Dr Jo

Well-Known Member

- Joined

- Nov 1, 2011

- Messages

- 166

- Reaction score

- 13

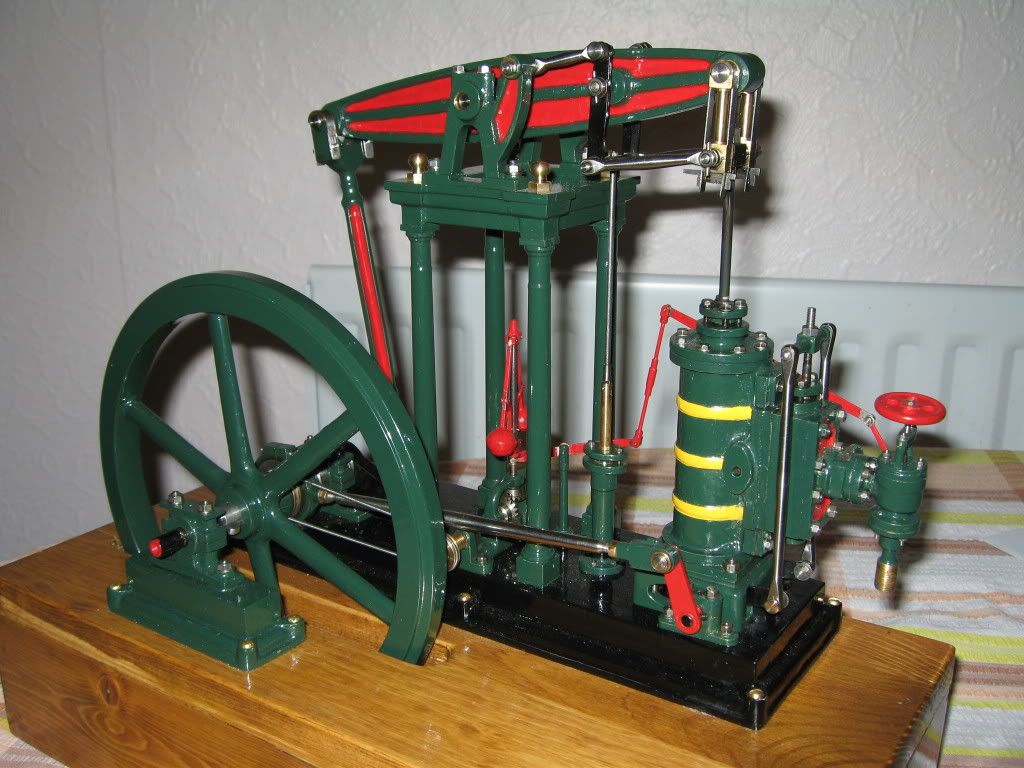

One of the things that I always seem to put off making is those fiddly small strangely shaped links which seem to be forever associated with governors!

