The cord looks to be about 1/16" diameter and is white in color,

What is used is sometimes called butcher twine it is a small dia 3/21 strand twine made from cotton. 3 strands of 21 threads. it does comes from about 1/16" or in mm sizes even in the states. It is sold as a macrame string/thread. Most of the better stocked craft stores would have something like it. They are larger dia. so you can change the size to fit the pipes.

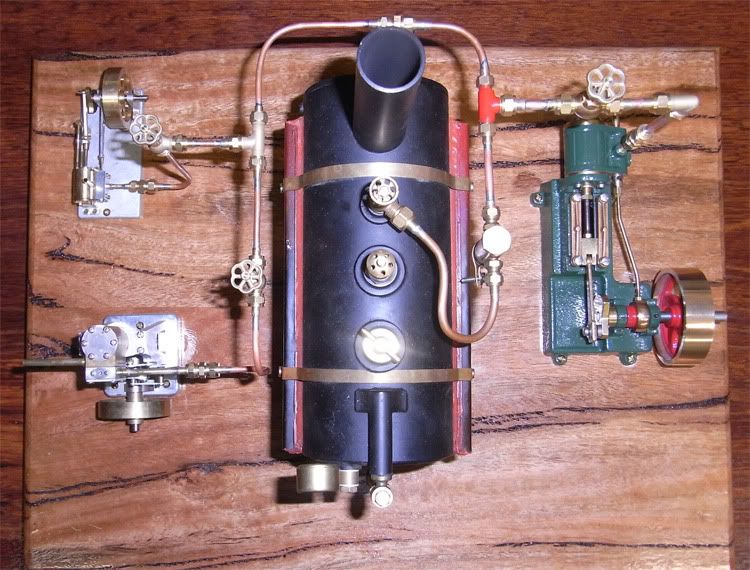

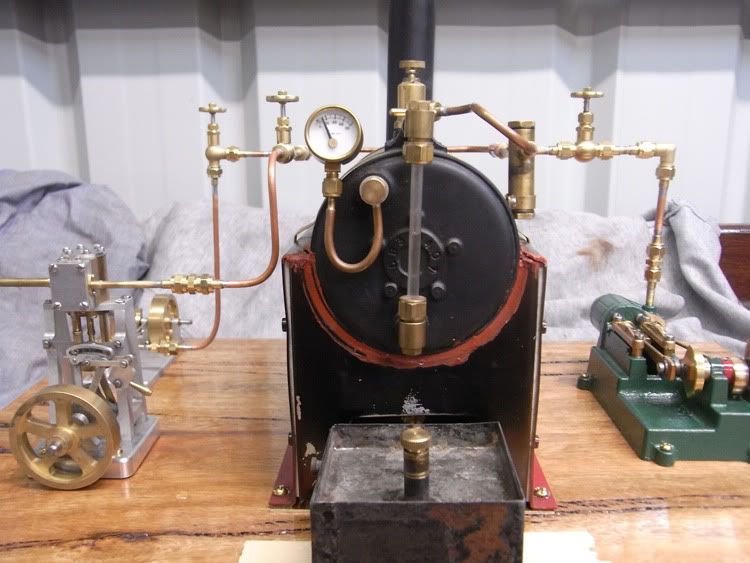

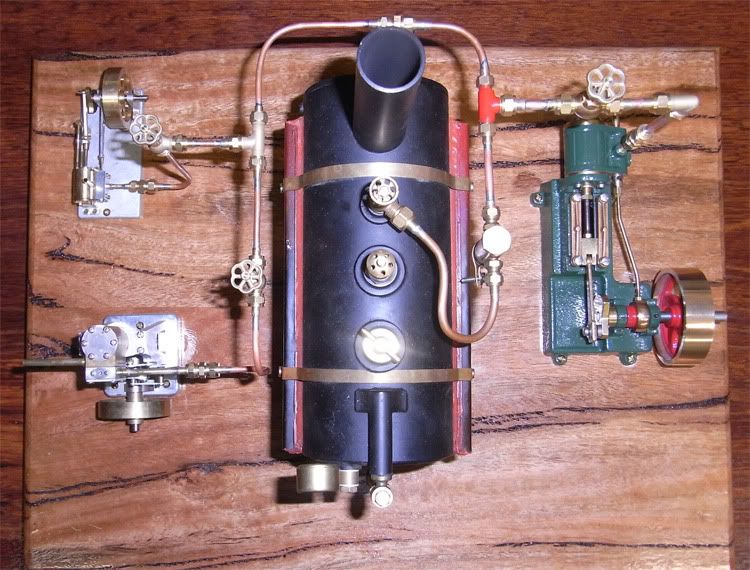

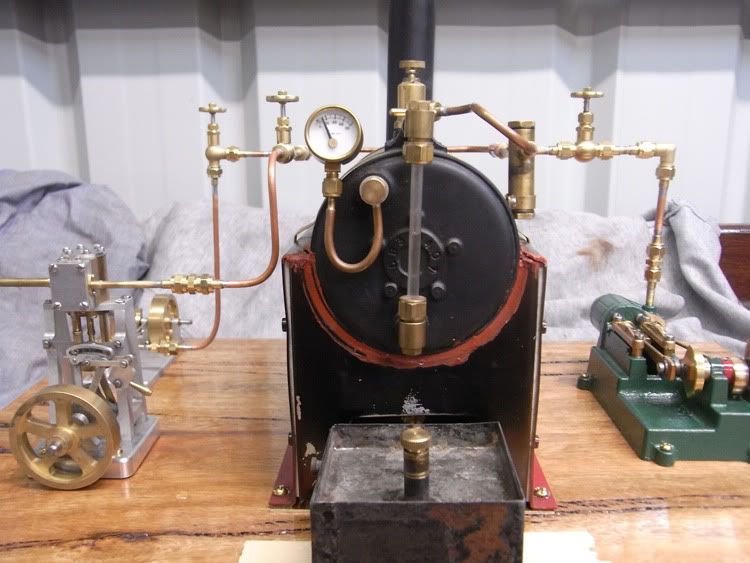

It is the same rope work that they do on ships railings, so and good fancy note book should have some ideas. They do some fancy monkey fists at the elbows and valve bodies.

The simplest form is ½ hitches around the pipe, with the hitch or knot part in a line along the bottom side of the pipe. When it is done they they paint them with a special sealer coating. to keep the dust out. As getting the dust and debris out of the rope is a pain. So painting is a must with the miniature lagging. More so with the rope/string style.

The other kind is a layer fiber glass insulation batting. In the states here a good source is frost king pipe wrap sold at all the big box home stores. the batting is about 2" wide and 20 feet long or so and 1/4" thick. You wrap the batting around the piping and secure with thread. Then you will need a thin light weight muslin or linen material . Seam tape or basting tape wide enough to wrap around the pipe and over lap the edges. it can be glued on or sewn as the old time pipecovers did. Again the seem on the bottom.

This is also sealed or painted to keep the dust and dirt out. The seams are all ways placed on the underside of the piping to keep the cleaning/repainting problem to a minimum.

