Cedge

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,730

- Reaction score

- 29

Being sort of between projects means I have time to try some of the strange ideas that come to me when I'm too busy with a build to stop. This little experiment was one such idea that kept bobbing to the top of the heap, so last evening I decided to give it free reign.

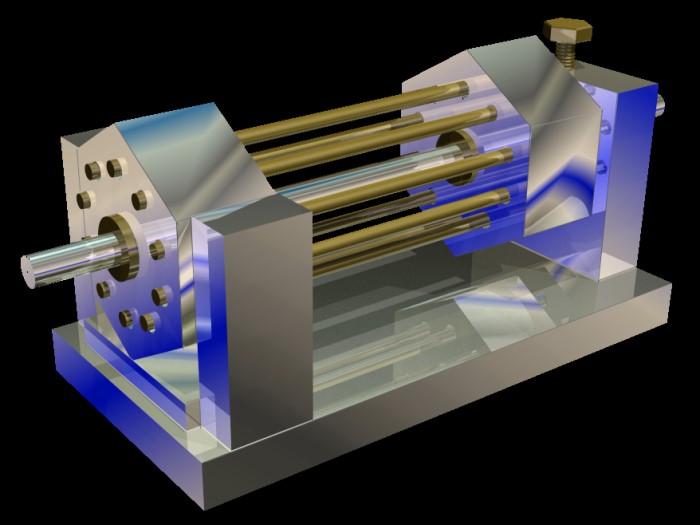

I'm about to begin Jerry Howells, "Miser" but want to change the look so that it's not like every other Miser one sees. Since the changes one can make are basically cosmetic and limited to areas like the column, the connecting rod and the smaller cylinders associated with the pistons.... Those are the places I'm looking to alter a bit.

Here is the result of my first attempt at a spiral fluted section which will likely become part of the main column. It consists of 10 pieces of .091 brass rod I had laying about. once twisted they were then soldered to make it all nice and rigid. The ends are simply something whipped out to give the column appearance.

Steve

I'm about to begin Jerry Howells, "Miser" but want to change the look so that it's not like every other Miser one sees. Since the changes one can make are basically cosmetic and limited to areas like the column, the connecting rod and the smaller cylinders associated with the pistons.... Those are the places I'm looking to alter a bit.

Here is the result of my first attempt at a spiral fluted section which will likely become part of the main column. It consists of 10 pieces of .091 brass rod I had laying about. once twisted they were then soldered to make it all nice and rigid. The ends are simply something whipped out to give the column appearance.

Steve