I am far from an expert on flycutters - in fact I am more or less a complete beginner so take what I say with a pinch of salt

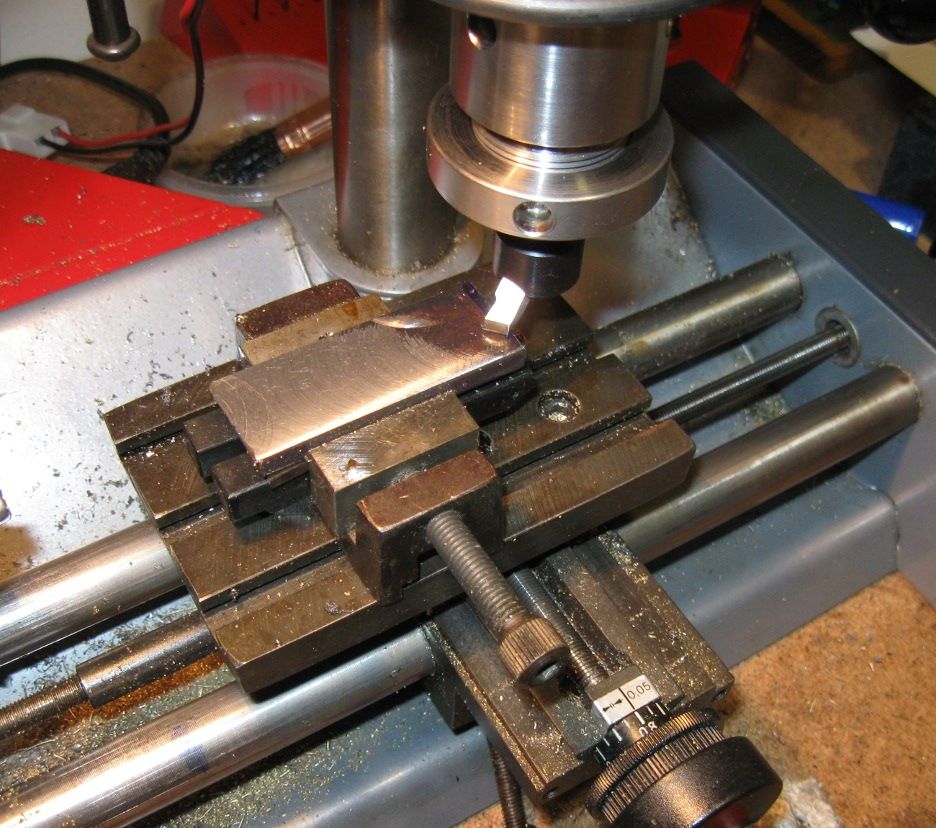

My first project was an Elmer's wobbler. While making this, one of the biggest difficulties I had was cross drilling as a result I decided to make a "finger plate" for my next project. I had a suitable piece of hot rolled steel for the clamp, it just needed to be cleaned up and made parallel all round. Being a bit too large to hold in the lathe chuck, I thought that it would be the ideal opportunity to try out the fly cutter that was amongst the accessories that came with my little Unimat lathe/mill.

My first attempt was a complete mess, I made sure that the bit was nice and sharp, I tried various speeds and depths of cuts but the surface looked and felt like steel wool.

Looking for a solution I came across a post by Bogstandard on one of the forums where he he used to post (it may have been here), where he gave details of fly cutter tool bit with a curved tip. After a few minutes at the bench grinder, I managed to produce a shape that looked something like what Bogstandard recommended, I couldn't believe the difference.

Hopefully these two pictures will help with the shape. The actual surface finish actually turned out far better than it looks in the second picture.

Unfortunately Bogstandard no longer posts here, and he has removed many of the images from his old postings. You could try contacting him (he hangs out on the Model Engine Maker Forum) to see if he would be willing to upload the images again.

Edit:

Oh I see that both basement_guy and Omnimill have beat me to it, that's what happens when one takes a coffee break mid posting