Naiveambition

Well-Known Member

- Joined

- May 15, 2012

- Messages

- 369

- Reaction score

- 95

Alright I've had enough!! I've been looking into a dro system for my zx45 mill. Been all over the net reading info, and as usual it is a cluster bomb of info that is hard to understand.

So.... Is resolution just the amount of numbers on the screen that it is capable of reading.? Why would I need tenths if my mill won't do it. I seem to be happy if I can hit the thousandths with a zero.

Most systems seem to offer different resolutions, so if I can change it, where does my repeatability come in to play. Some state that glass scales are in the .001 area. Why would I need glass scales if the simple caliper style like igaging also state .001 accuracy. .002 over six inches seems really bad to me. As most of you know this is enough to make or break a slip fit.

I know that my machine is not the most accurate mill, but if I add dro error to the mix, it just seems to make the case worse.

As of now I'm looking at a dro pros kit. I like the price point, but even more expensive systems offer the same resolution numbers. Am I missing something here?

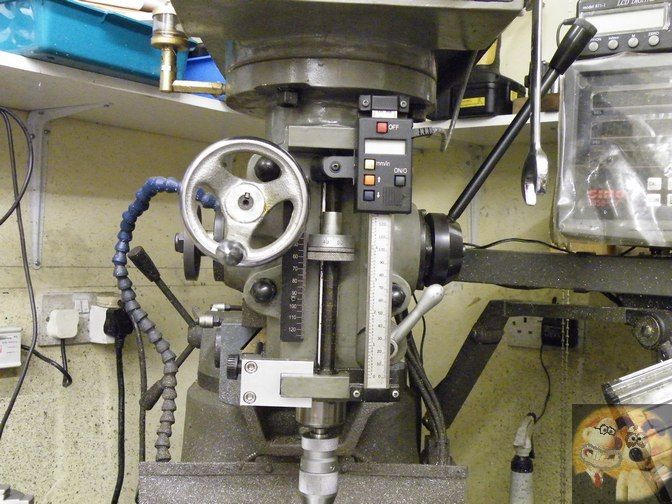

I would like a 3 axis kit but doesn't seem to be appropriate for my style of mill. So i am looking at a 2 axis kit for the table and a mitoyo vertical scale for my z axis.

I'm not keen on the many options for mounting glass scales. Don't know part name but the huge part at the bottom of the quill attached to my depth stop :hDe: Is always in the way. Especially when using rotary table in vertical position, so with the many options for mounting dro scales just seems to complicate this problem.

I would love for someone to explain in laymens terms what I'm looking at. Meaning if your family member asked the same .?s you would say this is what you need and don't mess with this one blah blah blah...

So.... Is resolution just the amount of numbers on the screen that it is capable of reading.? Why would I need tenths if my mill won't do it. I seem to be happy if I can hit the thousandths with a zero.

Most systems seem to offer different resolutions, so if I can change it, where does my repeatability come in to play. Some state that glass scales are in the .001 area. Why would I need glass scales if the simple caliper style like igaging also state .001 accuracy. .002 over six inches seems really bad to me. As most of you know this is enough to make or break a slip fit.

I know that my machine is not the most accurate mill, but if I add dro error to the mix, it just seems to make the case worse.

As of now I'm looking at a dro pros kit. I like the price point, but even more expensive systems offer the same resolution numbers. Am I missing something here?

I would like a 3 axis kit but doesn't seem to be appropriate for my style of mill. So i am looking at a 2 axis kit for the table and a mitoyo vertical scale for my z axis.

I'm not keen on the many options for mounting glass scales. Don't know part name but the huge part at the bottom of the quill attached to my depth stop :hDe: Is always in the way. Especially when using rotary table in vertical position, so with the many options for mounting dro scales just seems to complicate this problem.

I would love for someone to explain in laymens terms what I'm looking at. Meaning if your family member asked the same .?s you would say this is what you need and don't mess with this one blah blah blah...