Can I ask a stupid question? What IS a "D" bit? I keep seeing it mentioned and when I search "D bit" you can guess how many hits I get. :'( Every post has a letter "D" in it. A link to a picture would be great. This has been bugging me for weeks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

"D" bit

- Thread starter BigBore

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

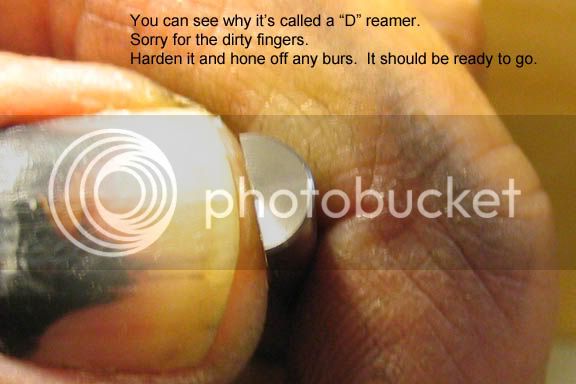

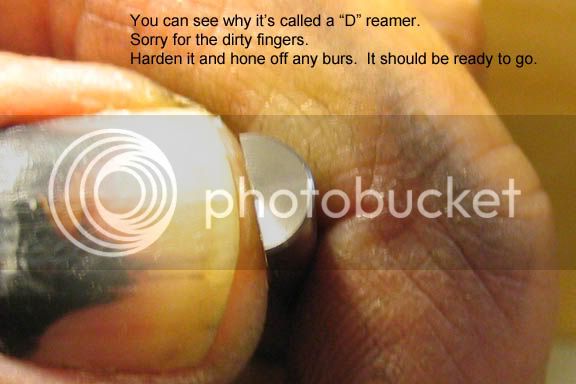

I expect you mean a D reamer.

A reamer made from drill rod. Usually, you use the same size drill rod that you want for your reamed hole. The end of the piece is milled off for a short distance, usually about equal to the diameter of the rod. Milling 1/2" of it away makes it resemble the letter "D" when viewed from the end. Another way to make one is to take a slice off the end at an angle, to form a kind of lozenge shape.

Dean

A reamer made from drill rod. Usually, you use the same size drill rod that you want for your reamed hole. The end of the piece is milled off for a short distance, usually about equal to the diameter of the rod. Milling 1/2" of it away makes it resemble the letter "D" when viewed from the end. Another way to make one is to take a slice off the end at an angle, to form a kind of lozenge shape.

Dean

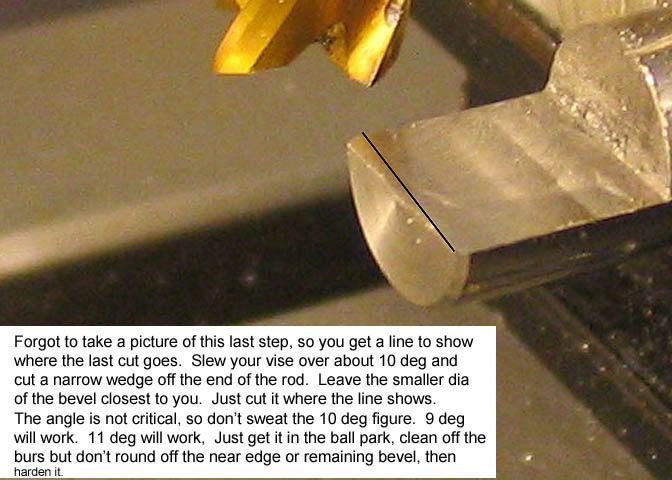

Here a pic that was made for another post, but will do for a quick look see.

