I didn't find yet the spirit to restart the interrupted build of my engine (hope to do it tomorrow)

meanwhile, I spent the last weeks upon little works in the shop

I had bought times ago a great backplate (200 mm) for a 160 mm lathe chuck, but I have never used it, because I mounted the chuck on another backplate

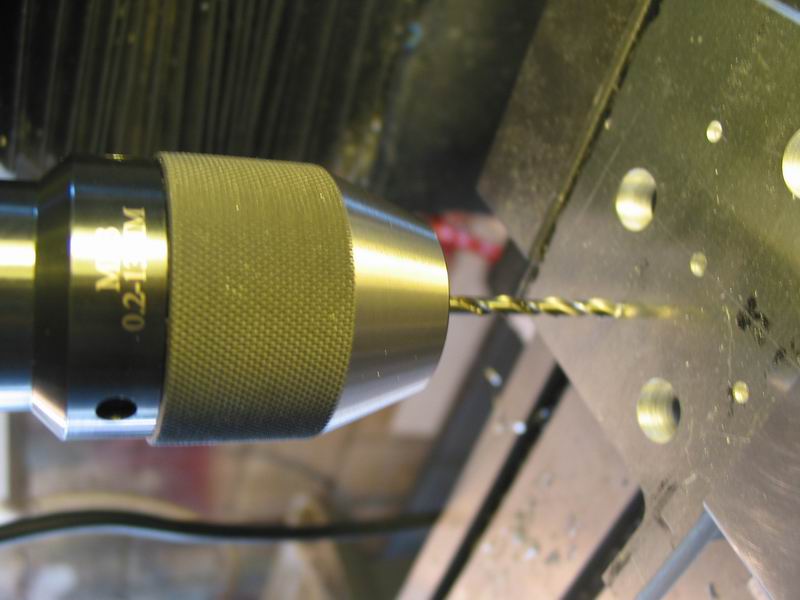

so in these days I have made a face plate with it. it is of cast iron, I brought down the diameter to about 180 mm, made the thread for the Boley spindle nose (40 x 3,5 mm) and worked the face of the plate

