Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

[FONT="]Shortly after getting my Grizzly 10 x 22 lathe 6 years ago I looked for a collet closer for it. There was none to be found. The benefits of using a collet to hold work have been stated here many times so I wont repeat them.[/FONT]

[FONT="]I recently became aware of an ER collet chuck with a MT-4 tapered shank, which is the spindle taper on the Grizzly. [/FONT]

[FONT="]This chuck was bundled with collets ranging from 1/8 1 in 1/32. For perspective, industry quality ER-40 collets can cost $30 USD each and Im getting 23 of them, a collet chuck, a wrench for less than $200 USD. So I knew I was taking a chance. [/FONT]

[FONT="]A 5/8 11 thread is used for a drawbar to hold the chuck. I used a piece of allthread I had on hand and made a spindle nose protector using a 1 ¾ 8 hex nut. I drilled the nut for a tommy bar to assist popping the chuck free of the spindle.[/FONT]

[FONT="]

[/FONT]

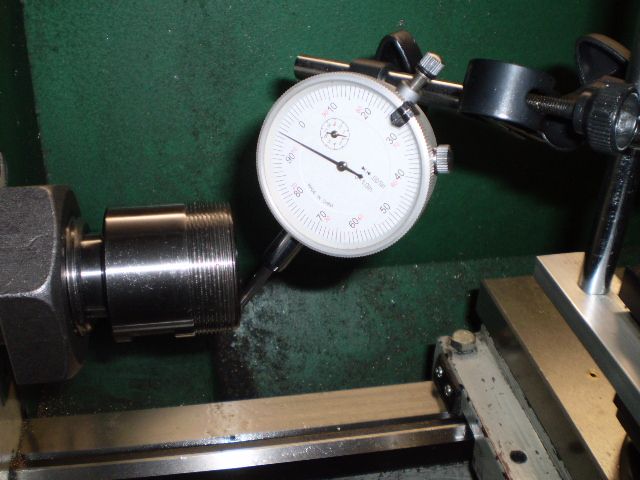

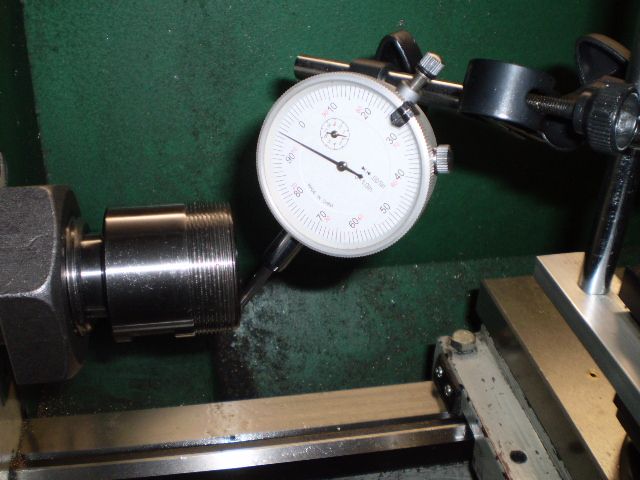

[FONT="]I couldnt measure the needle deflection when the spindle was rotated, so it was probably less than a few tenths of a thou. This was very encouraging. [/FONT]

[FONT="]

[/FONT]

[FONT="]I decided to make a spare valve for the IC engine Im building. The valve face is 0.375 diameter and the valve stem is 0.124 with a 4-40 threaded end with an overall length of about 1.5. Starting with 3/8 stainless rod, I turned the stem down to 0.110 for a length of 3/8 and threaded that 4-40. Then I turned the stem down to 0.124 in three steps each of 3/8 length. The junctions of the last 3 steps are nearly seamless under magnification. I did not need to use a file or sandpaper on the stem.

[/FONT]

[FONT="]

[/FONT]

[FONT="]My conclusion is favorable. This tool does what I needed to do and is a good choice for those lathes with an MT4 spindle taper. Just be aware that the drawbar will limit your ability to pass long pieces of stock through the spindle.

[/FONT]

[FONT="]I purchased the chuck from an eBay vendor. Just search for MT4 and ER collet chuck. The vendor with the Germanic sounding name is the guy. I have no affiliation with him, just a satisfied customer.[/FONT]

[FONT="]Cheers,[/FONT]

[FONT="]Phil[/FONT]

[FONT="]I recently became aware of an ER collet chuck with a MT-4 tapered shank, which is the spindle taper on the Grizzly. [/FONT]

[FONT="]This chuck was bundled with collets ranging from 1/8 1 in 1/32. For perspective, industry quality ER-40 collets can cost $30 USD each and Im getting 23 of them, a collet chuck, a wrench for less than $200 USD. So I knew I was taking a chance. [/FONT]

[FONT="]A 5/8 11 thread is used for a drawbar to hold the chuck. I used a piece of allthread I had on hand and made a spindle nose protector using a 1 ¾ 8 hex nut. I drilled the nut for a tommy bar to assist popping the chuck free of the spindle.[/FONT]

[FONT="]

[/FONT]

[FONT="]I couldnt measure the needle deflection when the spindle was rotated, so it was probably less than a few tenths of a thou. This was very encouraging. [/FONT]

[FONT="]

[/FONT]

[FONT="]I decided to make a spare valve for the IC engine Im building. The valve face is 0.375 diameter and the valve stem is 0.124 with a 4-40 threaded end with an overall length of about 1.5. Starting with 3/8 stainless rod, I turned the stem down to 0.110 for a length of 3/8 and threaded that 4-40. Then I turned the stem down to 0.124 in three steps each of 3/8 length. The junctions of the last 3 steps are nearly seamless under magnification. I did not need to use a file or sandpaper on the stem.

[/FONT]

[FONT="]

[/FONT]

[FONT="]My conclusion is favorable. This tool does what I needed to do and is a good choice for those lathes with an MT4 spindle taper. Just be aware that the drawbar will limit your ability to pass long pieces of stock through the spindle.

[/FONT]

[FONT="]I purchased the chuck from an eBay vendor. Just search for MT4 and ER collet chuck. The vendor with the Germanic sounding name is the guy. I have no affiliation with him, just a satisfied customer.[/FONT]

[FONT="]Cheers,[/FONT]

[FONT="]Phil[/FONT]