At one time I considered going into the casting kit business, but after talking to Maury with Lone Star, I could see that there would be no significant profit in it, and indeed most likely no profit at all.

One major problem I have hear from several folks who offer or offered casting kits was the fact that finding someone to do the foundry work was getting very difficult, the castings were very expensive to get made, and the casting quality was dropping to the point where many castings were poor quality, and had so many defects that they required a lot of work to use.

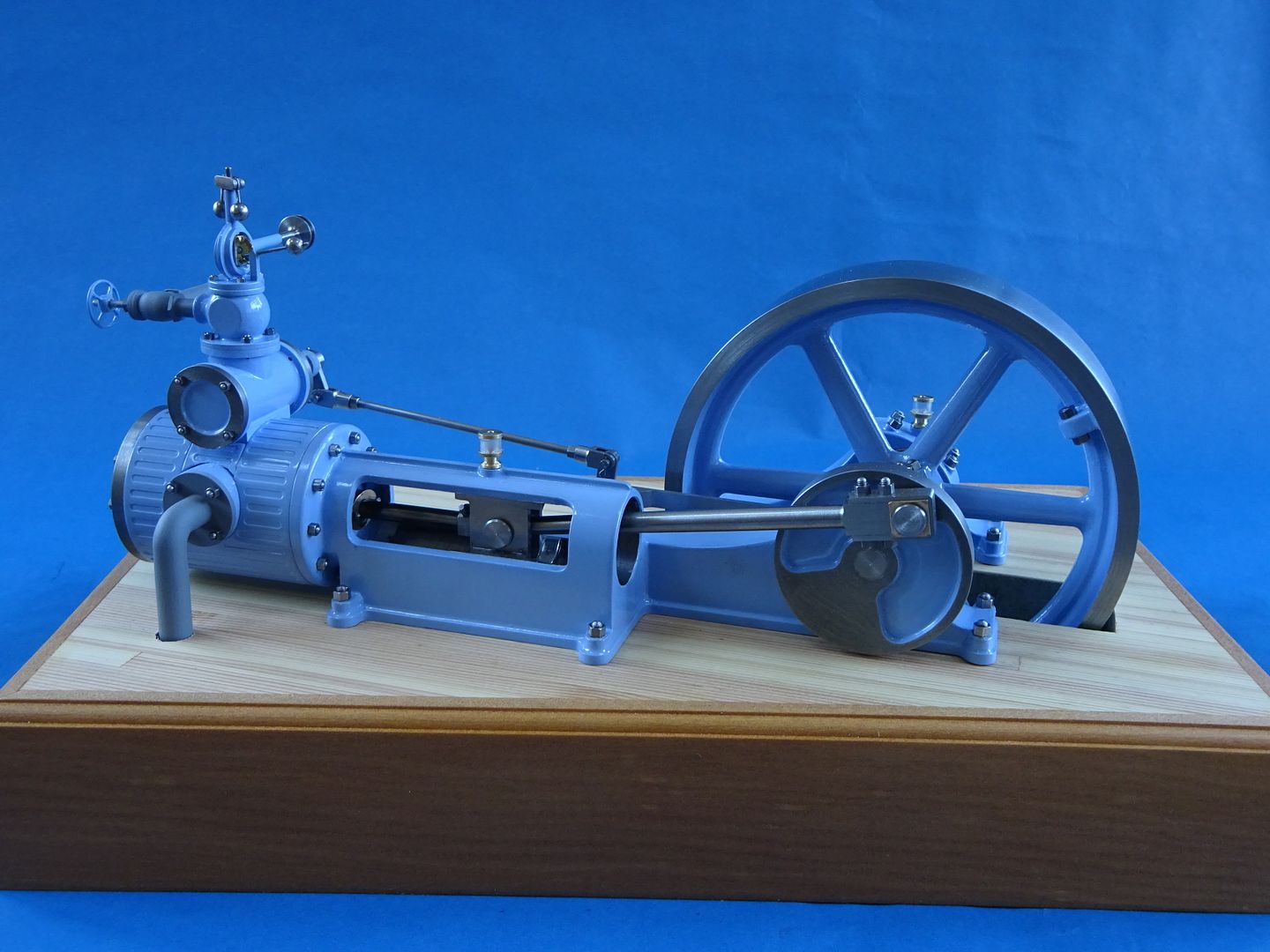

I ended up building my own aluminum/bronze/iron foundry, and I make my own patterns and cast my own engine parts.

It took me six years on and off to learn how to do foundry work, and how to make defect-free gray iron castings.

Most people don't even believe I can make defect-free gray iron castings that do not have inclusions or hard spots.

So far nobody has taken me up on my offer to come over to my house and witness this for themselves, and become a believer.

You can lead a horse to water.............

I have a 3D printer, and have shifted most of my pattern work into that format.

I start with a photo of an original engine, and then create a 3D model from that, and then 3D print the patterns.

With today's technology, one can make a better Coles than Coles, a better Cretors than Cretors, and even a better Stuart than Stuart, if you use the right materials and become proficient at 3D modeling.

Most of the casting kit folks in the past simplified or modified their kits, but there is not need to modify an old engine design; these days one can reproduce an old design exactly as it was originally built.

The folks who make their own castings and engines sort of get ignored in my opinion by the rest of the hobby, for the most extent, but we are out here, and can make some superb gray iron engine parts.

I have tried to share my knowledge with anyone/everyone who wants to learn, but few seem interested.

The only thing holding me back right now is the fact that I work full time, and am extremely busy with work projects, and so no time for engine work.

This is the state of the hobby in 2023; make your own castings; we have the technology.

.