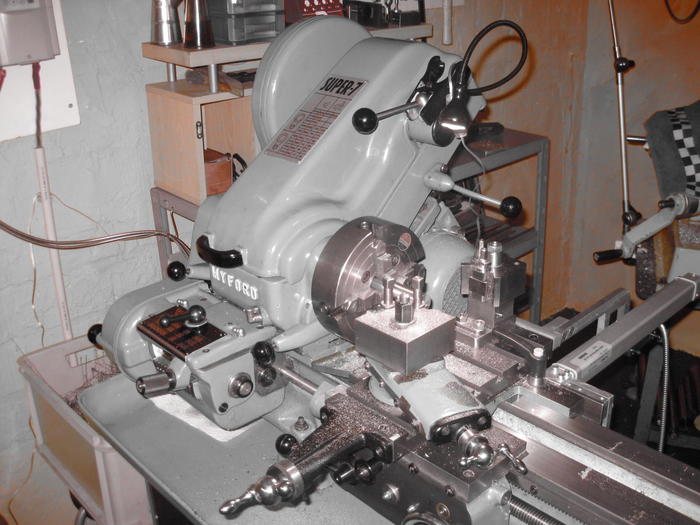

One of the challenges of retrofitting older machines w/DRO is the shape of the bed castings and lack of space on the cross slide. I'm not familiar with the Delta, but many older machines have a curvy art-deco casting shape that leaves no obvious planar location to mount the scales. I managed with an old Hardinge HLV-B that has a bed casting that is all curves, everywhere! It can be done. ;D

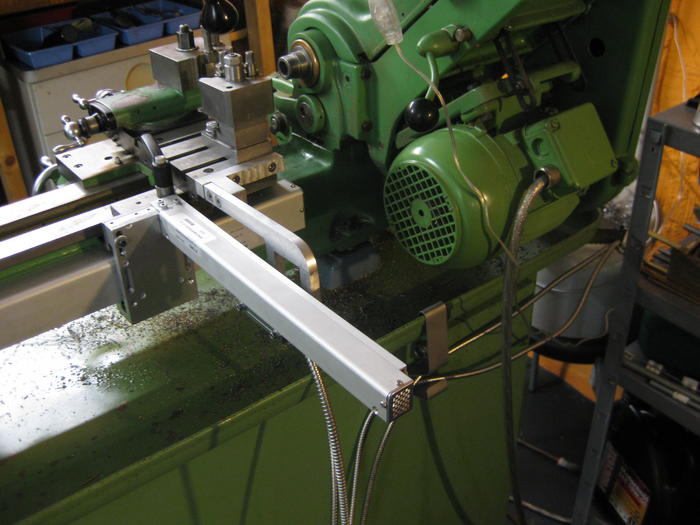

If you opt for the more accurate glass scales, have a plan in mind for the mounting. It can be tricky. One of the better plans is to mount an aluminum bracket or extrusion to the lathe which will ultimately have the scale mounted to IT. The aluminum bracket can use a heavy cap screw at each end for main attachment, and a pair of long set screws (say #6 or #8) to adjust the cant or alignment of the bracket. When parallel and true, mount your scale.

Or... "pads" can be built up of some composite material, like epoxy w/glass fibers or similar, so as to create a proper mount. Just be sure the pads won't degrade with oils and age.

Of the two, I like the notion of a bracket better. Good luck!