Oldmechthings

Well-Known Member

- Joined

- Jan 10, 2008

- Messages

- 153

- Reaction score

- 12

Below is a picture of my first attempt at building a Gasoline engine. My friend Lawrence Jordan had bought a casting kit, and before starting to work on it, he dropped it of so I could use the castings as patterns to make my own. It required making up a core box, but that was still a lot less effort than starting right from scratch.

Economy engines were built by Hercules engine company, and were sold by Sears Roebuck under the Economy name. Hercules also built the Jager engines that were put on Jager cement mixers.

For this little engine I even built my own spark plug using Coran as an insulator. People marvel at that, but the spark plug was much simpler to build than the drip oiler up on top. It is equipped with a miniature homemade buzz coil, built from the magneto out of a lawn mower type engine. It works like the old model T Ford coils. It can run off a flashlight battery. Construction details were sent in and published in both Gas Engine, and Modeltec magazines.

Lawrence Jordan, I believe would be classified as a heavy duty mechanic! He had worked at the Ironton plant between Provo and Springville. That was a facility, which is now just history, that took iron ore from southern Utah, coal from eastern Utah and locally quarried limestone and produced pig iron. The pig iron was then marketed to iron foundries. By todays standards it was ancient. It had steam engines to power the skip hoists the run the material up to be dumped into the blast furnaces. And it had huge steam powered blowing engines to provide air to the blast furnaces. Lawrence gave me a couple pictures one day.

