- Joined

- Jan 19, 2010

- Messages

- 1,193

- Reaction score

- 41

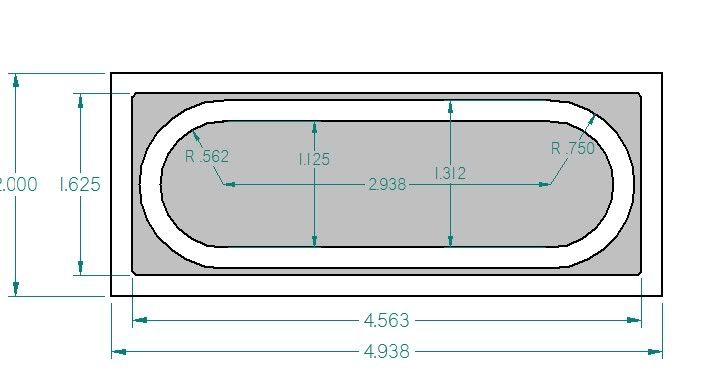

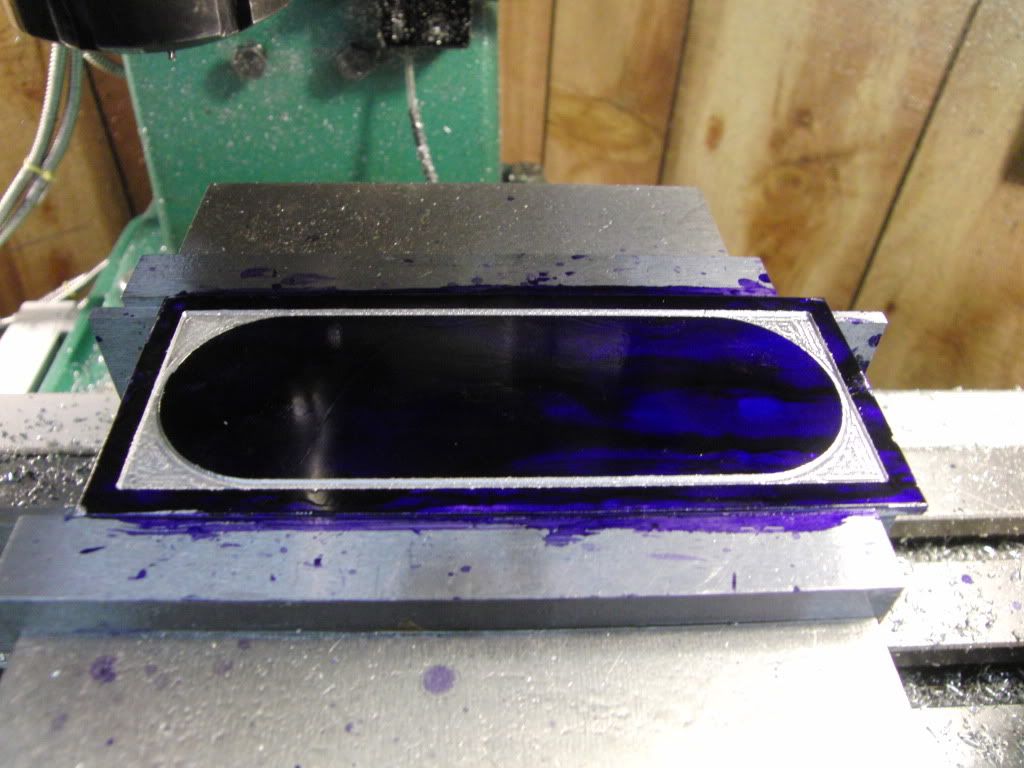

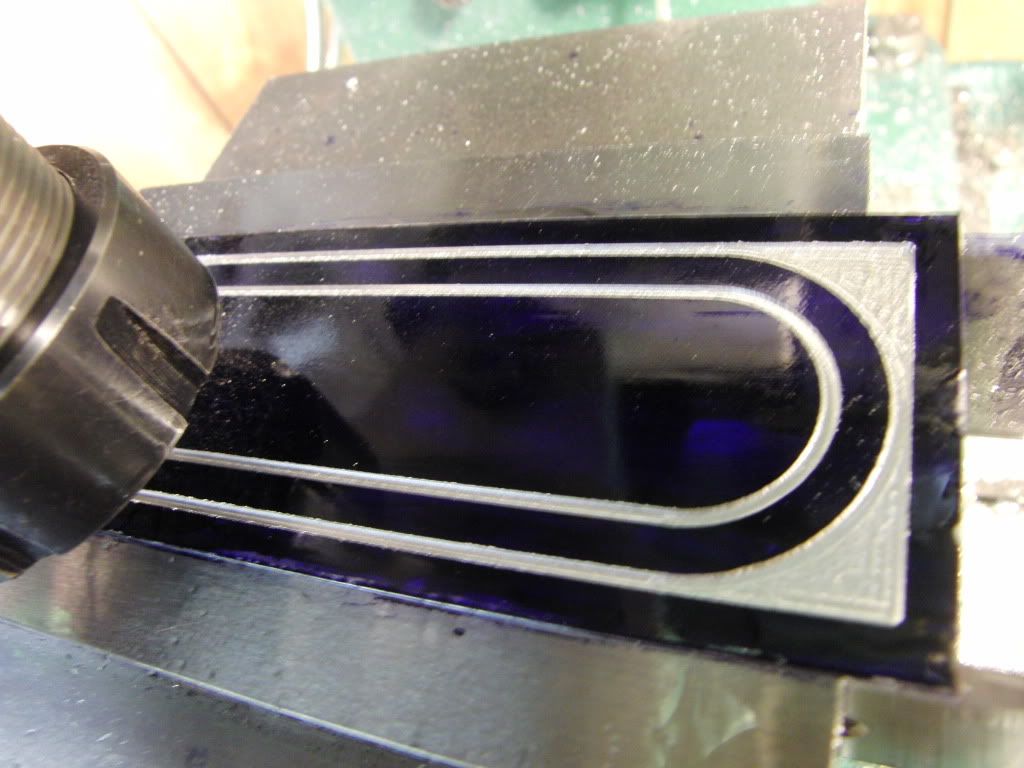

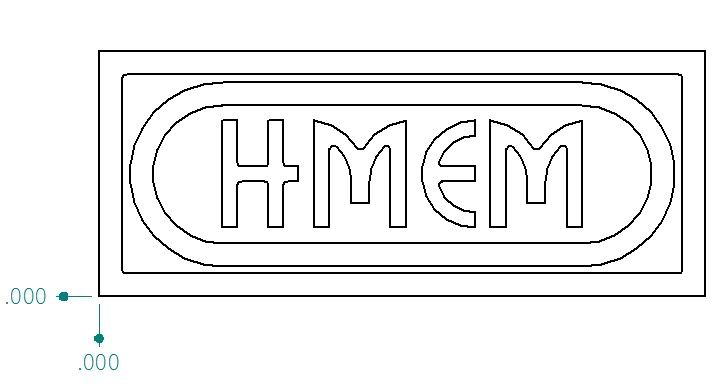

I recently Discovered I could make engrave letters or other complex round or angled shapes using my Computerized DRO. So I thought I would share exactly how I did it.

