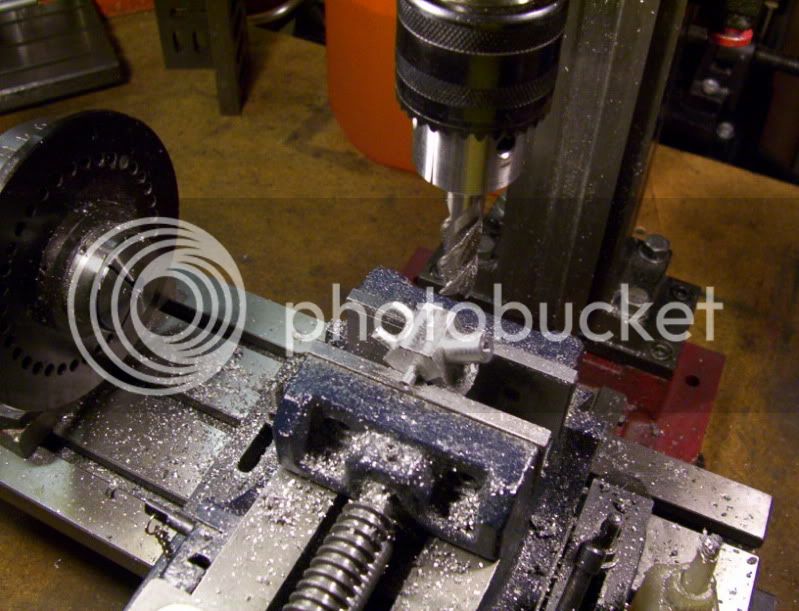

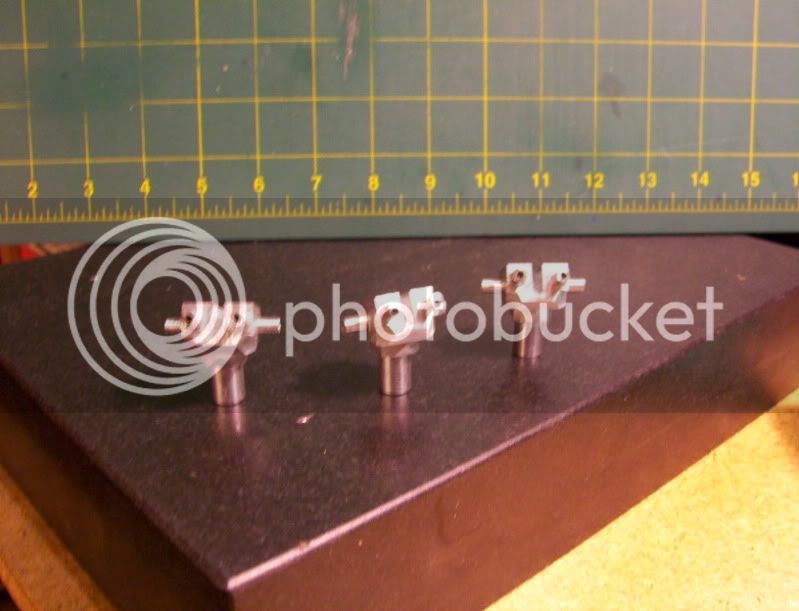

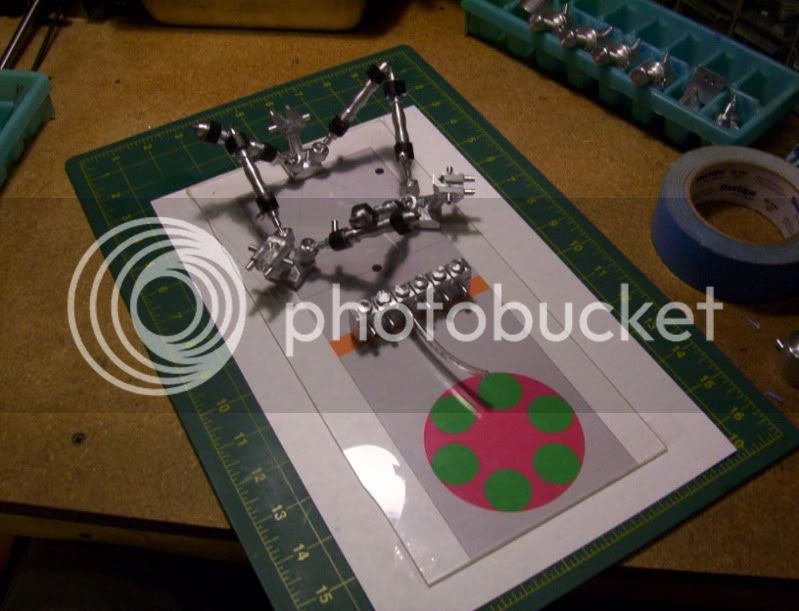

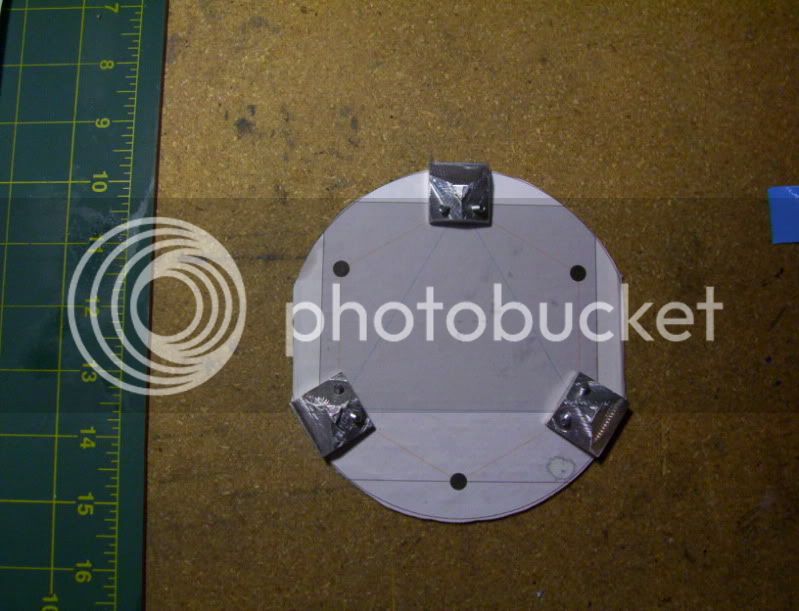

After forming the spigots on both sides, I'm now ready to continue on where I left off before the tool broke and ruined this workpiece.

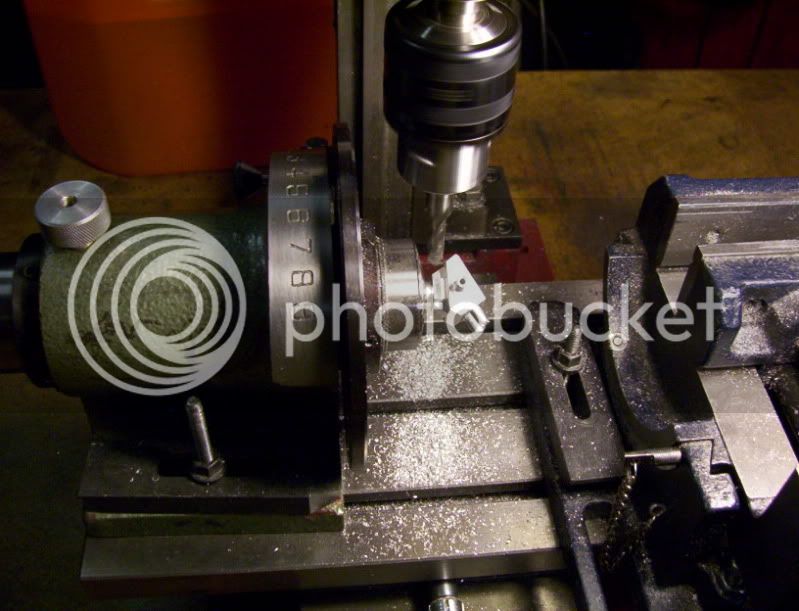

Now I can machine the front face 2 spigots.

The more machining I do on this piece, the more it smiles at me.

By making and fixing this mistake, has been again a Blessing in disguise, because I now see ways where I can use this method to make complicated parts where facets will be protruding and things, instead of machining it out of one solid piece, and making my little mill do alot of roughing bullwork,

I can dowle and glue pieces together that are close to finish size, then use my mill to machine to final profile dimensions, as if I were machining a casting, this way it would save a lot in material cost, plus I could use pieces of scrap to build up larger parts for final milling.

Another advantage would be, those difficult areas to machine could be almost eliminated, because I could machine certain areas before I fit and glue more pieces, in the area, I see great potential in using this method of building up pieces for a finished part, then machining to finish dimensions.

So anyway 2 of these parts finished one to go.

Have a great day...