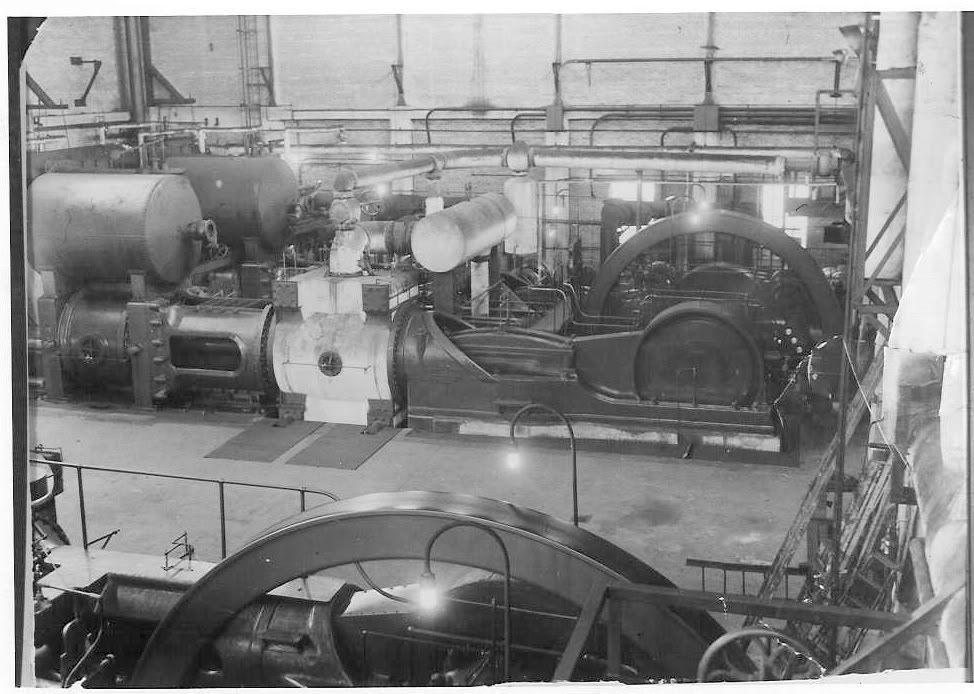

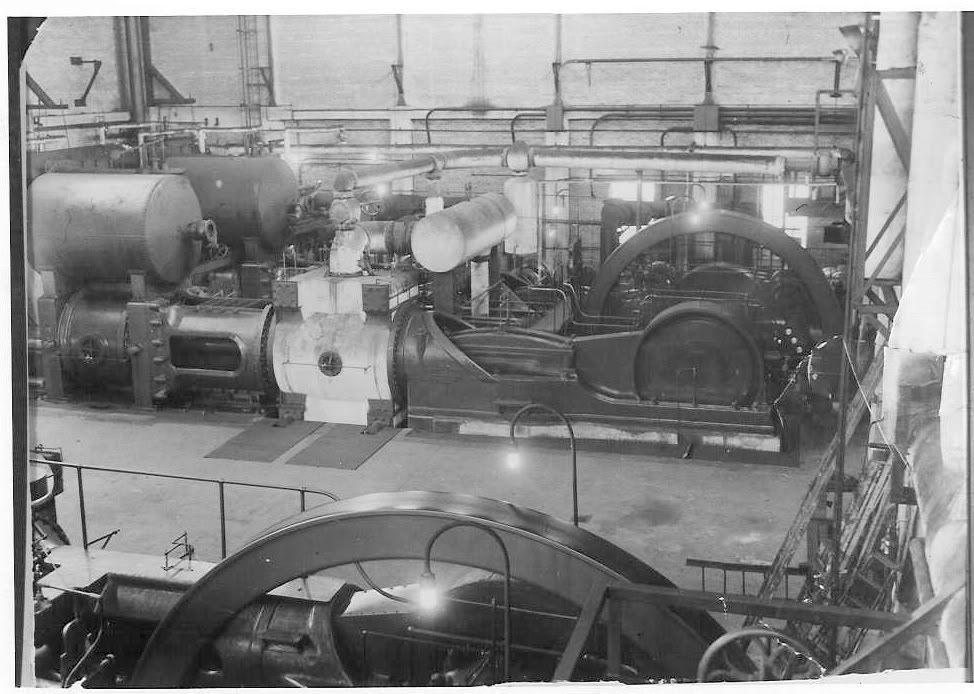

Two engines were horizontal. To give you an idea of their size, that building is 80 feet wide. Lawrence told me of taking a manhole cover off the side of the engine, crawling inside the cylinder and sitting on the piston rod while changing the valves. Note that you cannot see the spokes in the flywheels, the engines were running as the picture was taken.