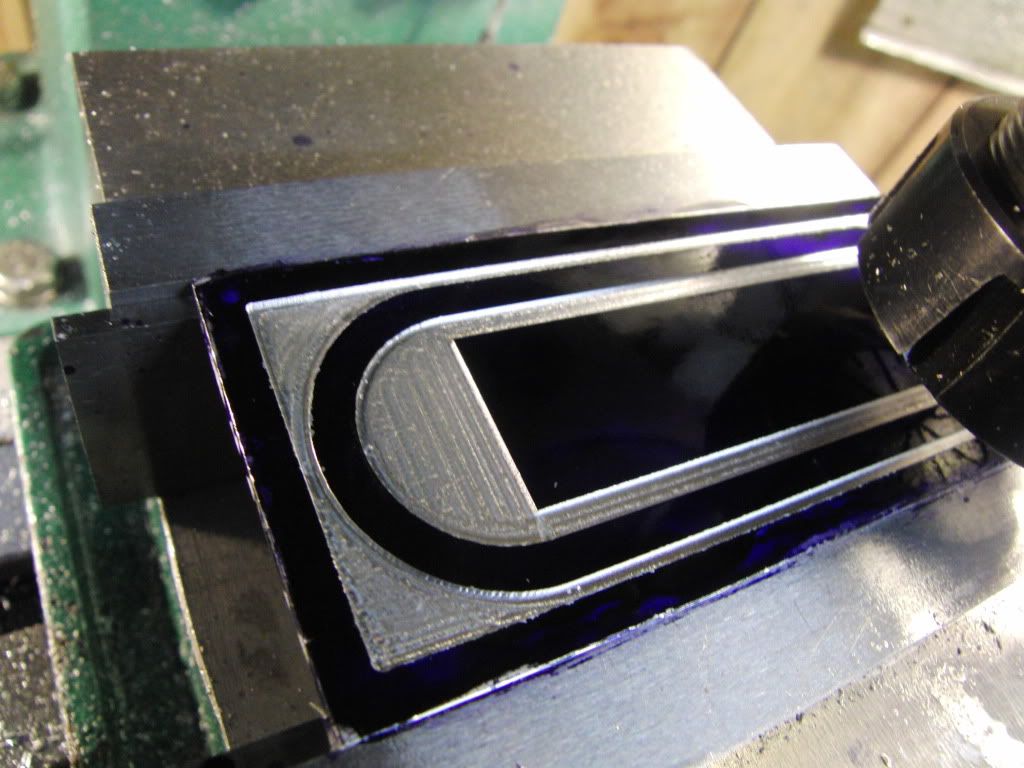

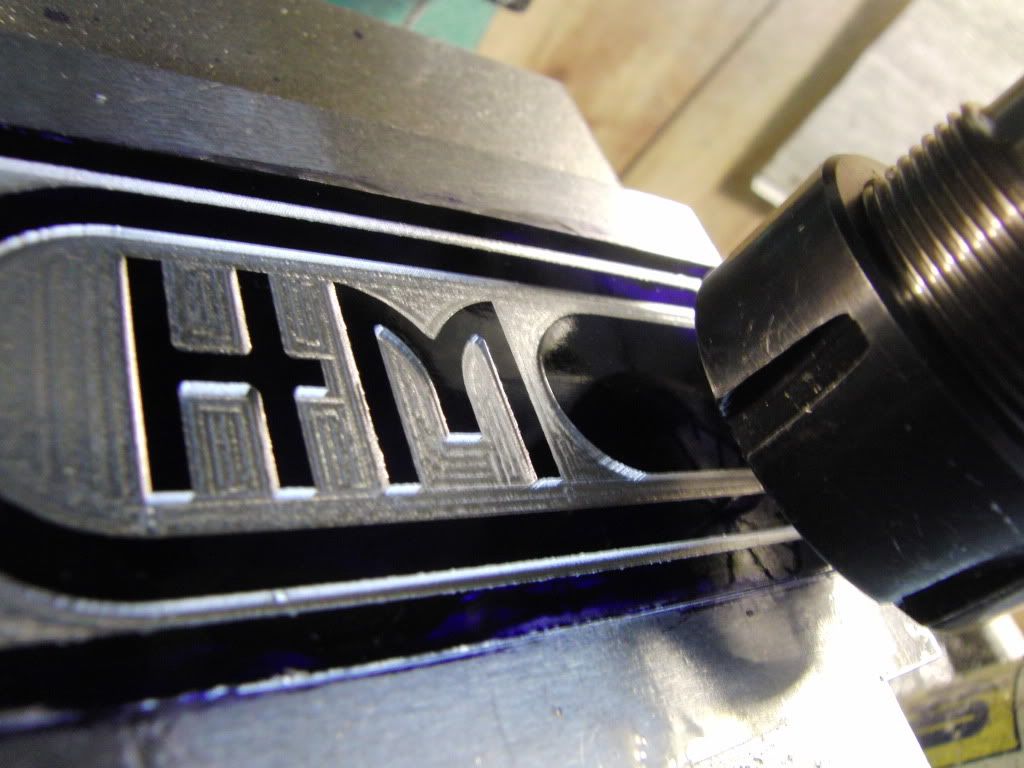

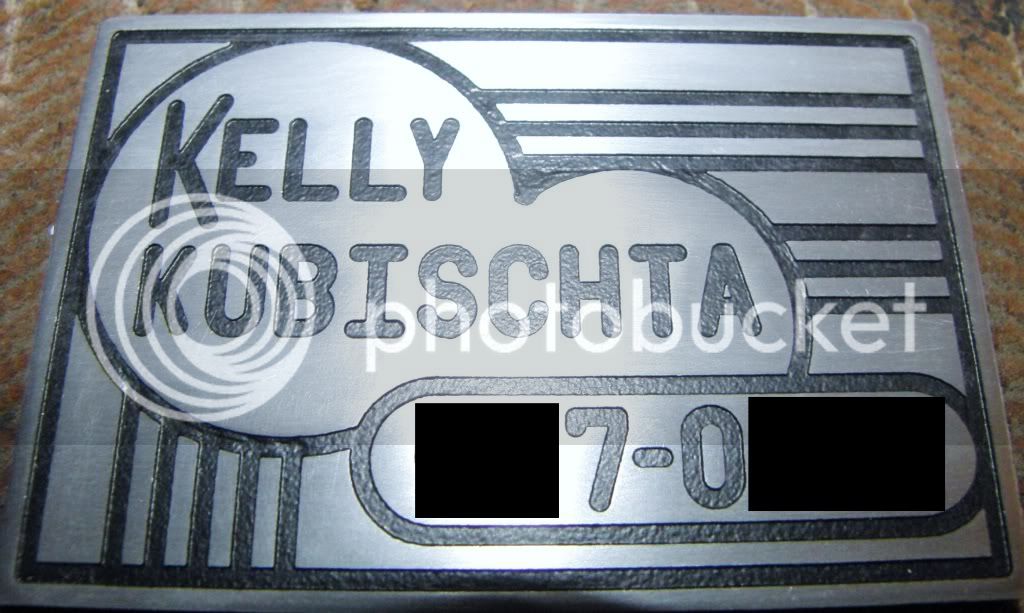