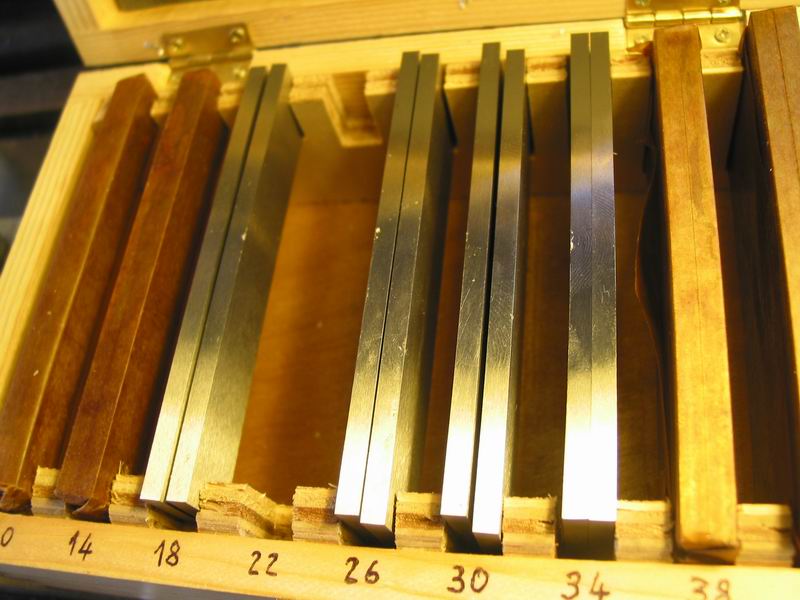

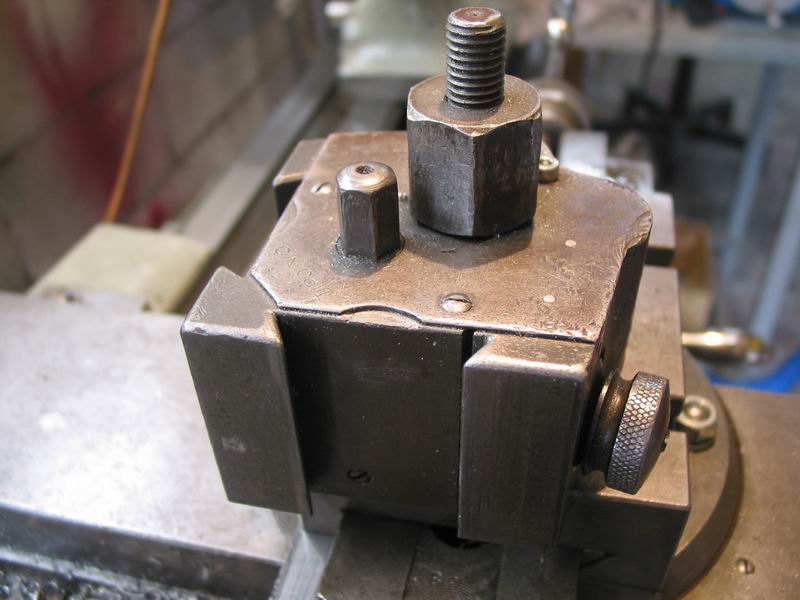

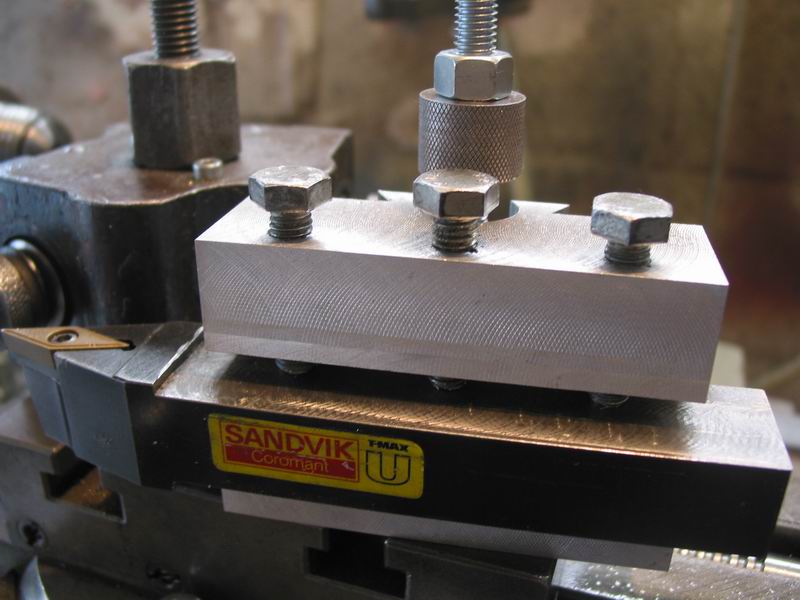

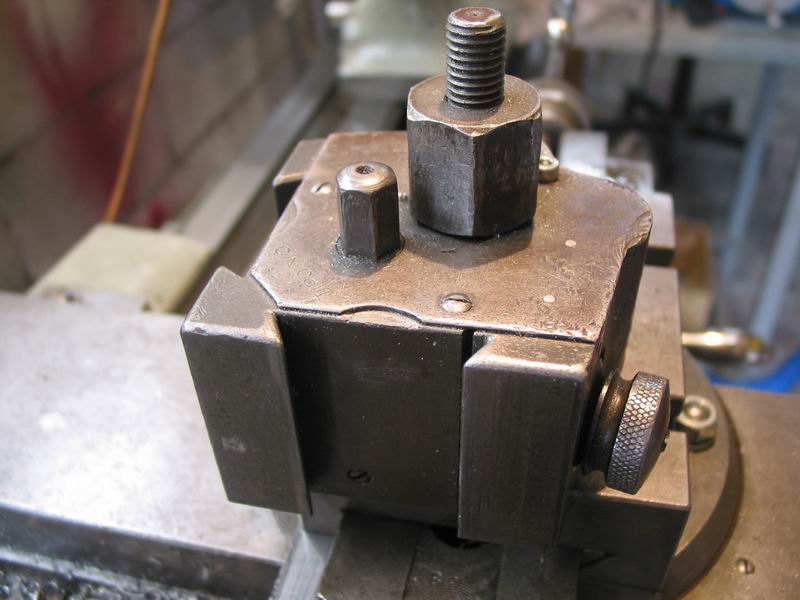

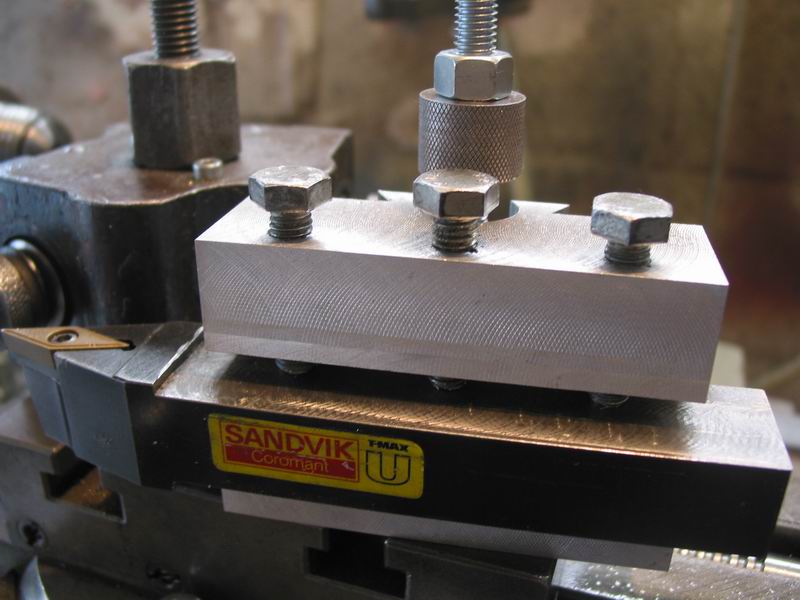

then I made 4 new tool holders for the very old QCTP of the Boley

