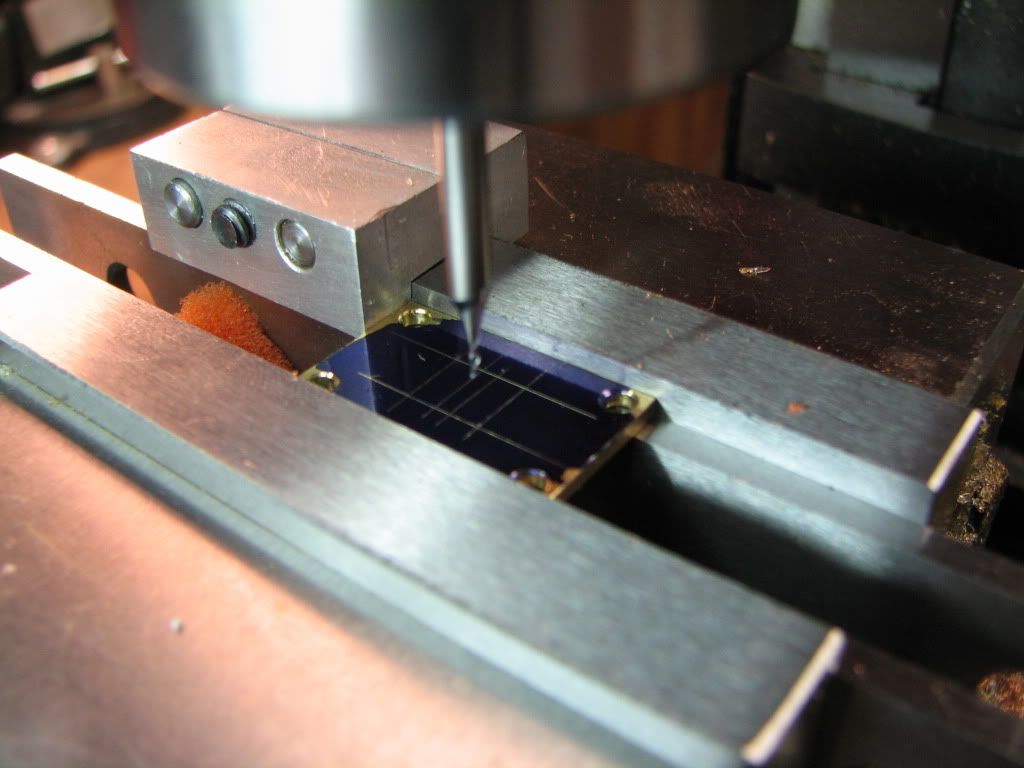

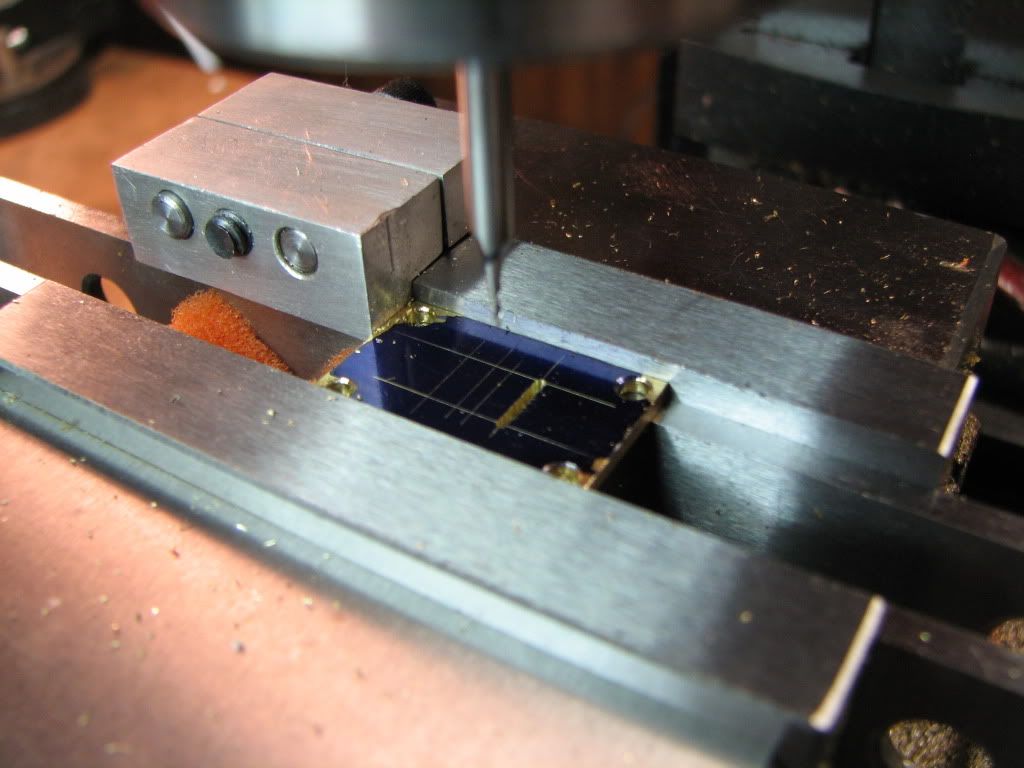

Well it's time to start fitting and sweating...