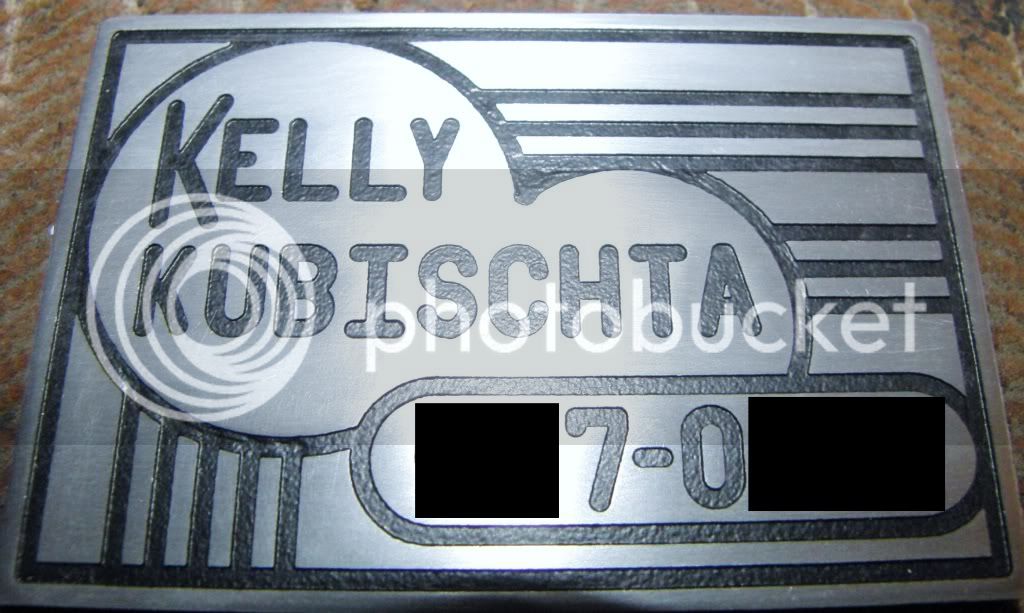

Here are a couple examples of what I have done so far.