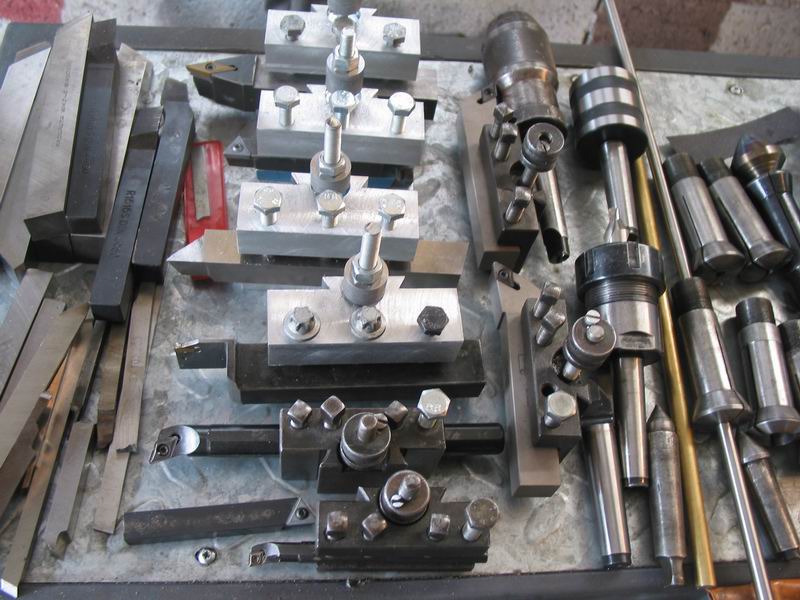

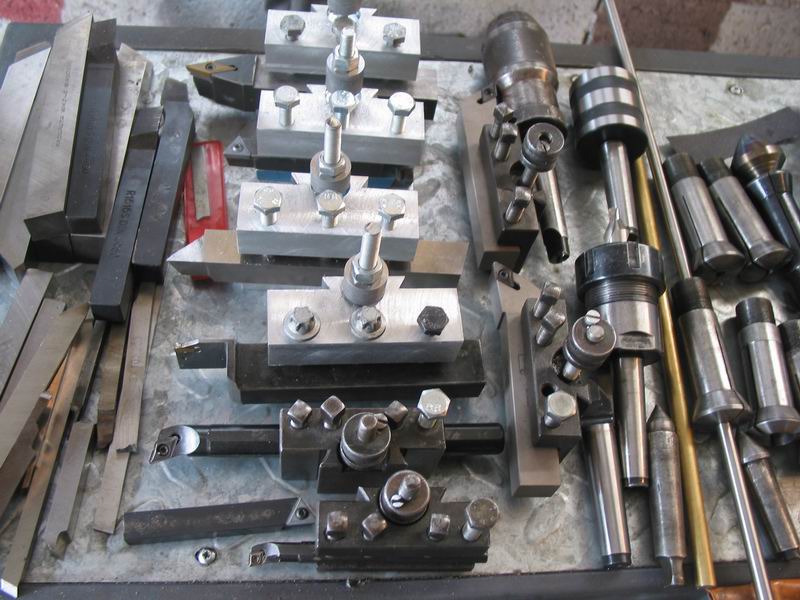

these are the 4 new holders, near the 4 old ones, for a total of 8 holders

I think that now, with 8 holders, about 30 collets and 5 chucks this section of the workshop would be ok (the tailstock has its appropriate tools too)

