Wagner1975

Member

- Joined

- Nov 11, 2009

- Messages

- 13

- Reaction score

- 0

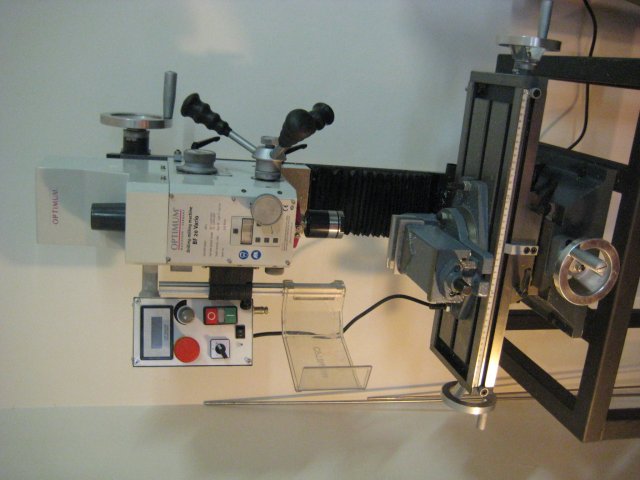

I guess one can never have enough tools, and since the misses are not gonna let me buy more  I decided to try my hand at making a flycutter, and then use that to make a rear toolpost for a parting tool. Didn't take many pictures, but here are some ...

I decided to try my hand at making a flycutter, and then use that to make a rear toolpost for a parting tool. Didn't take many pictures, but here are some ...

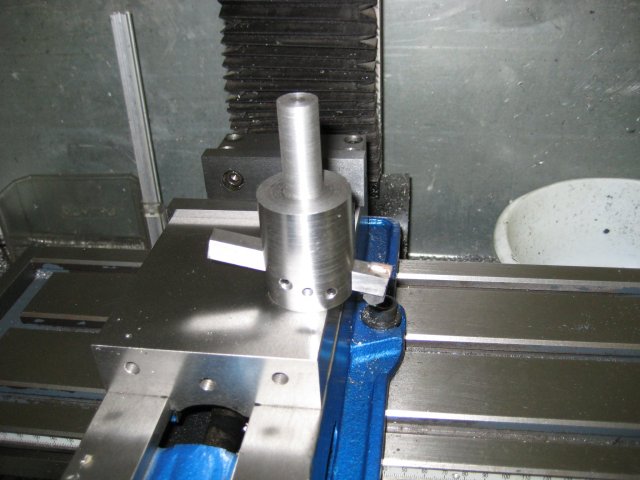

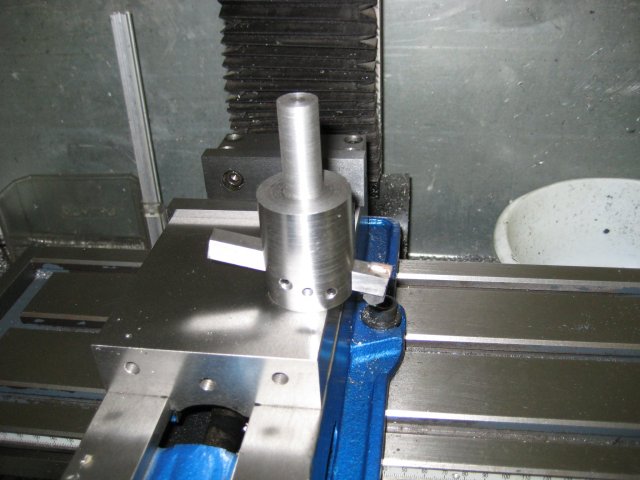

Turned the flycutter from one piece of 40mm silver steel, to fit my 16mm ER25 collet. Then cut a 10mm slot in the bottom to fit a 10mm tool, and then tapped 3 M5 holes for grub screws. I silversoldered a piece of tungsten into a slot I cut into a 10mm piece of keysteel to use as the cutter. Not perfect :big: but it work, as you can see in the next pics ...