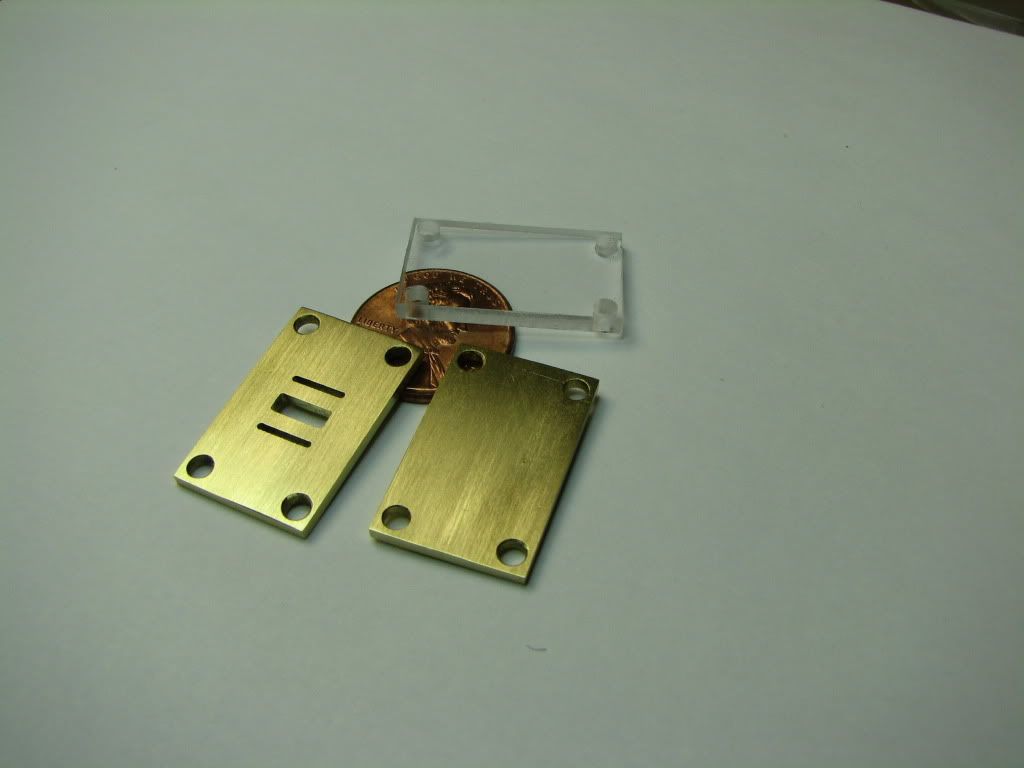

Here's a pic of all the parts I've made...okay okay...'good' parts...

I didn't show the screws and pins that came with the kit.

Here's a pic showing some of my travels...

Not all the parts are there...I managed to re-use some of them.

Two drill bits and a tap sacrificed themselves...okay okay...were killed by me.

There's at least 3 evil handles in there too.

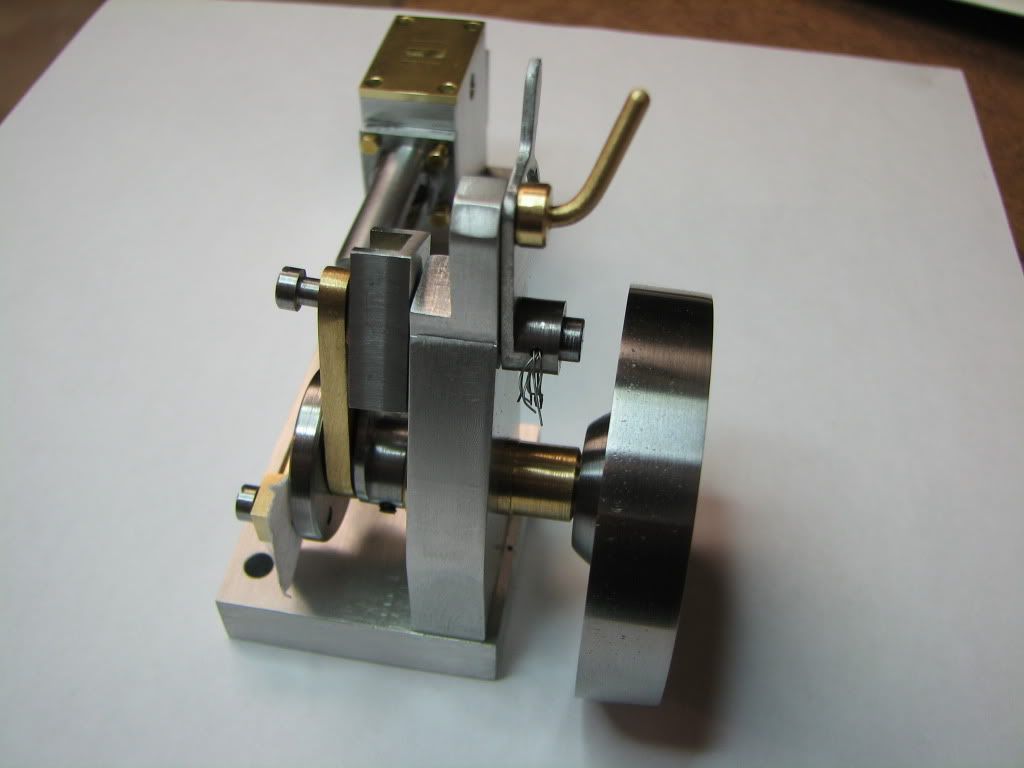

And before you all go posting on me...that's right...the flywheel is missing.

For whatever reason, I've been struggling with that. I had much less trouble on the flywheel for the launch engine. I don't know what's going on. Certainly some of it was not having the cutter in the right place. Some of it was not having it ground properly. (Insufficient clearance so there was some rubbing going on.) I've tried a carbide, a carbide insert, and several HSS (one of which I ground). The thing that really gets me is that the HSS tool looks like it's being ground by the flywheel. It's not rubbing as far as I can tell. But it's getting gouged.

In any case, my time is limited...I'm on vacation with many plans for the shop that I dearly want to get done. ;D

So I may just use the flywheel as is until I have time to make another.