(the tailstock has its appropriate tools too)

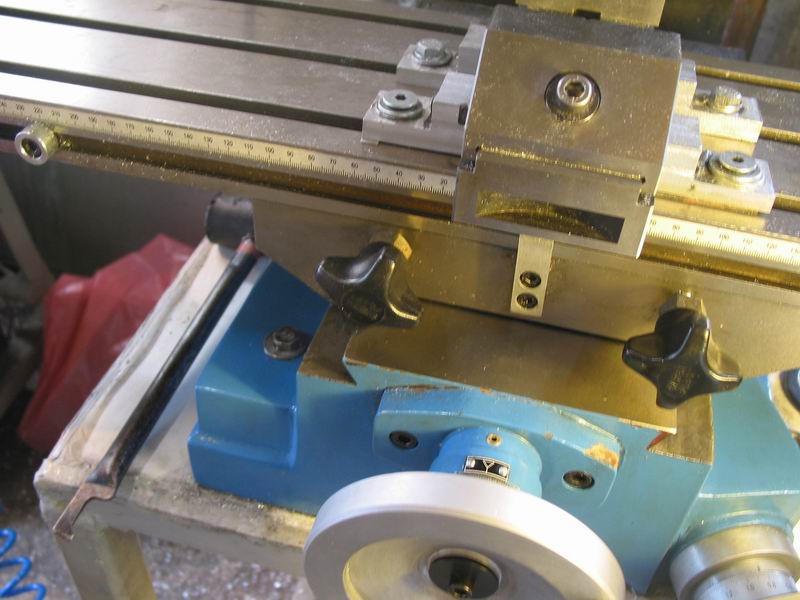

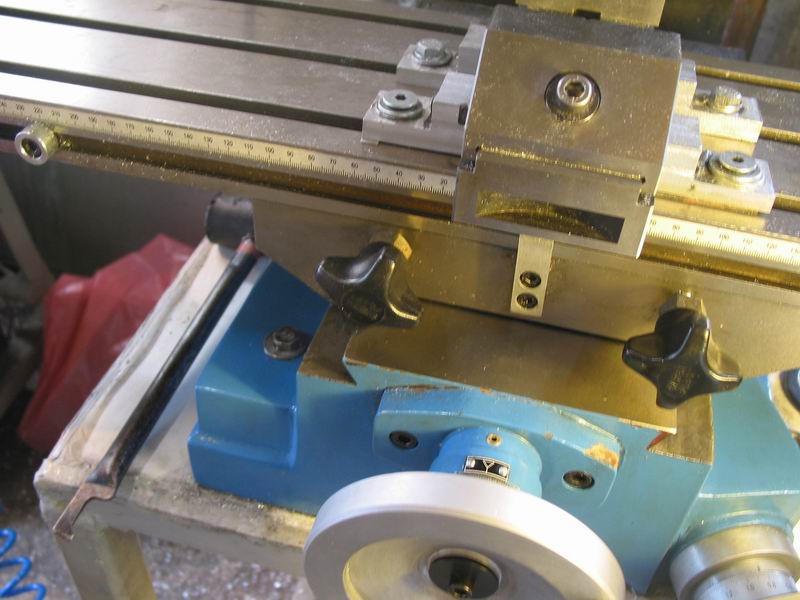

today I worked on the levers that block the longitudinal travel of the mill table. I broked them asap when the mill has arrived, because moving the table in traverse travel the factory levers touch the base of the mill if you are not careful and don't move them upward

I had some handle grips laying around in the shop and so today I modified them to be used instead of the original levers. here a pic