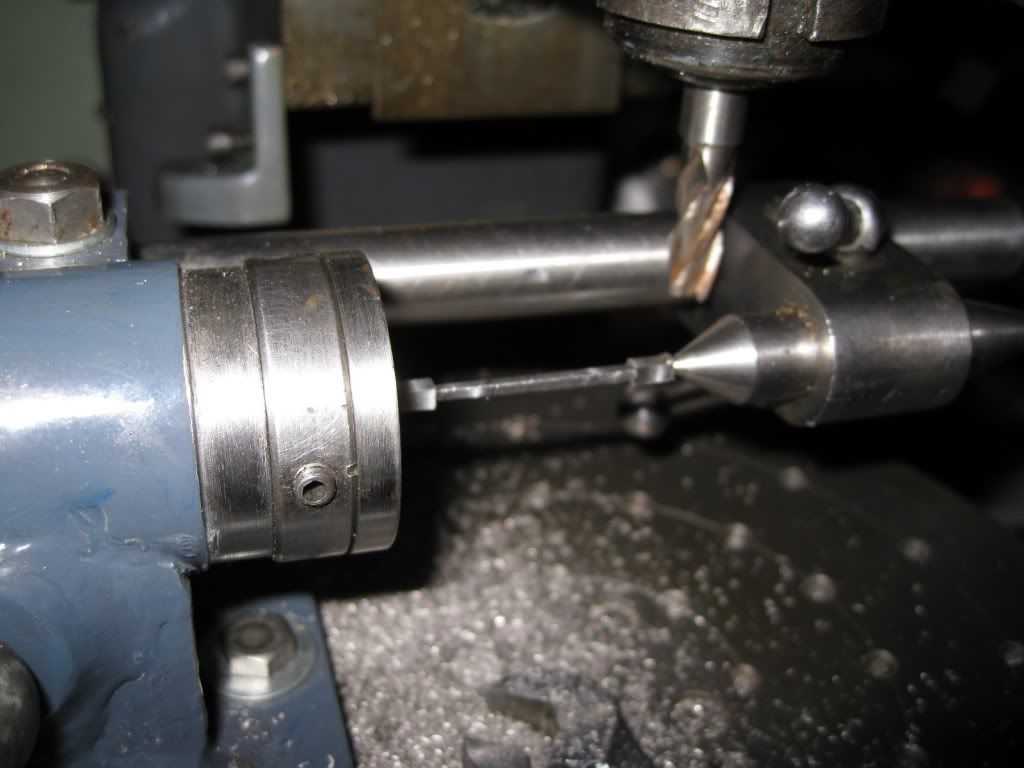

On Mary is there is a short 1.6mm square rod which has 2.8mm heads on either end. On Lady S I had made this using separate pieces but this time as the 2.8 sq is not available I decided to try mill them out of a piece of rod and cut the squares using the dividing head:

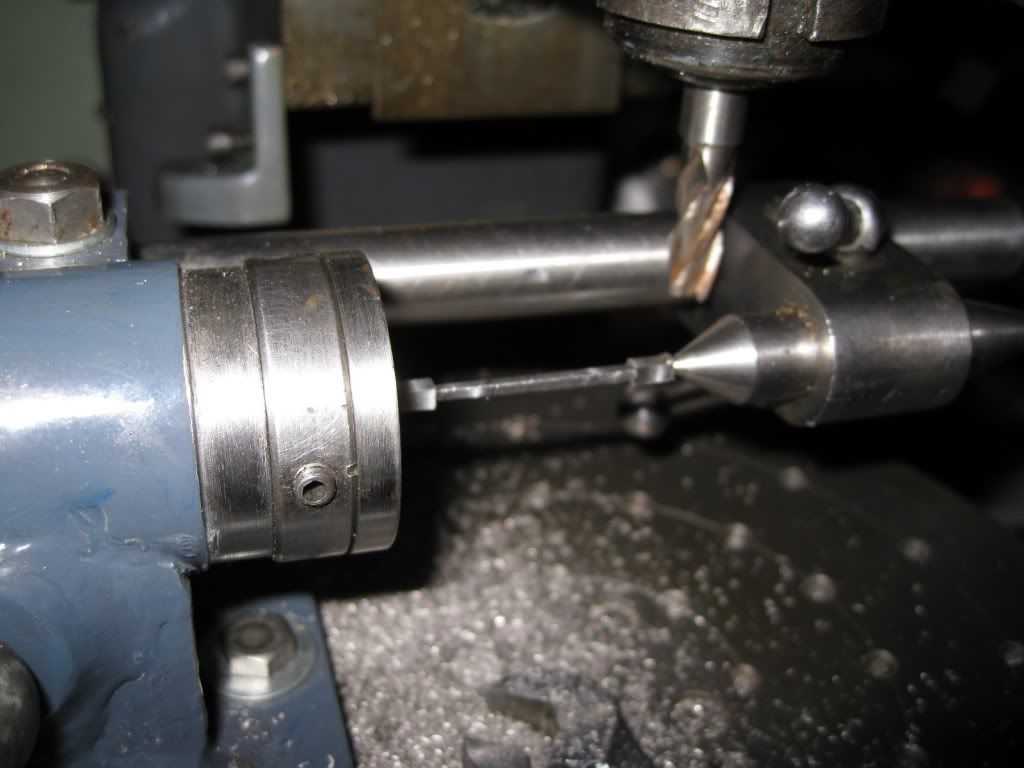

Over the years I have given up trying to mill the curved ends on rods this sort of size and am a great believer in filing buttons turned to size and fixed in place using super glue during the filing exercise.

On final assembly the rods are connected together using the male and female pins you can see to the left, after the 10BA nut, above the ruler. These have 2.4mm heads, 0.8mm thick, the working part for a female pin is 1.6mm thick which has been drilled with a 1mm hole for the male pin, the male pin has a 1mm diameter. The length of the female pin is adjusted for the application, the males are normally left at 3.2mm (or shorter if needed).

Jo

On Mary is there is a short 1.6mm square rod which has 2.8mm heads on either end. On Lady S I had made this using separate pieces but this time as the 2.8 sq is not available I decided to try mill them out of a piece of rod and cut the squares using the dividing head:

Over the years I have given up trying to mill the curved ends on rods this sort of size and am a great believer in filing buttons turned to size and fixed in place using super glue during the filing exercise.

On final assembly the rods are connected together using the male and female pins you can see to the left, after the 10BA nut, above the ruler. These have 2.4mm heads, 0.8mm thick, the working part for a female pin is 1.6mm thick which has been drilled with a 1mm hole for the male pin, the male pin has a 1mm diameter. The length of the female pin is adjusted for the application, the males are normally left at 3.2mm (or shorter if needed).

Jo