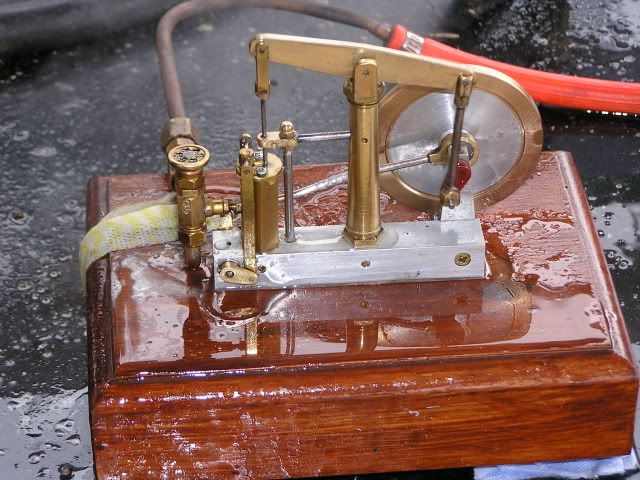

Well, after almost a year my emler beam is "finished". I finally got around to stripping it down for a clean/polish, mounting it on a board, and making a small control valve to regulate the speed, with about a week to spare before taking it to the annual "Echuca steam and Horse Rally" in Northern Victoria, Australia.

For those that have questioned in the past whether Elmer's beam engine would run on steam, I can now say Yes it can, but best if you don't. Firstly, unlike compressed air that you can only faintly hear, leaking steam/water is much more obvious when showing up your leaking glands/joints.

Secondly, the heat of the steam does a great job of stripping the lacqer and tarnishing all that brass that you spend hours polishing. However, that said, the engine ran consistantly all day and was a real crowd pleaser, especially with the younger audience.

A couple of photos prior to being packed in the car for the trip

"In action" at the rally - sorry no audio on the video (must get a new camera soon)