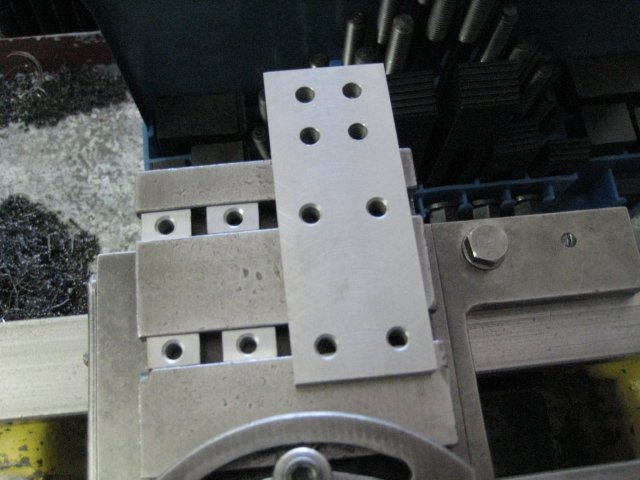

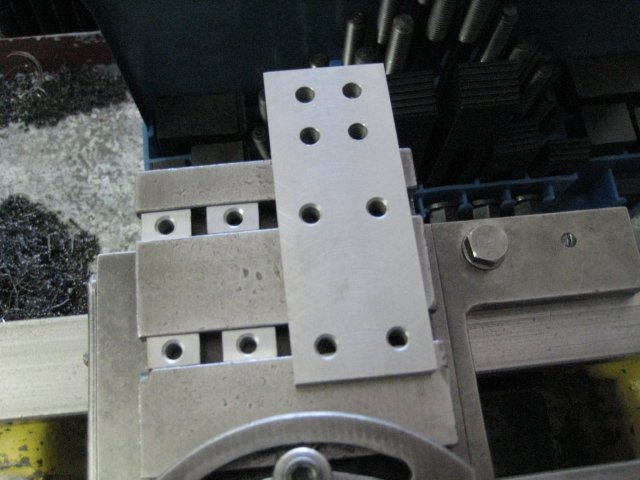

This is the base for the rear toolpost and the T-nuts I made for the Myford.

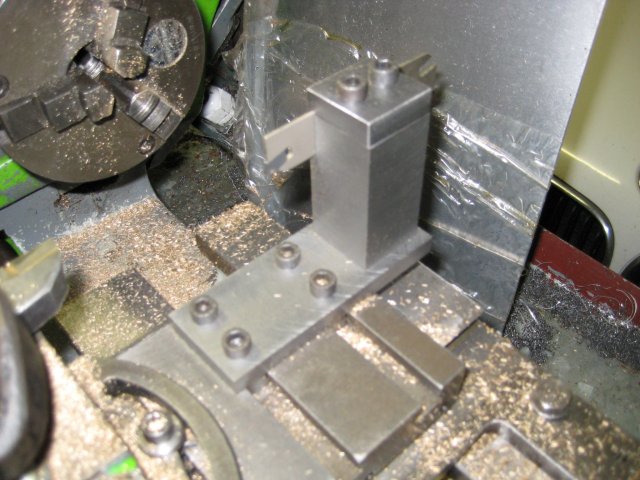

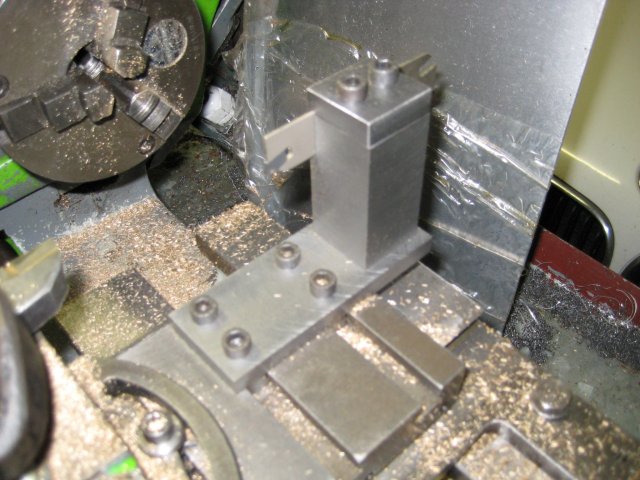

... and here is the parting tool that I wanna use, and the block that I'm gonna use to mount it in.

I cut with a dovetail cutter until the parting blade was at the correct height, and then made a top to clamp it tight!

And that's it finished and ready to make some chips! ;D

Dialed it in with a DTI and it cut through brass like butter

Turned the flycutter from one piece of 40mm silver steel, to fit my 16mm ER25 collet. Then cut a 10mm slot in the bottom to fit a 10mm tool, and then tapped 3 M5 holes for grub screws. I silversoldered a piece of tungsten into a slot I cut into a 10mm piece of keysteel to use as the cutter. Not perfect :big: but it work, as you can see in the next pics ...

This is the base for the rear toolpost and the T-nuts I made for the Myford.

... and here is the parting tool that I wanna use, and the block that I'm gonna use to mount it in.

I cut with a dovetail cutter until the parting blade was at the correct height, and then made a top to clamp it tight!

And that's it finished and ready to make some chips! ;D

Dialed it in with a DTI and it cut through brass like butter