I am going to do this in a few installments, and try to cover as much as I can.

Firstly I am using a DRO with computer functions like inclined, and radius milling. This could be accomplished without a DRO using mathematical formulas and a notebook full of Co-Ordinance's, or even a rotary table and an angled vice, but for now a DRO is the easiest way.

To Begin I will show you how I draw the letters. It is important to know the layout of the letters before you start thinking about milling them.

Drawing the letters is a pretty straight forward process.

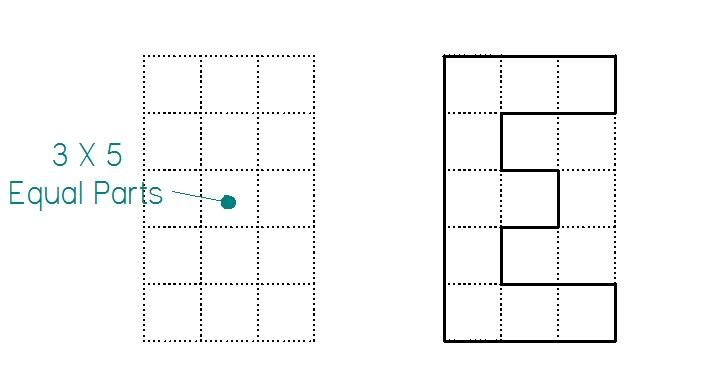

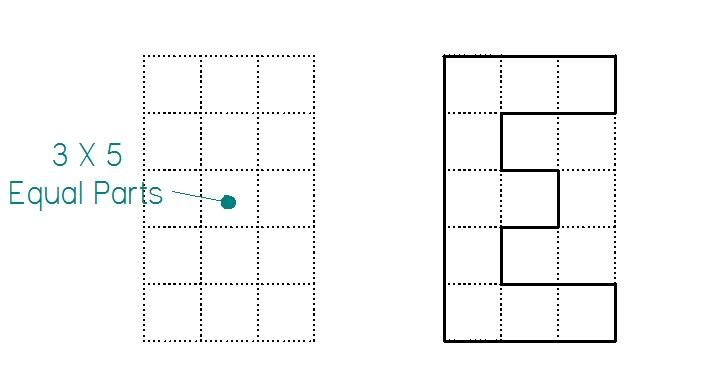

Virtually all letters and numbers, aside from M and W, can be drawn in a 3 accross by 5 high grid.

