Deanofid said:

Didja have to mention "Found a Peanut"? Just got that outta my head a few days ago...

Glad to help Dean. If it gets it out again, let me know. ;D

....................

Re-drilling went better than expected...

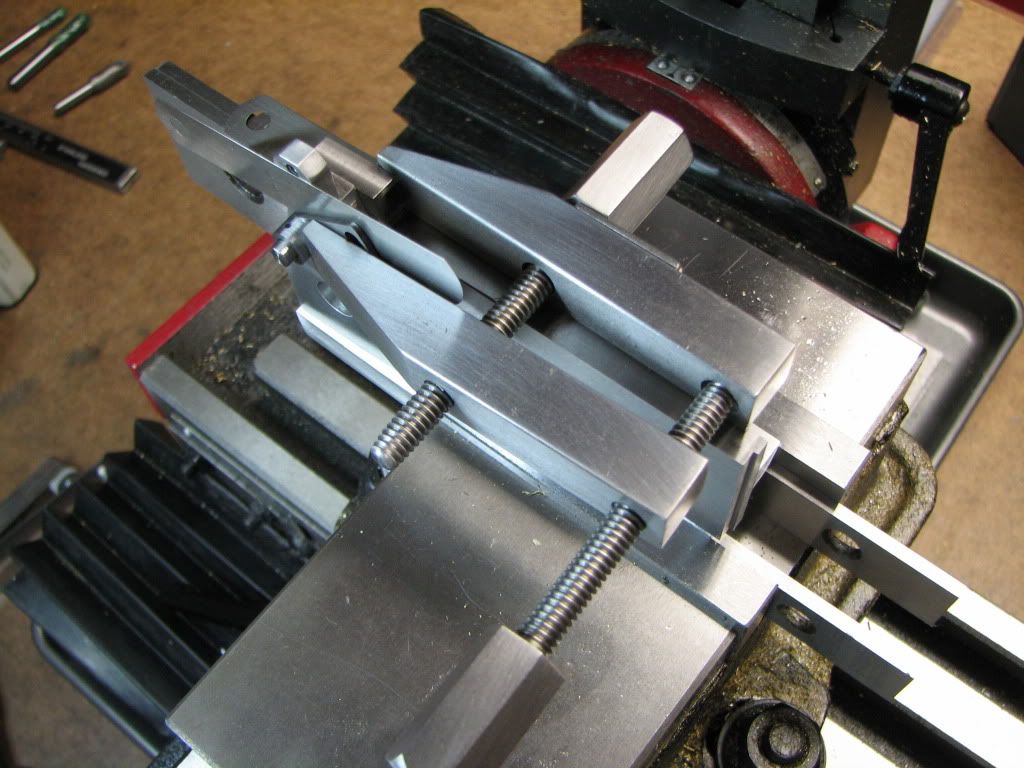

Here's a pic of the setup...

I actually used my machinist's clamp for the first time. Thanks to Arnold for getting me to think about it again. Parallels and shims under the tilting valve to keep it parallel. (That part was per instructions.)

The pin measured .061 to .062. Now I know why the instructions said to drill and ream even though the dimension was .05. Must be another dimension they changed to 'make it different'. I drilled with #53 for .0595. Tight fit. No loctite needed. Should be fun if I ever have to take it apart. I don't know why it couldn't have been a small set screw.

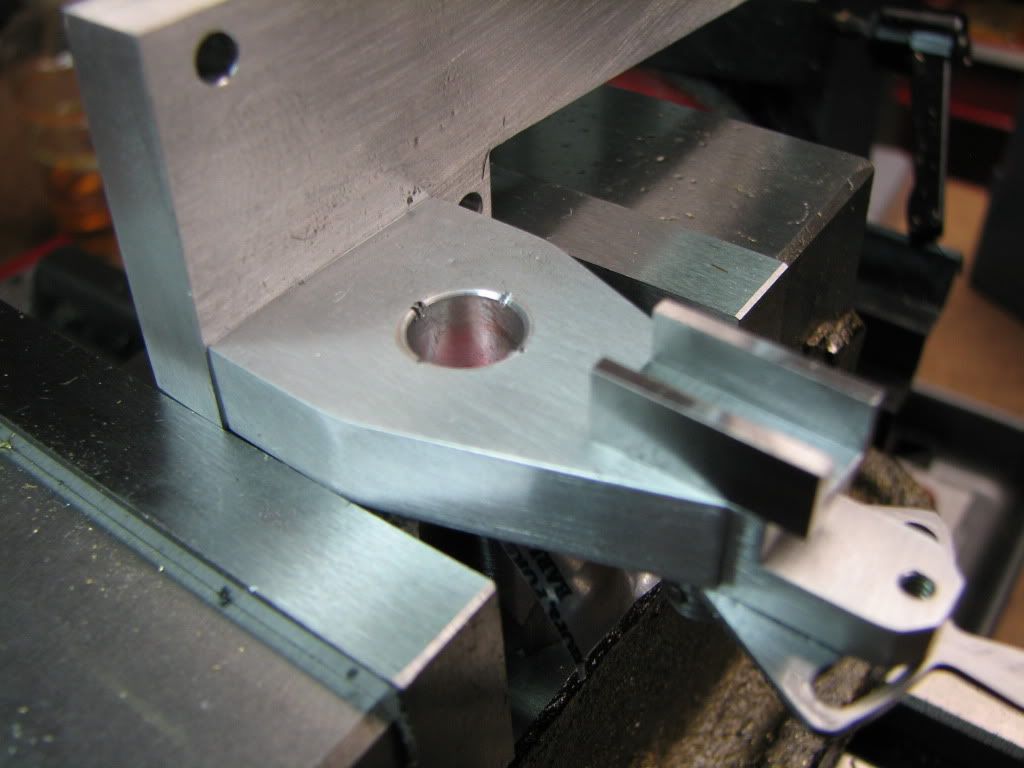

Then the bushing...

Also went better than expected. I expected disaster and nearly achieved it.

There's a machinist jack I made under there with a bit of soda can on top. I dinged the edge with a screwdriver. Probably should have done more. Fit was tight so I went for it. Then found out that once the bushing was in place...it wasn't tight anymore.

I went for the loctite anyway. Loctite everywhere. Between the column and the base, in the screws.....sheesh. But I managed to get it apart and clean it up before it set. (I was prepared with towels and cotton swabs). Then I noticed the oil hole in the bushing wasn't straight up. A little turning and I noticed it was getting tight. So maybe it'll work.

Still have a good flywheel to do...it's beginning to look like a do-over. But my bandsaw isn't set up yet.

......................

Dean..these might help too...

The Ants Came Marching

On Top of Spaghetti

If You're Happy and You Know It

I've Been Working on the Railroad

and the ever popular

A Hundred Bottles of Beer on the Wall