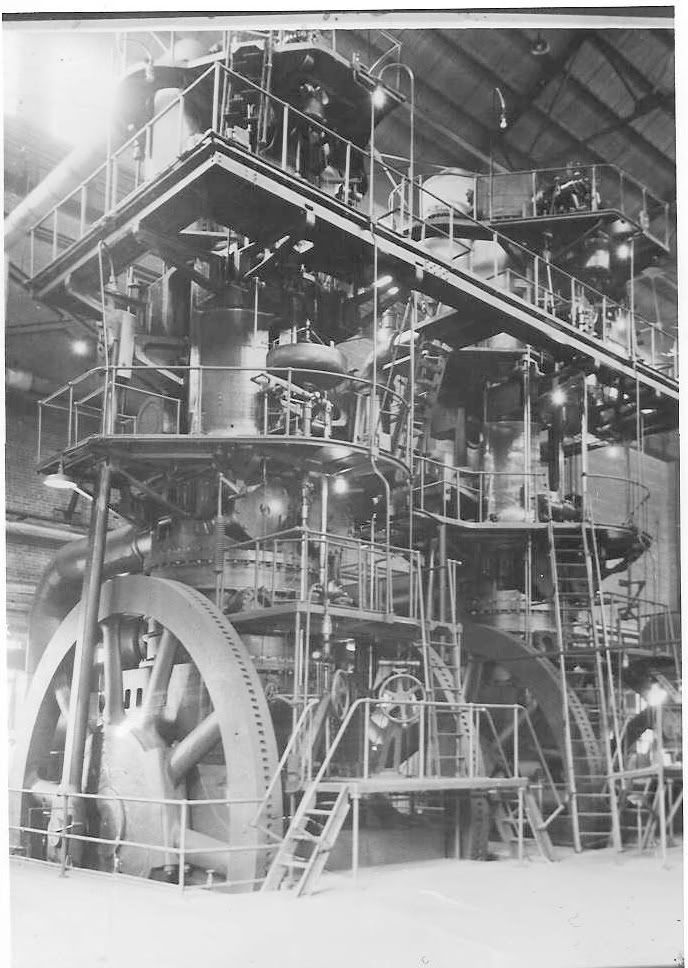

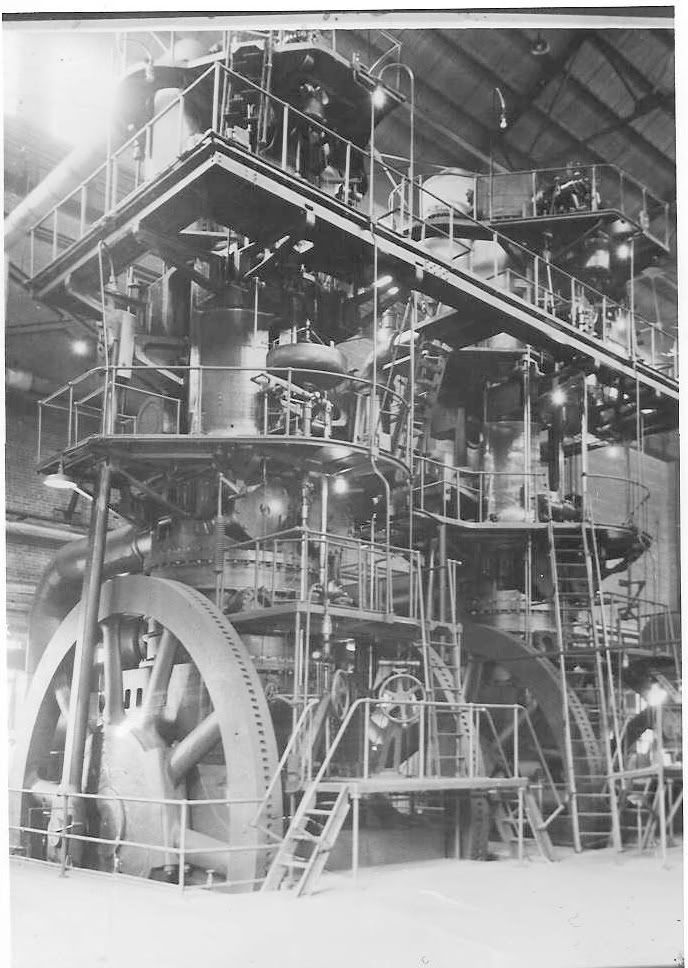

Two other engines were of the vertical type, I measured the flywheels once while at the plant, and they were 22 feet diameter. Lawrence told me of an occasion one time when the top end of one of these engines broke or blew off, and came tumbling to the floor. No one was hurt, but he said it was quite a task getting it repaired and back together again.

If some of the viewers would like an interesting challenge, here are a couple steam engine designs, that I do not remember seeing models of. Here is your chance!

Birk

Economy engines were built by Hercules engine company, and were sold by Sears Roebuck under the Economy name. Hercules also built the Jager engines that were put on Jager cement mixers.

For this little engine I even built my own spark plug using Coran as an insulator. People marvel at that, but the spark plug was much simpler to build than the drip oiler up on top. It is equipped with a miniature homemade buzz coil, built from the magneto out of a lawn mower type engine. It works like the old model T Ford coils. It can run off a flashlight battery. Construction details were sent in and published in both Gas Engine, and Modeltec magazines.

Lawrence Jordan, I believe would be classified as a heavy duty mechanic! He had worked at the Ironton plant between Provo and Springville. That was a facility, which is now just history, that took iron ore from southern Utah, coal from eastern Utah and locally quarried limestone and produced pig iron. The pig iron was then marketed to iron foundries. By todays standards it was ancient. It had steam engines to power the skip hoists the run the material up to be dumped into the blast furnaces. And it had huge steam powered blowing engines to provide air to the blast furnaces. Lawrence gave me a couple pictures one day.

Two engines were horizontal. To give you an idea of their size, that building is 80 feet wide. Lawrence told me of taking a manhole cover off the side of the engine, crawling inside the cylinder and sitting on the piston rod while changing the valves. Note that you cannot see the spokes in the flywheels, the engines were running as the picture was taken.

Two other engines were of the vertical type, I measured the flywheels once while at the plant, and they were 22 feet diameter. Lawrence told me of an occasion one time when the top end of one of these engines broke or blew off, and came tumbling to the floor. No one was hurt, but he said it was quite a task getting it repaired and back together again.

If some of the viewers would like an interesting challenge, here are a couple steam engine designs, that I do not remember seeing models of. Here is your chance!

Birk