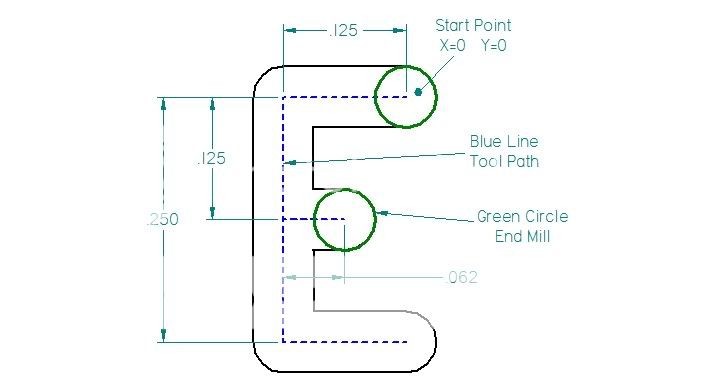

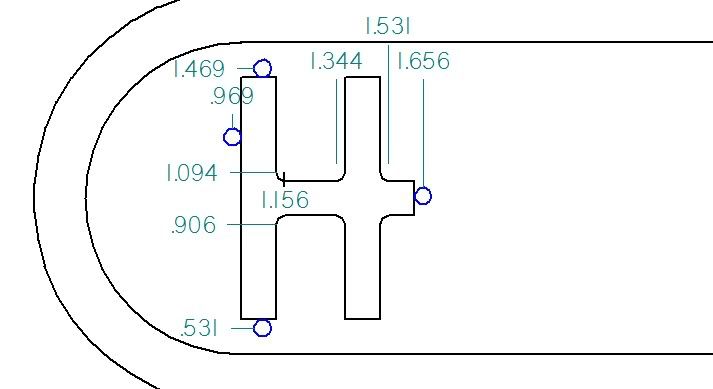

There are a lot of easy letters to make like E, H, T, and all the straight ones. Here is an example of an E drawn in a 3 X 5 grid. This grid I am using is made up of 1/8" X 1/8" squares. This will make 1/8" lines. You can do this on graph paper, but using a 2D drafting program makes it a lot easier to draw up, and figure out the positions of cutter in relation to the letter. I am using Solid Edge 2D, it is a free download and a complete version, no restrictions, verry easy to use, and makes finding hidden dimensions a breeze.

