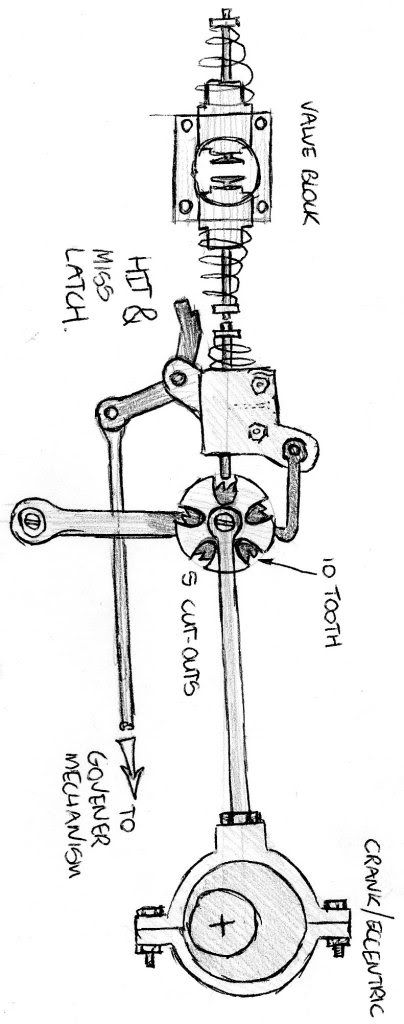

Hi, after joining this site it has given me some motivation to re-start my IC project! so i have dug out the parts previously made and am now going to carry on making the engine. The cylinder is finished and is of air cooled design, the crankshaft im using is from a stihl chainsaw (cheating i know, but it will do for a first engine) the engine frame is also made. The flywheels are fabricated items and are mostly complete, I am in two minds weather or not to make it hit and miss or throttle governed yet, hit and miss does appeal to me though. Here is a few pics of what i have done soo far, please feel free to comment. James