The colors chosen generally reflect the in house color code or what the contractors has the most paint for

I have also seen somebody that used the fiberglass batting and then electrical heat shrink tubing. Two important things with this method, is he said it took sometime to get the hang of it,as you had to have a lot of extra tubing to cover joins etc. And it took some practice to get it right as he started in the center and worked out to the ends of the pipe runs.

And it works better with threaded pipe rather than soldered piping of any type. I'm sorry I didn't get any pictures of it as he was gone from the show when I got my camera and had gone back to take some.

Edited to add missing sections:

*Asbestos/magnesia mud was used at the elbows, and valve bodies. The pipe sections were covered in formed blocks of the same material. Wrapped in what was called wild weave muslin (or in the old days a canvas like fabric.) so it doesn't unravel when torn.It was then dipped in wall paper paste to hold it in position. Then it was sown together. Can't remember what the type of stitch it was called but they had a special one they used.

When fiberglass became popular they used sections and the mud. Then formed pressed fiberglass elbows and bodies for valves. This also was covered with the fabric which was dipped in wall paper paste to hold the fabric in place on the pipe runs and elbows and valves, and then sown.

When they perfected the aluminized backed heavy craft paper covering with a peel and stick tape strip. It speeded up the application. Before the formed plastic skins the plastic came on a roll about 3 foot wide and 150' long.

*

The above are the ways they do full size equipment other than the plastic skins over some magnesia formed insulation, and the stainless steel skin sections. They probably have come up with some new stuff in the last couple of years.

glen