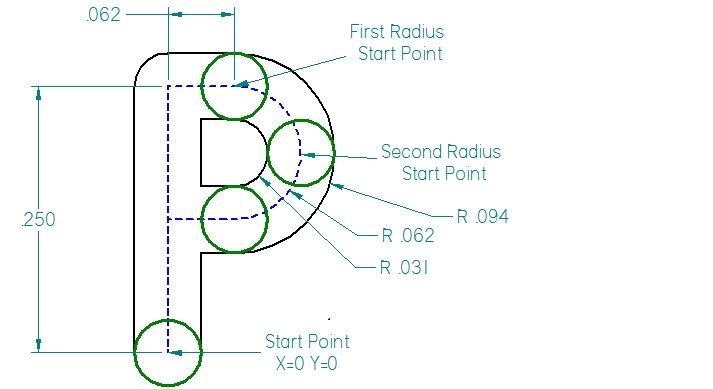

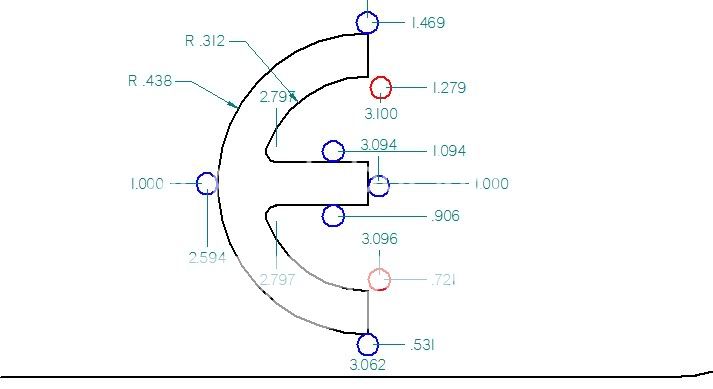

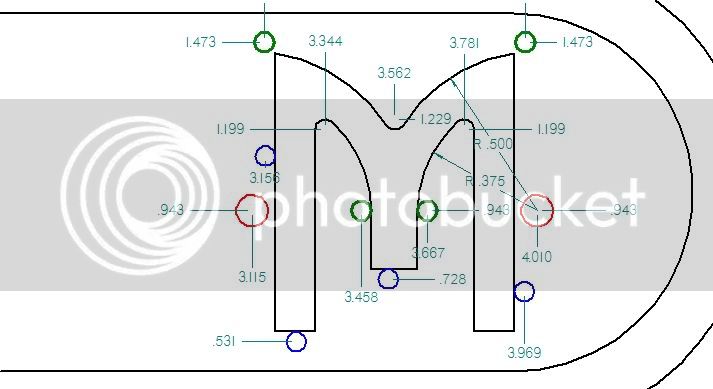

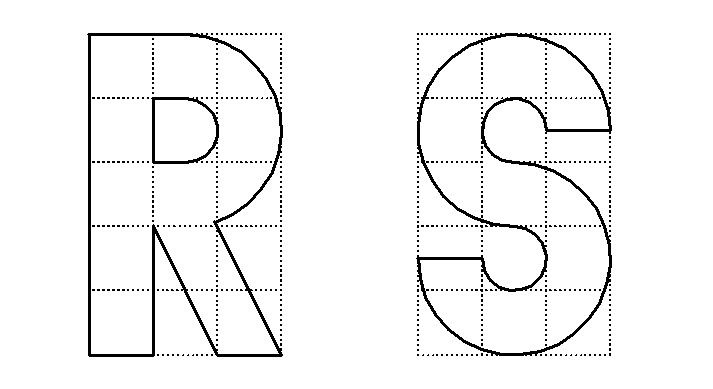

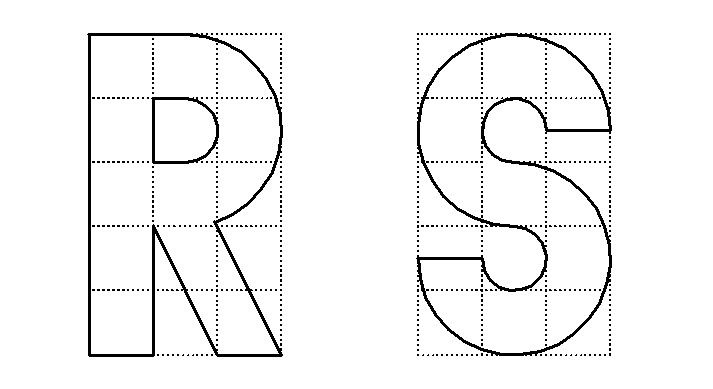

The more complex letters are also drawn out in the same fashion. The radii of the circular sides are the same as 1/2 of the width of the Grid, in this case its 3/16"

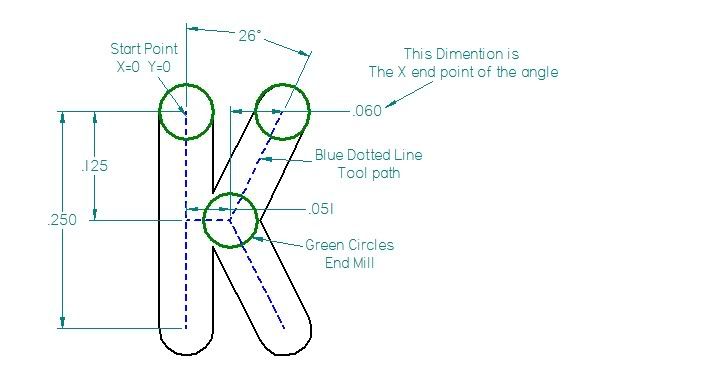

The S consists of two 3/4 circles connected in the middle. An the R includes a 20 degree angle which connects at the circle. When you draw up your letters you will have to account for the width of the cutter you will be using, and you will have to play with angles to get the shape you are looking for. I will go into more depth on this later, this is just to get you familiar with the drawing process of letters.

