MatiR

Well-Known Member

- Joined

- Jul 10, 2007

- Messages

- 65

- Reaction score

- 7

Hi Kustomkb:

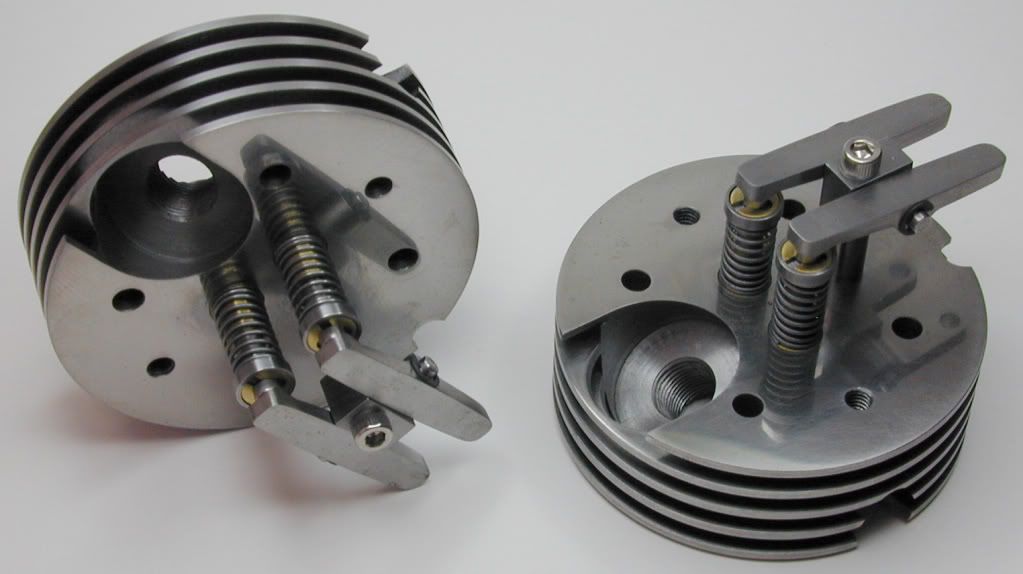

Since I last posted (I mostly lurk and enjoy), I have finished the cylinder heads, valve train, push rods, exhaust pipes, etc., and machined the bottoms of the cylinders. However, the cylinder bores and fins cannot be done on my Sherline (nowhere near rigid enough) so I am waiting to use an old 9 inch Southbend at work which won't be set up until January.

I got sidetracked with a Mills 1.3 project from Issue 1 of MEB which I just finished (was inspired by seeing Metal Mickey's posts here a few months ago). I am taking photographs of it this weekend maybe and will also post progress pics on the Hoglet.

M.

Since I last posted (I mostly lurk and enjoy), I have finished the cylinder heads, valve train, push rods, exhaust pipes, etc., and machined the bottoms of the cylinders. However, the cylinder bores and fins cannot be done on my Sherline (nowhere near rigid enough) so I am waiting to use an old 9 inch Southbend at work which won't be set up until January.

I got sidetracked with a Mills 1.3 project from Issue 1 of MEB which I just finished (was inspired by seeing Metal Mickey's posts here a few months ago). I am taking photographs of it this weekend maybe and will also post progress pics on the Hoglet.

M.