thezetecman

Active Member

- Joined

- Apr 30, 2008

- Messages

- 37

- Reaction score

- 0

Hi

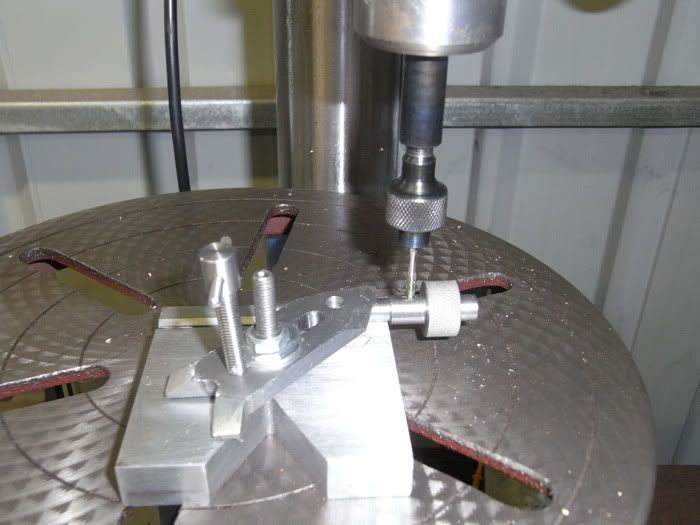

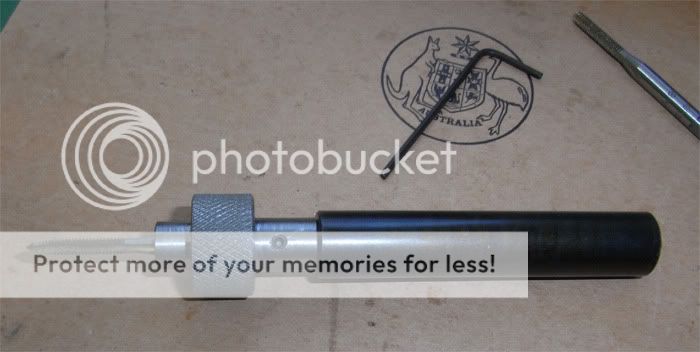

A few years ago I bought a Pollard made in Leicester corona high speed drill at an auction. It is a small bench drill very heavily built. probably weights 60 kg

The trouble is it has a 2850rpm motor fitted which means the minimum chuck speed is about 11400 rpm and the maximum speed is near to 15000.

Does this sound right?

I do not know what, other than PCB's what you would drill at those speeds.

I am thinking of changing the gearing to bring is down to about 4000 and 5000 rpm and add an electrical speed control giving a speed range of 2000 to 5000

Which I could use for drilling holes below 1mm in metal probably.

Has any one know what these were used for originally? or know anything about this drill I have searched the www and found nothing.

Thanks in advance for your comments?

A few years ago I bought a Pollard made in Leicester corona high speed drill at an auction. It is a small bench drill very heavily built. probably weights 60 kg

The trouble is it has a 2850rpm motor fitted which means the minimum chuck speed is about 11400 rpm and the maximum speed is near to 15000.

Does this sound right?

I do not know what, other than PCB's what you would drill at those speeds.

I am thinking of changing the gearing to bring is down to about 4000 and 5000 rpm and add an electrical speed control giving a speed range of 2000 to 5000

Which I could use for drilling holes below 1mm in metal probably.

Has any one know what these were used for originally? or know anything about this drill I have searched the www and found nothing.

Thanks in advance for your comments?