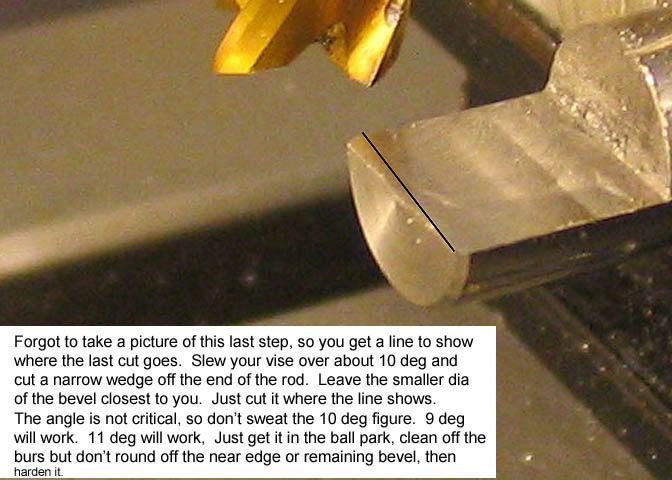

I didn't have a picture of it, but it should have a slight angle put on the front edge, too.

Here's another shot I found of the same reamer. Maybe will help explain a bit more.

I think I made these for Zee, but he doesn't want to know about it, so, shhhh...

Dean

I didn't have a picture of it, but it should have a slight angle put on the front edge, too.

Here's another shot I found of the same reamer. Maybe will help explain a bit more.

I think I made these for Zee, but he doesn't want to know about it, so, shhhh...

Dean

OK, I think I got the picture. I would imagine they have to be clamped in the tool holder with an over hang that is short as possible to prevent wobble? Also I assume you drill with a bit to a very close diameter first. How much can one of these take off. I suppose a slight chamfer of the hole would help guide the D reamer in?

Artwork, Tel? At first glance, I thought that was an expensive CAD drawing! : Hey, it worked, I got the point.

Hey, it worked, I got the point.

Artwork, Tel? At first glance, I thought that was an expensive CAD drawing! :

Twmaster

Well-Known Member

- Joined

- Oct 24, 2009

- Messages

- 917

- Reaction score

- 3

BB...

Get yourself a copy of Guy Lautard's "Machinist's Bedside Reader" vol. 1.

It has details on how to make a 'D' bit. The vertical part of the D needs to be at 51% of the diameter. (IOW you grind away 49% to the left of the D)

That book has a lot of good info and plans. IT's also a good general read.

Get yourself a copy of Guy Lautard's "Machinist's Bedside Reader" vol. 1.

It has details on how to make a 'D' bit. The vertical part of the D needs to be at 51% of the diameter. (IOW you grind away 49% to the left of the D)

That book has a lot of good info and plans. IT's also a good general read.

Twmaster

Well-Known Member

- Joined

- Oct 24, 2009

- Messages

- 917

- Reaction score

- 3

I understand it's often called 'silver steel' outside the USA...

EDIT: Silver Steel seems to be it.

http://en.wikipedia.org/wiki/Silver_steel

EDIT: Silver Steel seems to be it.

http://en.wikipedia.org/wiki/Silver_steel

OK, I think I got the picture. I would imagine they have to be clamped in the tool holder with an over hang that is short as possible to prevent wobble?

Just to put you back on track. A d-bit is used from the tailstock NOT your toolpost. It is used the same way as a machine reamer.

For a fairly good description of 'How to', I showed how to make a tapered one in this post.

http://madmodder.net/index.php?topic=2265.msg23824#msg23824

A little further down, it shows it in use.

Hope it is of help.

Blogs

Take a look in the tool catalogs for "half-round" drills.

http://www1.mscdirect.com/Half-Round-Drills/Drills/Cutting-Tools/s0000000617.HTML

You can modify the tip for use as a reamer easily enough.

I have a bunch of them stashed away. They come in handy sometimes. They can be made into nice little woodworking gouges too, if need be.

They are not that difficult or time consuming to make, but options are good ;D!

Kevin

http://www1.mscdirect.com/Half-Round-Drills/Drills/Cutting-Tools/s0000000617.HTML

You can modify the tip for use as a reamer easily enough.

I have a bunch of them stashed away. They come in handy sometimes. They can be made into nice little woodworking gouges too, if need be.

They are not that difficult or time consuming to make, but options are good ;D!

Kevin

Similar threads

- Replies

- 24

- Views

- 2K

- Replies

- 18

- Views

- 1K