MatiR

Well-Known Member

- Joined

- Jul 10, 2007

- Messages

- 65

- Reaction score

- 7

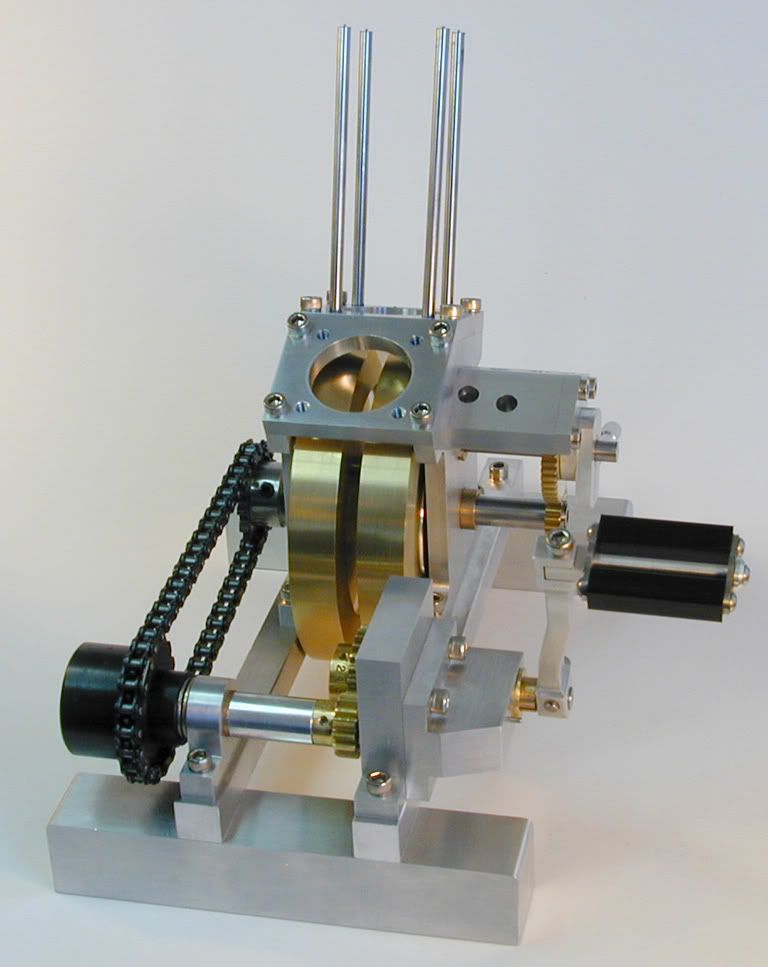

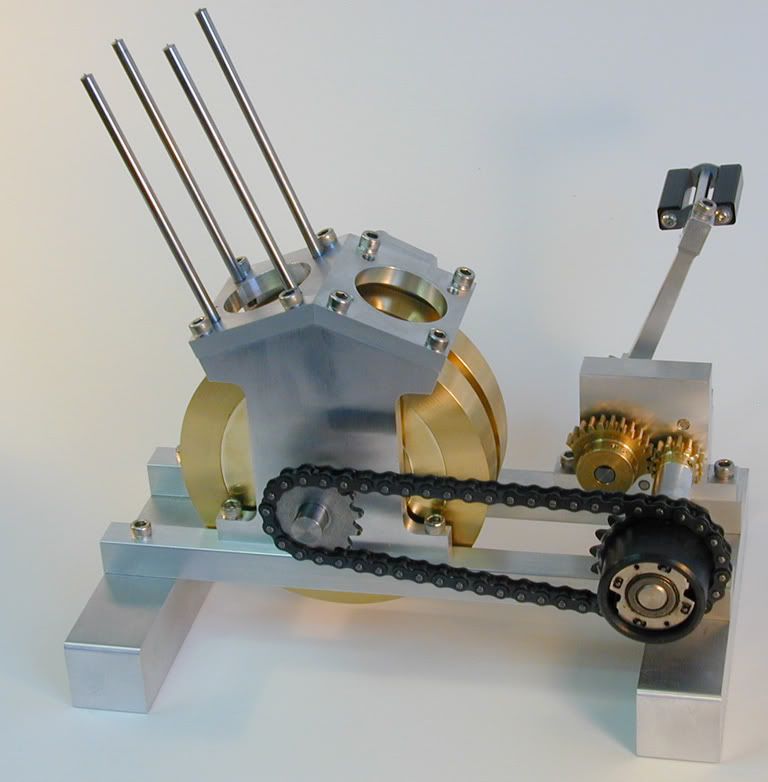

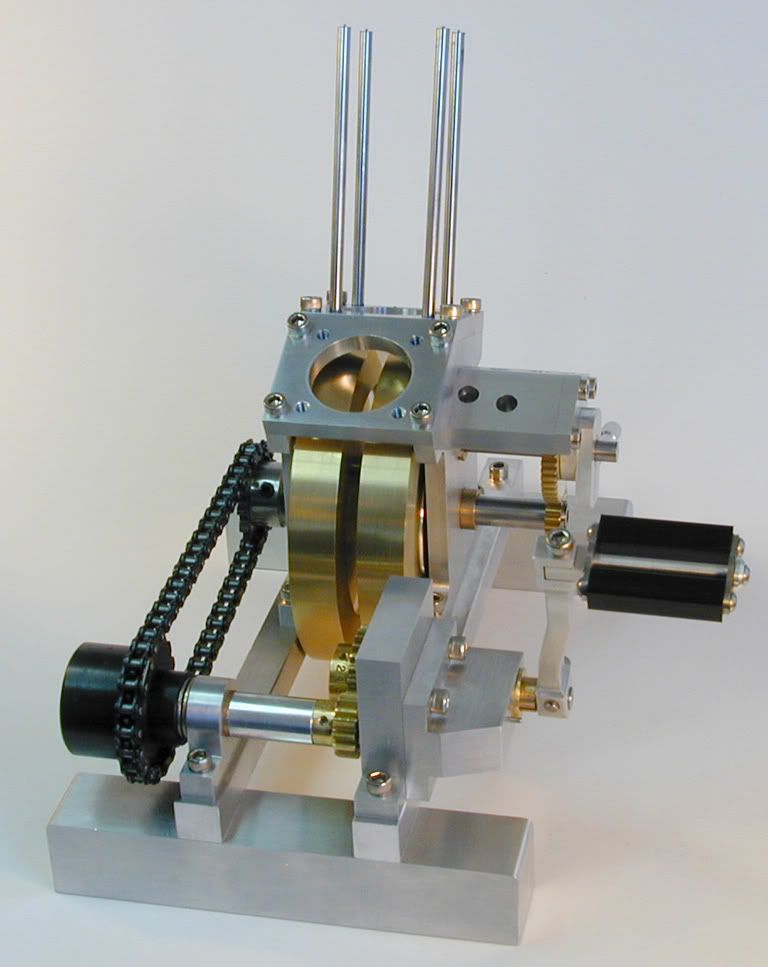

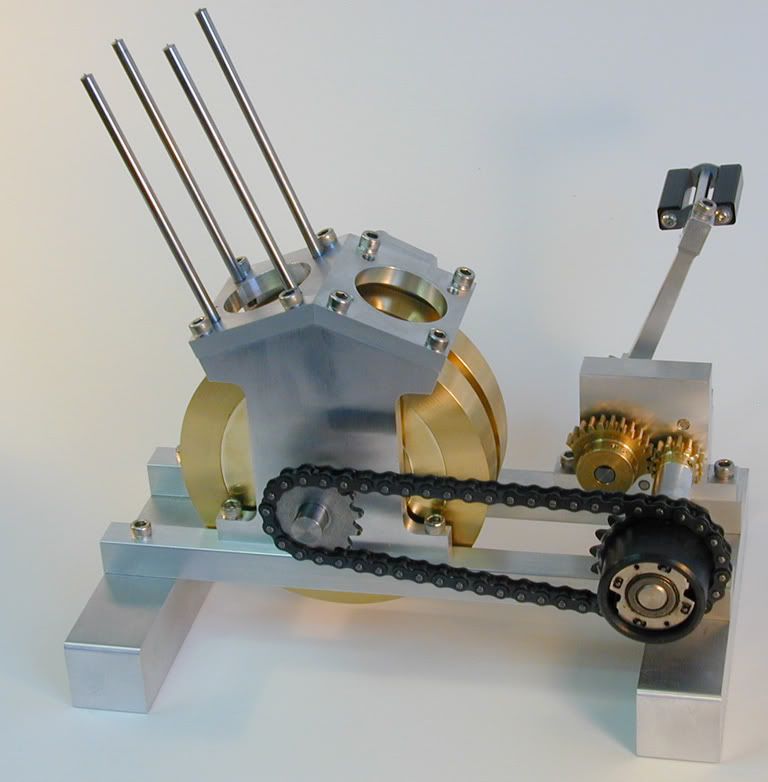

Had my camera at home after all; though that I had taken it to work. As promised in my recent Upshur Twin thread, here are some quick pics of the Hoglet in progress. Plans are from Model Engine Builder magazine after the design of Randall Cox. I changed the fly wheel design to single disks from the two part design in the plans. I like the original design better, but was beyond the capability of my lathe. Still lots of work to do, especially the rather large cylinders (one shown) which will have to be done on a larger lathe than my Sherline. I managed to machine the bottom of one cylinder, but only with difficulty. The cooling fins and grooves are not possible. The cylinder heads also need intake, exhaust and spark plug ports. The Robertson screws on the front of the cam housing are placeholders until I can get some decent socket caps in that length.

Regards, Mati

Regards, Mati