- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

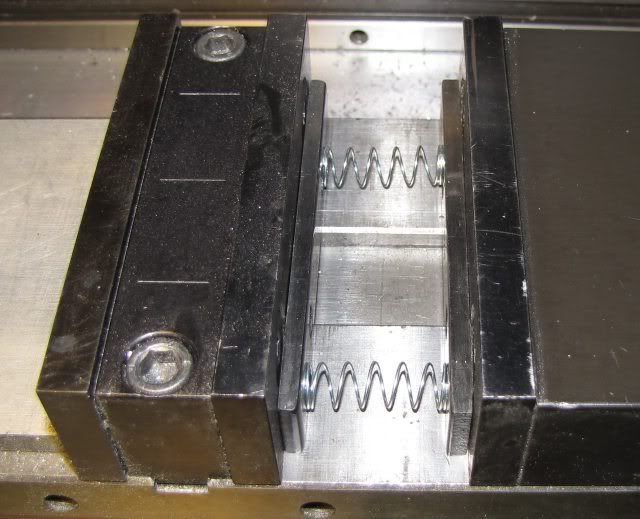

A few years ago I assumed that everyone who had ever used a vice on a milling machine knew about using springs to hold the parallels against the jaws as in the first photo. Then I was visited by a budding model engineer who had been a job shop machinist for about 15 years. While demonstrating something I put a pair of parallels in the vice and put a pair of springs between them and he thought that was the neatest idea. Even though he had been a machinist for a long time he had never seen it done.

There are lots of reasons to hold the parallels in place. A couple are that if you are doing several of the same part, it keeps the chips out from getting under the parallels when you change parts. It also keeps them from creeping under a tool while you are making an operation that requires going through the part.

OK, so most of you are like me and have a good assortment of springs in the tool box for just such purposes. I collect springs any time I can.

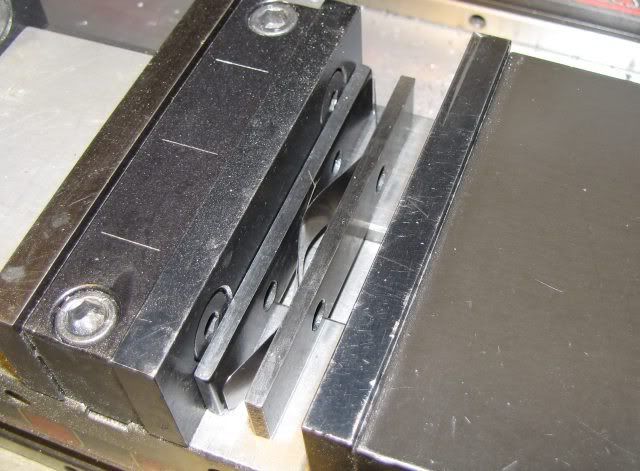

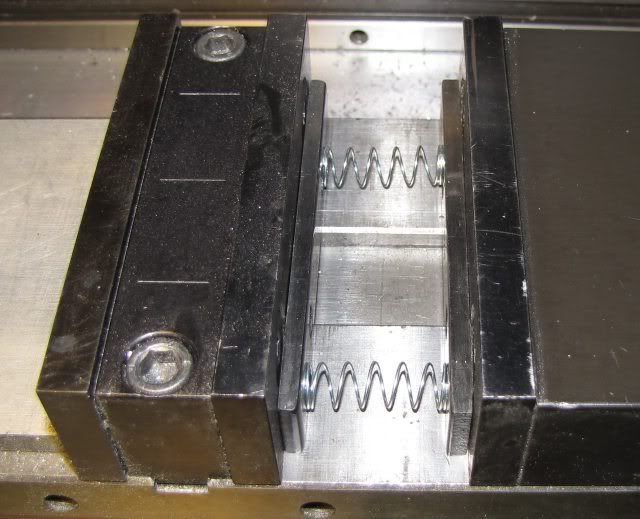

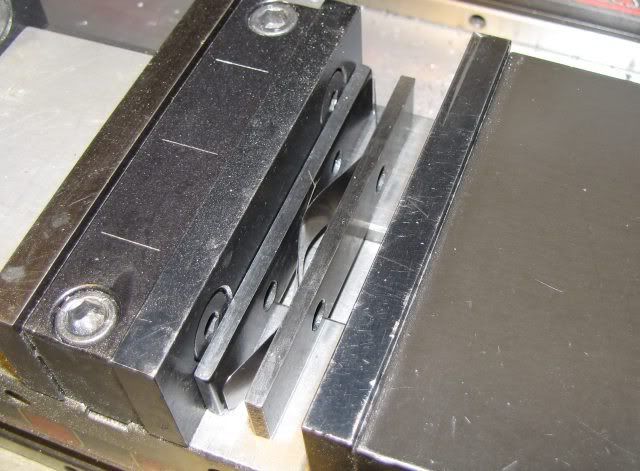

But what happens when the parallels need to be so close to each other that the conventional spring approach will not work. Enter the wave spring. I have several that I have made from feeler gage stock. They are about 0.010 inch thick. I just bend them with my fingers. You have to bend them quite a bit as the stock is quite springy. See photos 2 and 3. The stuff is springy enough that you can clamp it down flat and it will still spring by to the wave form. Now you can clamp down on parts as narrow as the two parallels plus the thickness of the spring plus a little bit for safety.

If that is still too wide, then take out one of the parallels and use a single one.

If you do not have any feeler stock, a strip of brass, aluminum, or steel shim stock can be pressed in to service. It will not have as much spring action, but it will work. I just make a single bend in it to form a shallow "U" or "V" shape in it.

Gail in NM,USA

There are lots of reasons to hold the parallels in place. A couple are that if you are doing several of the same part, it keeps the chips out from getting under the parallels when you change parts. It also keeps them from creeping under a tool while you are making an operation that requires going through the part.

OK, so most of you are like me and have a good assortment of springs in the tool box for just such purposes. I collect springs any time I can.

But what happens when the parallels need to be so close to each other that the conventional spring approach will not work. Enter the wave spring. I have several that I have made from feeler gage stock. They are about 0.010 inch thick. I just bend them with my fingers. You have to bend them quite a bit as the stock is quite springy. See photos 2 and 3. The stuff is springy enough that you can clamp it down flat and it will still spring by to the wave form. Now you can clamp down on parts as narrow as the two parallels plus the thickness of the spring plus a little bit for safety.

If that is still too wide, then take out one of the parallels and use a single one.

If you do not have any feeler stock, a strip of brass, aluminum, or steel shim stock can be pressed in to service. It will not have as much spring action, but it will work. I just make a single bend in it to form a shallow "U" or "V" shape in it.

Gail in NM,USA