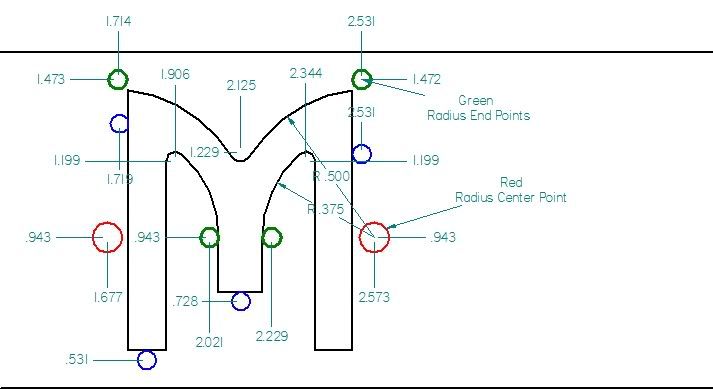

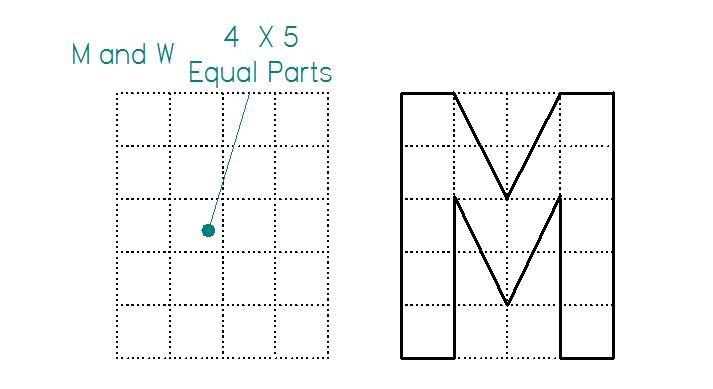

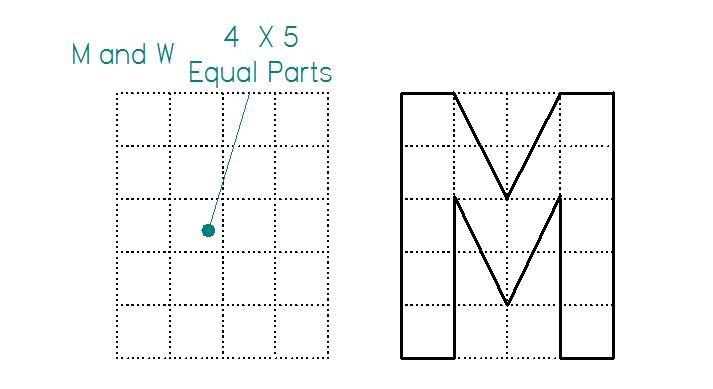

I mentioned earlier that the M and W would require a different grid, Here is a drawing of a W on a 4 X 5 grid. These letters are more stretched out than the rest.

So, thats it for the simple drawing of the letters. Next I will go into depth on accounting for cutter diameter when milling the letters.

Kel

Here are a couple examples of what I have done so far.

I am going to do this in a few installments, and try to cover as much as I can.

Firstly I am using a DRO with computer functions like inclined, and radius milling. This could be accomplished without a DRO using mathematical formulas and a notebook full of Co-Ordinance's, or even a rotary table and an angled vice, but for now a DRO is the easiest way.

To Begin I will show you how I draw the letters. It is important to know the layout of the letters before you start thinking about milling them.

Drawing the letters is a pretty straight forward process.

Virtually all letters and numbers, aside from M and W, can be drawn in a 3 accross by 5 high grid.

There are a lot of easy letters to make like E, H, T, and all the straight ones. Here is an example of an E drawn in a 3 X 5 grid. This grid I am using is made up of 1/8" X 1/8" squares. This will make 1/8" lines. You can do this on graph paper, but using a 2D drafting program makes it a lot easier to draw up, and figure out the positions of cutter in relation to the letter. I am using Solid Edge 2D, it is a free download and a complete version, no restrictions, verry easy to use, and makes finding hidden dimensions a breeze.

The more complex letters are also drawn out in the same fashion. The radii of the circular sides are the same as 1/2 of the width of the Grid, in this case its 3/16"

The S consists of two 3/4 circles connected in the middle. An the R includes a 20 degree angle which connects at the circle. When you draw up your letters you will have to account for the width of the cutter you will be using, and you will have to play with angles to get the shape you are looking for. I will go into more depth on this later, this is just to get you familiar with the drawing process of letters.

I mentioned earlier that the M and W would require a different grid, Here is a drawing of a W on a 4 X 5 grid. These letters are more stretched out than the rest.

So, thats it for the simple drawing of the letters. Next I will go into depth on accounting for cutter diameter when milling the letters.

Kel