Hi to all!

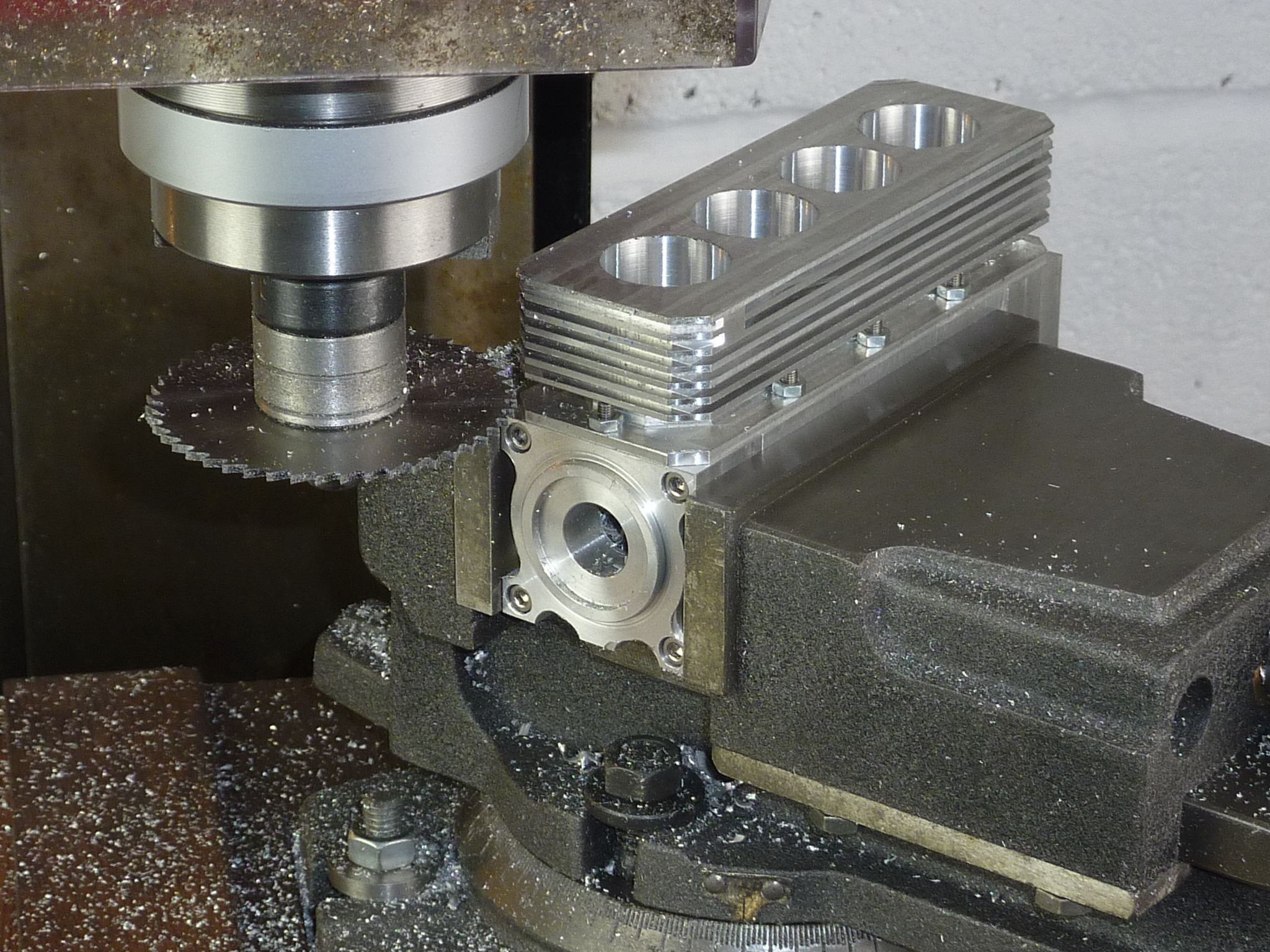

I'm hoping someone can impart some wisdom on a new guy. I'm trying to machine the cylinders for a radial I found on GrabCad. It's a relatively simple piece, but one part has me stumped. Is there a good/easy way to machine the grooves in the sides? I am working on a benchtop cnc machine with minimal tooling. I thought a woodruff cutter might work, but the piece is about 2.5" tall, and -- while the profile would be easy -- I don't think I can safely get enough reach. A person might be able to do it with the part turned on its side in a rotary table with the right radius, but I haven't had the money to purchase that yet. Any wisdom from the folks that have been doing this a while?

I'm hoping someone can impart some wisdom on a new guy. I'm trying to machine the cylinders for a radial I found on GrabCad. It's a relatively simple piece, but one part has me stumped. Is there a good/easy way to machine the grooves in the sides? I am working on a benchtop cnc machine with minimal tooling. I thought a woodruff cutter might work, but the piece is about 2.5" tall, and -- while the profile would be easy -- I don't think I can safely get enough reach. A person might be able to do it with the part turned on its side in a rotary table with the right radius, but I haven't had the money to purchase that yet. Any wisdom from the folks that have been doing this a while?