I am making the valves for a Farmboy engine. I would like to know if I should machine the valve major diameter .375 out on the end of the shaft and have the small .125 dia. near the chuck to part it off when finished. I'm leaning to having the .125 turned on the end of the shaft towards the tailstock in case I need to use a live center in it. I have it machined to a dia. of .375 for the 1.560 length. I can choose either way to do it. Thanks , Boot

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Farmboy valves

- Thread starter Boot

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Cogsy

Well-Known Member

The way I normally make them is turn the whole piece to the major diameter, with enough material sticking out from the chuck to make the whole valve without moving it. Then I turn a small section, say 1/4" at a time (starting at the tailstock end), down to the stem diameter. That should minimise deflection of the stem as you cut it. Once I've repeated that enough times for the length of the stem, I cut the head angle and it's done.

If you leave a good bit of material extra on the head of the valve, it makes a great handle when you're lapping the valves. Once the lapping is done you just poke it back in the lathe and part it to correct length.

If you leave a good bit of material extra on the head of the valve, it makes a great handle when you're lapping the valves. Once the lapping is done you just poke it back in the lathe and part it to correct length.

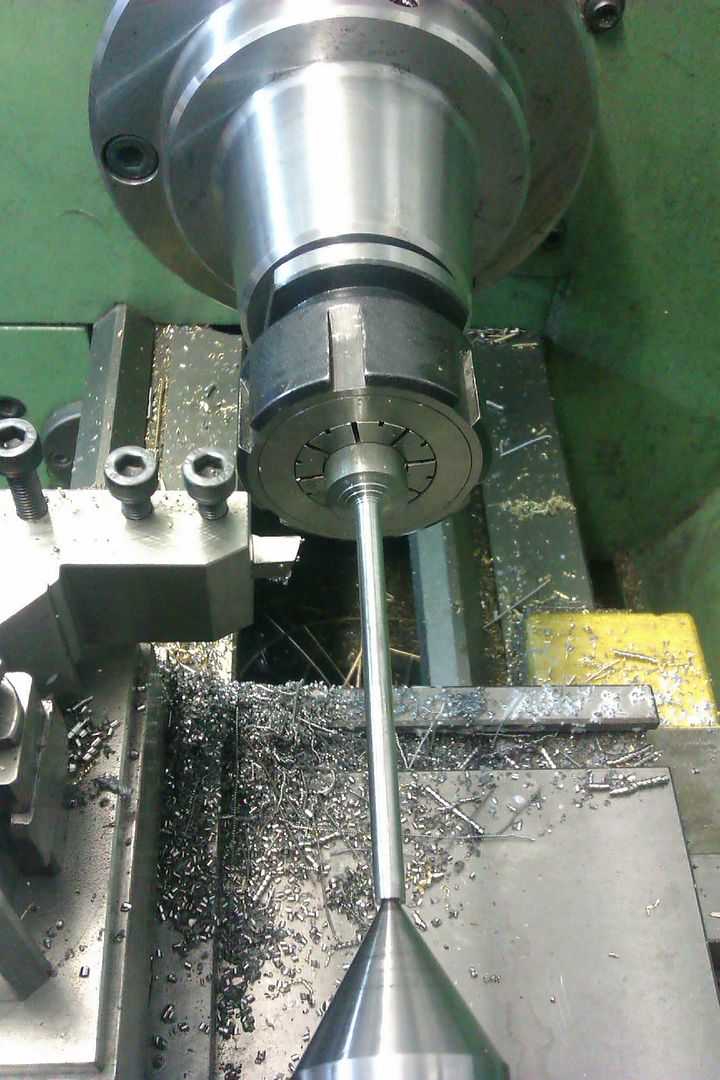

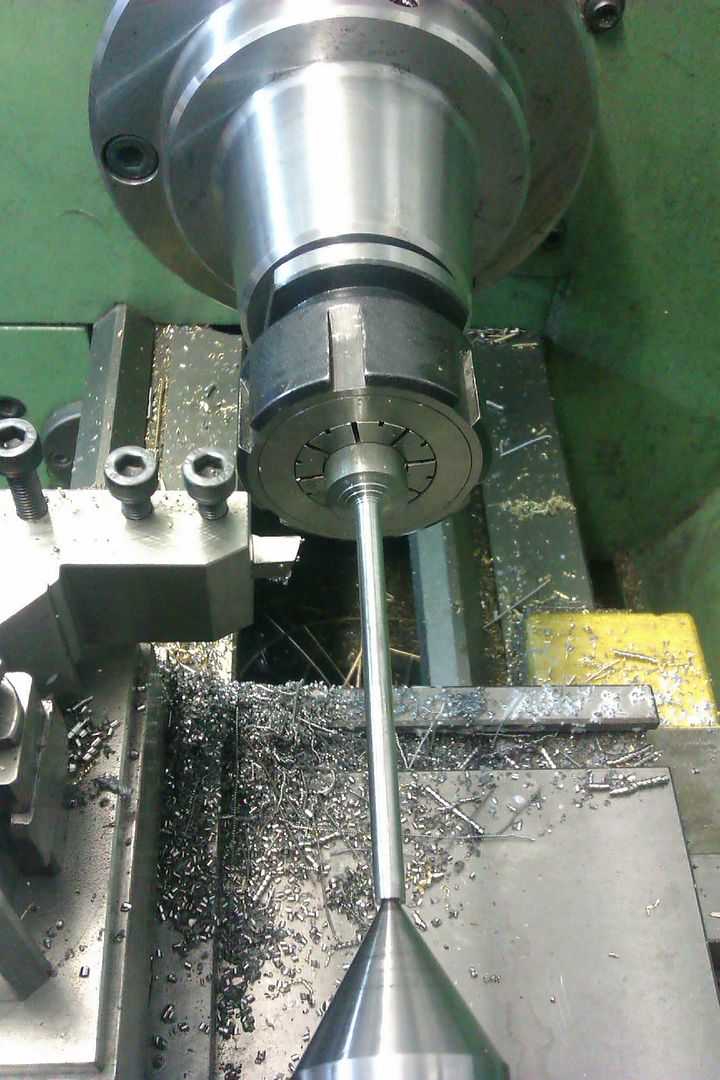

I face and centre drill the end and then slide out about 1/4" more material than needed. This allows the stem to be turned down with less risk of deflection due to the tailstock support, once all turning is done I part it off.

The excess on the stem can be turned away to get rid of the hole by holding in a split bush that is larger than the head dia or somethimes you can get them in a collet if the gripping area is not too long.

Another advantage is that before parting off yopu can use the rest of the bar as a handle while you grind the valves into the seats.

J

The excess on the stem can be turned away to get rid of the hole by holding in a split bush that is larger than the head dia or somethimes you can get them in a collet if the gripping area is not too long.

Another advantage is that before parting off yopu can use the rest of the bar as a handle while you grind the valves into the seats.

J

Cogsy is right. I use the same method on all my engines. I don't use a tailstock center like Jason, but only because the saddle is so wide on my machine that the tailstock center can't reach something as short as a valve and still leave room to move the saddle back and forth for machining..

Similar threads

- Replies

- 2

- Views

- 936

- Replies

- 1

- Views

- 891