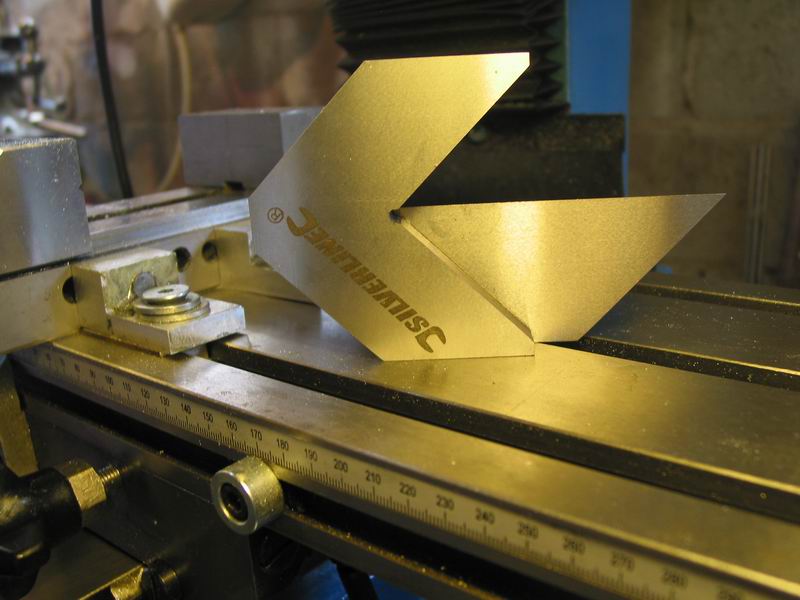

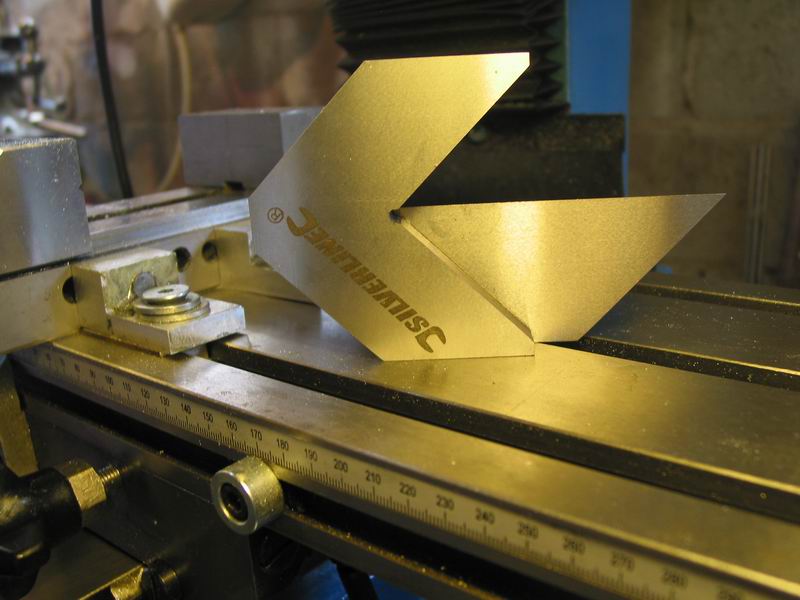

finally I wish to show you a nice tool that I bought recently. I have had always some difficulties to locate the centre of a rod, with the caliper that slips everywhere when I try to trace the necessary lines

with this tool the task is a joke

well, that's all folks

I hope to return soon at some serious work: engines!

meanwhile, I spent the last weeks upon little works in the shop

I had bought times ago a great backplate (200 mm) for a 160 mm lathe chuck, but I have never used it, because I mounted the chuck on another backplate

so in these days I have made a face plate with it. it is of cast iron, I brought down the diameter to about 180 mm, made the thread for the Boley spindle nose (40 x 3,5 mm) and worked the face of the plate

then I made 4 new tool holders for the very old QCTP of the Boley

these are the 4 new holders, near the 4 old ones, for a total of 8 holders

I think that now, with 8 holders, about 30 collets and 5 chucks this section of the workshop would be ok

today I worked on the levers that block the longitudinal travel of the mill table. I broked them asap when the mill has arrived, because moving the table in traverse travel the factory levers touch the base of the mill if you are not careful and don't move them upward

I had some handle grips laying around in the shop and so today I modified them to be used instead of the original levers. here a pic

finally I wish to show you a nice tool that I bought recently. I have had always some difficulties to locate the centre of a rod, with the caliper that slips everywhere when I try to trace the necessary lines

with this tool the task is a joke

well, that's all folks

I hope to return soon at some serious work: engines!